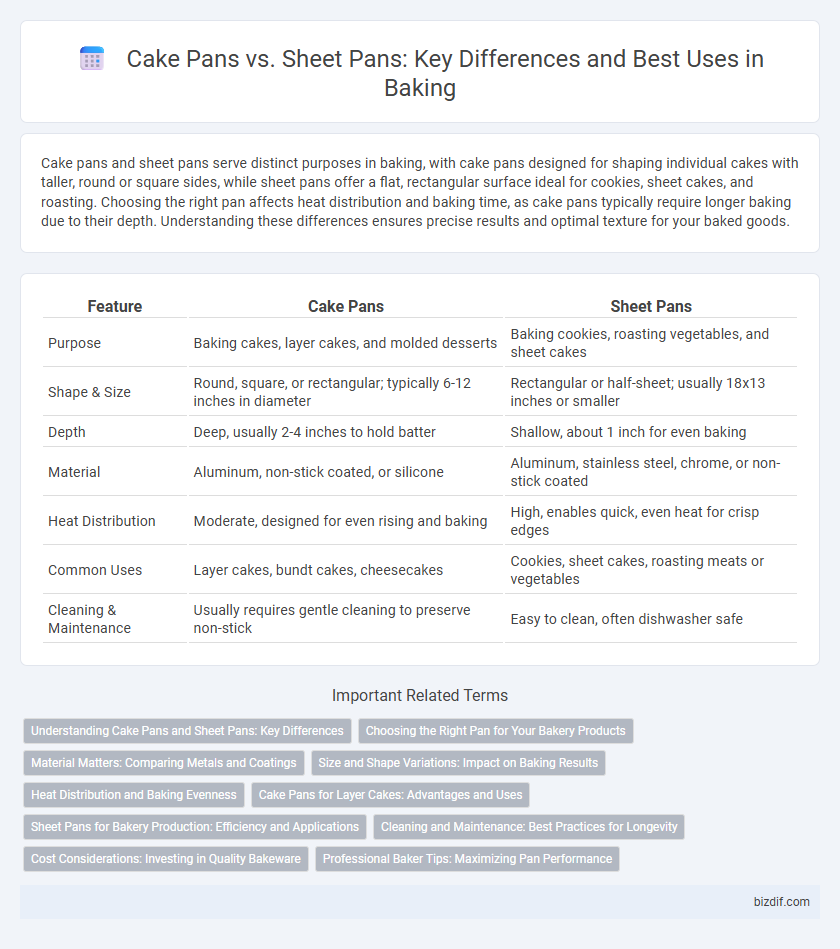

Cake pans and sheet pans serve distinct purposes in baking, with cake pans designed for shaping individual cakes with taller, round or square sides, while sheet pans offer a flat, rectangular surface ideal for cookies, sheet cakes, and roasting. Choosing the right pan affects heat distribution and baking time, as cake pans typically require longer baking due to their depth. Understanding these differences ensures precise results and optimal texture for your baked goods.

Table of Comparison

| Feature | Cake Pans | Sheet Pans |

|---|---|---|

| Purpose | Baking cakes, layer cakes, and molded desserts | Baking cookies, roasting vegetables, and sheet cakes |

| Shape & Size | Round, square, or rectangular; typically 6-12 inches in diameter | Rectangular or half-sheet; usually 18x13 inches or smaller |

| Depth | Deep, usually 2-4 inches to hold batter | Shallow, about 1 inch for even baking |

| Material | Aluminum, non-stick coated, or silicone | Aluminum, stainless steel, chrome, or non-stick coated |

| Heat Distribution | Moderate, designed for even rising and baking | High, enables quick, even heat for crisp edges |

| Common Uses | Layer cakes, bundt cakes, cheesecakes | Cookies, sheet cakes, roasting meats or vegetables |

| Cleaning & Maintenance | Usually requires gentle cleaning to preserve non-stick | Easy to clean, often dishwasher safe |

Understanding Cake Pans and Sheet Pans: Key Differences

Cake pans are specifically designed with deep, rounded sides to support the rise of batter for cakes, ensuring even cooking and maintaining shape integrity, whereas sheet pans have shallow, flat surfaces ideal for baking thin, evenly cooked items like cookies or roasting vegetables. Cake pans vary in shapes such as round, square, or loaf, and typically measure from 6 to 12 inches in diameter or length, while sheet pans come in standard sizes like half-sheet (18x13 inches) or quarter-sheet (9x13 inches), providing versatility for various baking needs. Understanding these key differences helps bakers select the right pan to achieve optimal texture, structure, and baking results for each recipe.

