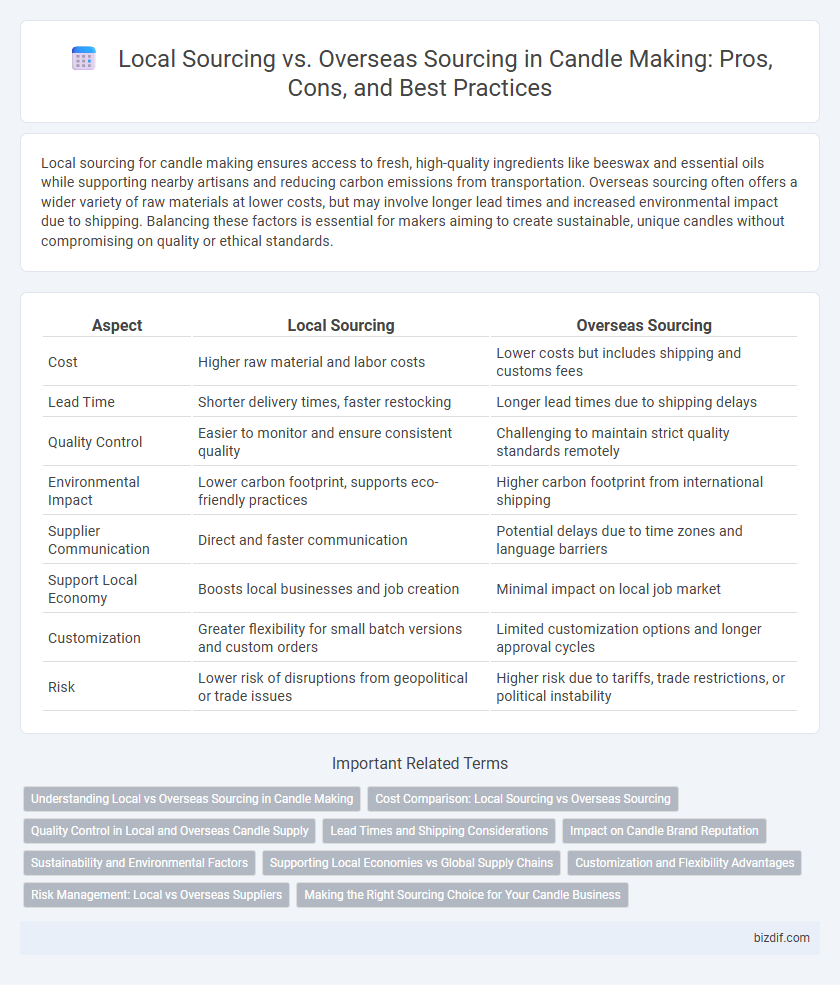

Local sourcing for candle making ensures access to fresh, high-quality ingredients like beeswax and essential oils while supporting nearby artisans and reducing carbon emissions from transportation. Overseas sourcing often offers a wider variety of raw materials at lower costs, but may involve longer lead times and increased environmental impact due to shipping. Balancing these factors is essential for makers aiming to create sustainable, unique candles without compromising on quality or ethical standards.

Table of Comparison

| Aspect | Local Sourcing | Overseas Sourcing |

|---|---|---|

| Cost | Higher raw material and labor costs | Lower costs but includes shipping and customs fees |

| Lead Time | Shorter delivery times, faster restocking | Longer lead times due to shipping delays |

| Quality Control | Easier to monitor and ensure consistent quality | Challenging to maintain strict quality standards remotely |

| Environmental Impact | Lower carbon footprint, supports eco-friendly practices | Higher carbon footprint from international shipping |

| Supplier Communication | Direct and faster communication | Potential delays due to time zones and language barriers |

| Support Local Economy | Boosts local businesses and job creation | Minimal impact on local job market |

| Customization | Greater flexibility for small batch versions and custom orders | Limited customization options and longer approval cycles |

| Risk | Lower risk of disruptions from geopolitical or trade issues | Higher risk due to tariffs, trade restrictions, or political instability |

Understanding Local vs Overseas Sourcing in Candle Making

Local sourcing in candle making ensures fresher, artisanal ingredients like beeswax and essential oils, supporting nearby farmers and reducing carbon footprint. Overseas sourcing offers access to a wider variety of raw materials at competitive prices but may involve longer lead times and increased transportation emissions. Evaluating factors such as cost, quality, sustainability, and supply chain reliability helps candle makers decide the optimal sourcing strategy for their business.

