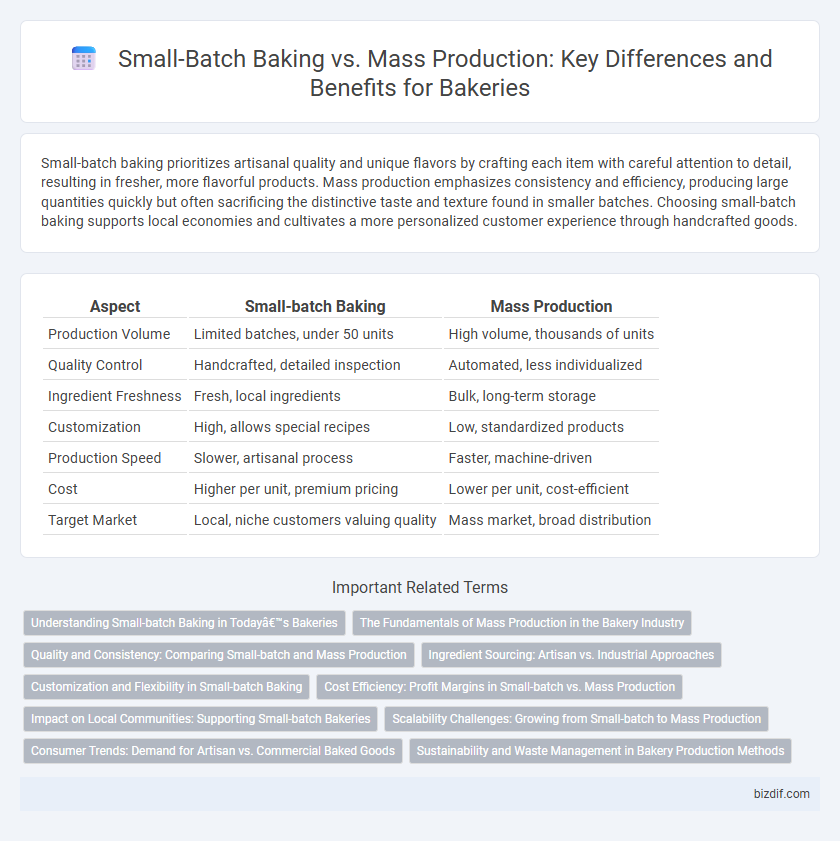

Small-batch baking prioritizes artisanal quality and unique flavors by crafting each item with careful attention to detail, resulting in fresher, more flavorful products. Mass production emphasizes consistency and efficiency, producing large quantities quickly but often sacrificing the distinctive taste and texture found in smaller batches. Choosing small-batch baking supports local economies and cultivates a more personalized customer experience through handcrafted goods.

Table of Comparison

| Aspect | Small-batch Baking | Mass Production |

|---|---|---|

| Production Volume | Limited batches, under 50 units | High volume, thousands of units |

| Quality Control | Handcrafted, detailed inspection | Automated, less individualized |

| Ingredient Freshness | Fresh, local ingredients | Bulk, long-term storage |

| Customization | High, allows special recipes | Low, standardized products |

| Production Speed | Slower, artisanal process | Faster, machine-driven |

| Cost | Higher per unit, premium pricing | Lower per unit, cost-efficient |

| Target Market | Local, niche customers valuing quality | Mass market, broad distribution |

Understanding Small-batch Baking in Today’s Bakeries

Small-batch baking emphasizes artisanal techniques and high-quality ingredients, producing limited quantities that enhance freshness and flavor. It allows bakers to maintain control over each step, ensuring unique textures and taste profiles compared to mass production. This approach meets growing consumer demand for handcrafted, specialty baked goods in today's market.

The Fundamentals of Mass Production in the Bakery Industry

Mass production in the bakery industry relies on automated machinery and standardized processes to produce large volumes of baked goods efficiently. This approach emphasizes consistency, speed, and cost reduction while maintaining quality standards. Key components include mechanized mixing, continuous baking ovens, and packaging lines, enabling bakeries to meet high consumer demand economically.

Quality and Consistency: Comparing Small-batch and Mass Production

Small-batch baking prioritizes quality by allowing bakers to carefully monitor ingredients and processes, resulting in artisanal flavors and textures. Mass production ensures consistency through automated systems and standardized procedures, producing uniform products at scale. While small-batch products offer superior freshness and unique characteristics, mass production excels in delivering reliable quality across large quantities.

Ingredient Sourcing: Artisan vs. Industrial Approaches

Small-batch baking emphasizes sourcing premium, locally-grown ingredients that ensure superior flavor and freshness, appealing to discerning customers seeking artisanal quality. In contrast, mass production relies on standardized, industrial-grade ingredients sourced in bulk to optimize cost-efficiency and consistent output. Artisan ingredient sourcing supports sustainable agriculture and traceability, while industrial approaches prioritize scalability and shelf life for widespread distribution.

Customization and Flexibility in Small-batch Baking

Small-batch baking allows for greater customization by enabling bakers to adjust recipes and ingredients according to customer preferences or seasonal availability. This flexibility supports unique product offerings, such as gluten-free or vegan options, that are often not feasible in mass production. Small-batch methods also ensure fresher products with tailored flavors and textures, enhancing overall customer satisfaction.

Cost Efficiency: Profit Margins in Small-batch vs. Mass Production

Small-batch baking typically incurs higher per-unit costs due to limited economies of scale, impacting profit margins compared to mass production which benefits from bulk purchasing and automated processes, lowering overall expenses. Mass production enables bakeries to achieve greater cost efficiency through streamlined operations and reduced labor per item, thereby increasing profit margins on high volume output. However, small-batch baking can command premium pricing by emphasizing artisanal quality and fresh ingredients, partially offsetting higher production costs with niche market appeal.

Impact on Local Communities: Supporting Small-batch Bakeries

Small-batch baking fosters local economies by sourcing ingredients from nearby farmers and creating jobs within the community, enhancing economic resilience. These bakeries prioritize artisanal quality and unique flavors, attracting customers who value craftsmanship over mass-produced uniformity. Supporting small-batch bakeries strengthens community identity and promotes sustainable food systems compared to large-scale mass production.

Scalability Challenges: Growing from Small-batch to Mass Production

Small-batch baking prioritizes artisanal quality and flavor but faces significant scalability challenges when transitioning to mass production, including maintaining product consistency and managing ingredient sourcing. Equipment upgrades and streamlined workflows are essential to meet increased demand without compromising the integrity of baked goods. Ensuring quality control and efficient supply chain logistics becomes critical as bakeries expand from handcrafted batches to large-scale manufacturing.

Consumer Trends: Demand for Artisan vs. Commercial Baked Goods

Consumer preferences increasingly favor small-batch baking due to its emphasis on artisanal quality, unique flavors, and handcrafted techniques, contrasting with the uniformity of mass-produced goods. Artisan baked goods often feature locally sourced ingredients and traditional methods, appealing to health-conscious and ethically driven buyers. Mass production caters to convenience and affordability but struggles to meet the growing demand for authenticity and premium bakery experiences.

Sustainability and Waste Management in Bakery Production Methods

Small-batch baking reduces food waste by producing only what is needed, enhancing sustainability through localized ingredient sourcing and minimizing excess inventory. Mass production often results in surplus goods and higher energy consumption, challenging effective waste management due to the scale of output. Sustainable bakery production methods prioritize precise demand forecasting and recyclable packaging to mitigate environmental impact.

Small-batch Baking vs Mass Production Infographic

bizdif.com

bizdif.com