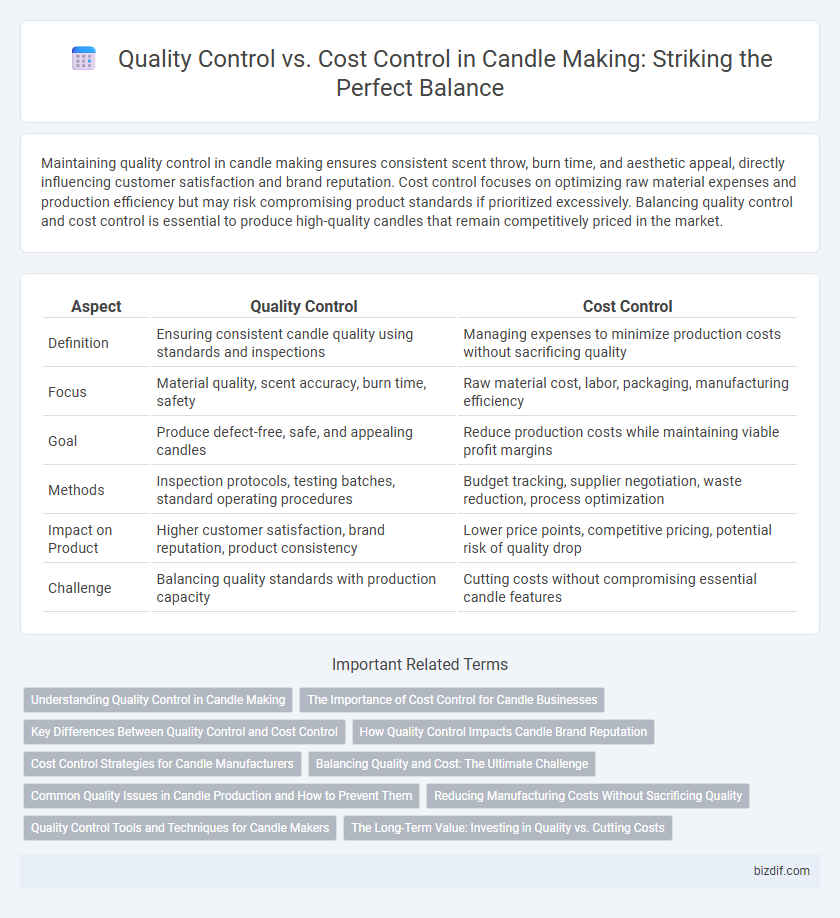

Maintaining quality control in candle making ensures consistent scent throw, burn time, and aesthetic appeal, directly influencing customer satisfaction and brand reputation. Cost control focuses on optimizing raw material expenses and production efficiency but may risk compromising product standards if prioritized excessively. Balancing quality control and cost control is essential to produce high-quality candles that remain competitively priced in the market.

Table of Comparison

| Aspect | Quality Control | Cost Control |

|---|---|---|

| Definition | Ensuring consistent candle quality using standards and inspections | Managing expenses to minimize production costs without sacrificing quality |

| Focus | Material quality, scent accuracy, burn time, safety | Raw material cost, labor, packaging, manufacturing efficiency |

| Goal | Produce defect-free, safe, and appealing candles | Reduce production costs while maintaining viable profit margins |

| Methods | Inspection protocols, testing batches, standard operating procedures | Budget tracking, supplier negotiation, waste reduction, process optimization |

| Impact on Product | Higher customer satisfaction, brand reputation, product consistency | Lower price points, competitive pricing, potential risk of quality drop |

| Challenge | Balancing quality standards with production capacity | Cutting costs without compromising essential candle features |

Understanding Quality Control in Candle Making

Quality control in candle making ensures consistent fragrance intensity, uniform burn time, and flawless appearance, which directly impacts customer satisfaction and brand reputation. It involves rigorous testing of wax blend composition, wick material, and scent load to maintain safety standards and product performance. Prioritizing quality control minimizes defects and returns, ultimately supporting long-term profitability despite initial higher production costs.