Choosing the Right Pan for Your Bakery Products

Cake pans are designed with taller sides to support rising batters, making them ideal for layered cakes and detailed shapes, while sheet pans offer a flat, spacious surface perfect for cookies, brownies, and roasting. Choosing the right pan depends on the desired texture and presentation; cake pans ensure even vertical baking, whereas sheet pans promote uniform browning and faster cooking due to their larger surface area. Professional bakeries often use specific pan materials like aluminum for better heat conduction and non-stick coatings to enhance product release and cleanup efficiency.

Material Matters: Comparing Metals and Coatings

Cake pans and sheet pans differ significantly in material composition and coating, impacting baking performance and durability. Aluminum cake pans offer excellent heat conductivity and often feature nonstick coatings like silicone or ceramic for easy release, while steel sheet pans provide superior durability with a heavier gauge and typically have a seasoned or nonstick surface suited for high-temperature baking. Choosing the right metal and coating depends on desired heat distribution, maintenance ease, and the type of baked goods produced.

Size and Shape Variations: Impact on Baking Results

Cake pans typically come in round, square, or rectangular shapes with deeper sides ranging from 2 to 4 inches, allowing for taller, layered cakes. Sheet pans are shallower, usually around 1 inch deep, designed in larger rectangular or half-sheet sizes for even baking of cookies, bars, or sheet cakes. The size and depth variations influence heat distribution and baking time, with cake pans producing moist, evenly risen layers while sheet pans yield thinner, crispier results.

Heat Distribution and Baking Evenness

Cake pans, typically made from heavier materials like aluminum or steel with non-stick coatings, offer superior heat retention and promote even baking by distributing heat uniformly across their curved surfaces. Sheet pans, often lighter and with a larger flat surface area, can experience uneven heat distribution, especially at the edges, leading to variations in browning and doneness. Choosing the right pan impacts baking results, as cake pans help maintain moisture and rise evenly, while sheet pans excel in producing crisp edges but may require rotation for consistent baking.

Cake Pans for Layer Cakes: Advantages and Uses

Cake pans for layer cakes offer precise depth and shape, ensuring even batter distribution and consistent baking results critical for professional-quality layers. These pans typically feature high sides and non-stick surfaces, facilitating easy removal and clean edges that enhance the cake's presentation. Using cake pans optimizes heat conduction, which prevents uneven rising and promotes uniform texture essential for multi-tiered cakes and intricate dessert designs.

Sheet Pans for Bakery Production: Efficiency and Applications

Sheet pans, essential in bakery production, offer superior efficiency due to their large surface area, enabling simultaneous baking of multiple items such as cookies, pastries, and bread rolls. Their uniform heat distribution ensures consistent baking results, critical for high-volume commercial bakeries aiming to optimize throughput and maintain product quality. Versatility in size and material options further enhances their application across various baking processes, making sheet pans a staple for scalable bakery operations.

Cleaning and Maintenance: Best Practices for Longevity

Cake pans require gentle cleaning with warm, soapy water and a soft sponge to prevent scratches and maintain their non-stick coating, while sheet pans often need more robust scrubbing to remove baked-on residue. Avoiding harsh abrasives and dishwasher cycles helps extend the lifespan of both types, preserving their surface integrity. Regular seasoning of carbon steel sheet pans can prevent rust and enhance performance, whereas non-stick cake pans benefit from occasional oiling before use.

Cost Considerations: Investing in Quality Bakeware

Investing in quality cake pans often requires a higher upfront cost compared to sheet pans, but their specialized design ensures even heat distribution and precise baking results, which reduces waste and enhances product consistency. Sheet pans, commonly used for baking cookies and roasting, offer versatility and affordability but may sacrifice some precision needed for delicate cake textures. Balancing the budget with the intended baking purpose helps maximize long-term value and efficiency in the bakery.

Professional Baker Tips: Maximizing Pan Performance

Professional bakers maximize cake pan performance by selecting the right material and size--aluminum pans offer even heat distribution for consistent baking, while non-stick coatings simplify release and cleanup. Sheet pans, typically larger and flatter, excel for cookies and roasting but require precise temperature control to avoid uneven cooking or browning. Using parchment paper or silicone liners enhances pan longevity and ensures optimal product texture, crucial for high-volume bakery operations.

Cake pans vs Sheet pans Infographic

bizdif.com

bizdif.com