Cost Comparison: Local Sourcing vs Overseas Sourcing

Local sourcing for candle making often incurs higher raw material and labor costs but reduces shipping expenses and delivery times, enhancing inventory management. Overseas sourcing typically offers lower prices on bulk wax, fragrance oils, and packaging but includes higher shipping fees, customs duties, and longer lead times that impact cash flow. Evaluating total landed cost, including tariffs and potential delays, is crucial for candle makers balancing cost efficiency with supply chain reliability.

Quality Control in Local and Overseas Candle Supply

Local sourcing of candle supplies allows for stricter quality control through direct inspection of raw materials and production processes, ensuring consistent fragrance, wax purity, and wick standards. Overseas sourcing often involves challenges in maintaining quality due to distance, communication barriers, and less frequent on-site supervision, which can lead to variability in candle burn time and scent throw. Establishing reliable overseas partnerships and implementing rigorous third-party inspections can mitigate some risks but generally cannot match the immediate oversight available in local sourcing.

Lead Times and Shipping Considerations

Local sourcing for candle making significantly reduces lead times by enabling faster access to raw materials like wax, wicks, and fragrance oils, which helps maintain efficient production schedules. Overseas sourcing often involves extended lead times due to longer transit durations, customs clearance, and potential delays in shipping lanes, impacting inventory reliability. Shipping considerations such as freight costs, packaging requirements, and potential risks of damage or loss also influence the choice between local and overseas suppliers for candle makers.

Impact on Candle Brand Reputation

Local sourcing for candle making enhances brand reputation by emphasizing sustainability, ethical practices, and community support, which resonates well with environmentally conscious consumers. Overseas sourcing may reduce production costs but can raise concerns about quality control, transparency, and labor standards that potentially harm a candle brand's image. Brands prioritizing local materials and artisans often gain trust and loyalty, boosting their market appeal in the competitive candle industry.

Sustainability and Environmental Factors

Local sourcing in candle making reduces carbon emissions by minimizing transportation distances and supports sustainable harvesting of raw materials like soy wax and beeswax. Overseas sourcing often involves higher energy consumption and greater ecological footprints due to long shipping routes and variable environmental regulations. Choosing locally sourced ingredients aligns with eco-friendly practices by fostering transparency, reducing packaging waste, and promoting renewable resource management.

Supporting Local Economies vs Global Supply Chains

Local sourcing in candle making promotes sustainable practices by reducing transportation emissions and supporting small-scale farmers and artisans, fostering economic resilience within communities. Overseas sourcing offers access to a broader range of raw materials and cost efficiencies but relies heavily on complex global supply chains that may face disruptions and higher carbon footprints. Balancing local economies with global supply chains ensures ethical production, quality consistency, and environmental responsibility in the candle industry.

Customization and Flexibility Advantages

Local sourcing in candle making offers superior customization and flexibility by enabling direct communication with suppliers, allowing for rapid adjustments to materials, scents, and designs. This proximity reduces lead times and facilitates small-batch production, critical for bespoke candle collections. Overseas sourcing often involves longer turnaround times and rigid order quantities, limiting the ability to quickly adapt to unique customer preferences or market trends.

Risk Management: Local vs Overseas Suppliers

Local sourcing in candle making minimizes supply chain disruptions by reducing lead times and enhancing quality control through closer supplier relationships. Overseas sourcing introduces risks such as longer shipping delays, customs complications, and potential quality inconsistencies, impacting production schedules and product reliability. Effective risk management in candle manufacturing prioritizes supplier evaluation, contingency planning, and leveraging local suppliers to ensure a stable and predictable supply chain.

Making the Right Sourcing Choice for Your Candle Business

Local sourcing for candle making ensures higher quality control and faster turnaround times, enhancing product consistency and customer satisfaction. Overseas sourcing can reduce material costs but may introduce longer lead times and potential quality risks, impacting overall production schedules. Evaluating supplier reliability, cost-effectiveness, and delivery efficiency is crucial for making the right sourcing choice that supports sustainable growth in the candle business.

Local sourcing vs Overseas sourcing Infographic

bizdif.com

bizdif.com