The Importance of Cost Control for Candle Businesses

Effective cost control in candle making ensures materials like wax, fragrance oils, and wicks are sourced at optimal prices to maintain profitability. Balancing expenses without compromising product quality allows candle businesses to compete in markets driven by price sensitivity and consumer expectations. Efficient cost management directly impacts cash flow, enabling sustainable growth and investment in innovation within the candle industry.

Key Differences Between Quality Control and Cost Control

Quality control in candle making ensures consistent product standards by monitoring factors such as wax purity, wick size, and fragrance oil concentration, directly impacting customer satisfaction and brand reputation. Cost control focuses on managing expenses related to raw materials, labor, and production processes to maximize profitability without compromising essential quality parameters. The key difference lies in quality control prioritizing product excellence, while cost control emphasizes financial efficiency throughout the manufacturing cycle.

How Quality Control Impacts Candle Brand Reputation

Implementing rigorous quality control in candle making ensures consistent product performance, safety, and aesthetic appeal, which significantly enhances a brand's reputation. High-quality candles with reliable burn times, non-toxic ingredients, and balanced fragrances build consumer trust and encourage repeat purchases. Neglecting quality control can lead to defects, customer complaints, and negative reviews that directly damage brand credibility and market positioning.

Cost Control Strategies for Candle Manufacturers

Cost control strategies for candle manufacturers include optimizing raw material procurement by sourcing wax, wicks, and fragrances in bulk to reduce unit costs. Implementing energy-efficient production processes and automating repetitive tasks decrease operational expenses while maintaining consistent output quality. Utilizing precise inventory management and demand forecasting minimizes waste and excess stock, further lowering overall manufacturing costs.

Balancing Quality and Cost: The Ultimate Challenge

Balancing quality and cost in candle making presents the ultimate challenge, as high-quality ingredients like premium wax and natural scents increase production expenses. Effective quality control ensures consistent burn time, scent throw, and aesthetic appeal, directly impacting customer satisfaction and brand reputation. Cost control involves strategic sourcing and efficient manufacturing processes to maintain profitability without compromising the candles' overall performance and safety standards.

Common Quality Issues in Candle Production and How to Prevent Them

Common quality issues in candle production include uneven burning, tunneling, and fragrance fading, which can be prevented by using high-grade wax, proper wick sizing, and stable fragrance load formulas. Implementing rigorous quality control measures such as batch testing, temperature monitoring, and consistent pouring techniques ensures product uniformity and customer satisfaction. Balancing quality control with cost control involves investing in reliable raw materials and equipment to minimize defects and reduce waste, ultimately enhancing production efficiency.

Reducing Manufacturing Costs Without Sacrificing Quality

Balancing quality control and cost control in candle making involves selecting premium raw materials that offer durability and consistency while optimizing production processes to minimize waste. Implementing precise temperature regulation and automated pouring techniques enhances product uniformity, reducing defects and rework costs. Streamlined supply chain management and bulk purchasing of high-quality wax, wicks, and fragrances contribute to lowering manufacturing costs without compromising the final candle quality.

Quality Control Tools and Techniques for Candle Makers

Quality control tools for candle makers include visual inspections, weight consistency checks, and fragrance testing to ensure each candle meets customer expectations. Techniques such as standardized melting points, wick performance analysis, and color fastness evaluations help maintain product reliability and safety. Implementing control charts and batch sampling further aids in identifying defects early, balancing high quality with efficient production costs.

The Long-Term Value: Investing in Quality vs. Cutting Costs

Investing in quality candle ingredients, such as premium wax and natural fragrances, ensures consistent burn times and customer satisfaction, which builds brand loyalty and long-term revenue. Cutting costs by using cheaper materials may increase short-term profits but often leads to defects, customer complaints, and product returns that damage reputation and reduce repeat sales. Prioritizing quality control fosters sustainable growth and higher lifetime customer value despite initial higher expenses.

Quality control vs Cost control Infographic

bizdif.com

bizdif.com