Polycarbonate barriers offer superior impact resistance and durability compared to acrylic shields, making them ideal for childproofing environments with pets. Unlike acrylic, polycarbonate is less prone to cracking and yellowing over time, ensuring long-lasting protection. Both materials are transparent and easy to clean, but polycarbonate provides enhanced safety benefits in high-activity areas.

Table of Comparison

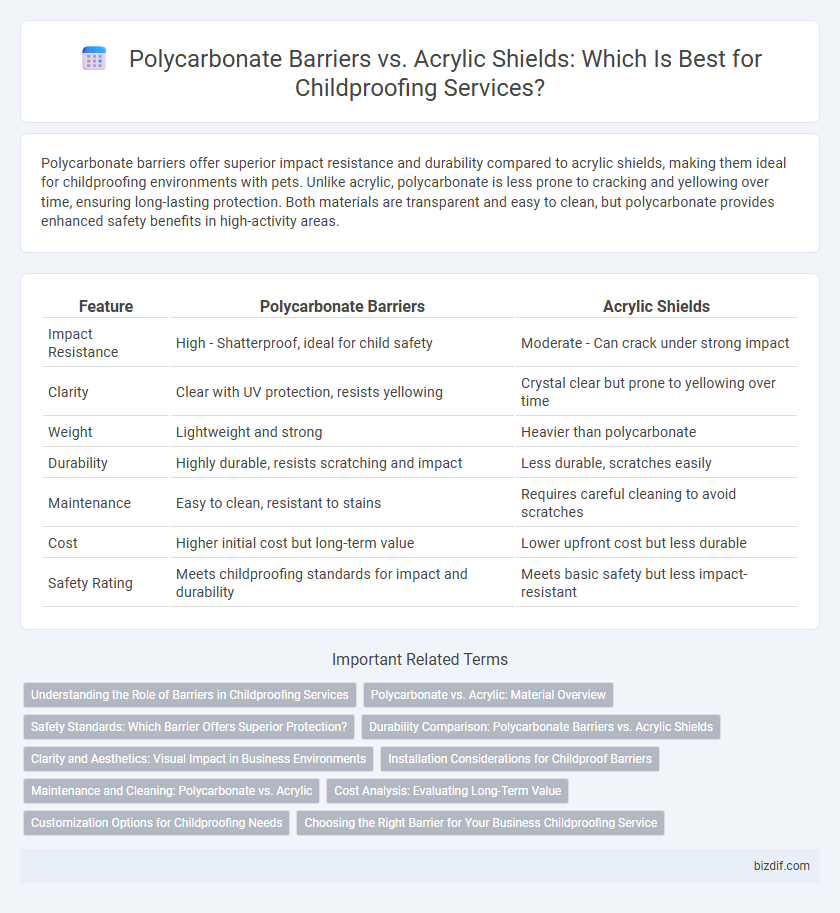

| Feature | Polycarbonate Barriers | Acrylic Shields |

|---|---|---|

| Impact Resistance | High - Shatterproof, ideal for child safety | Moderate - Can crack under strong impact |

| Clarity | Clear with UV protection, resists yellowing | Crystal clear but prone to yellowing over time |

| Weight | Lightweight and strong | Heavier than polycarbonate |

| Durability | Highly durable, resists scratching and impact | Less durable, scratches easily |

| Maintenance | Easy to clean, resistant to stains | Requires careful cleaning to avoid scratches |

| Cost | Higher initial cost but long-term value | Lower upfront cost but less durable |

| Safety Rating | Meets childproofing standards for impact and durability | Meets basic safety but less impact-resistant |

Understanding the Role of Barriers in Childproofing Services

Polycarbonate barriers offer superior impact resistance and durability, making them an ideal choice for childproofing services to prevent injuries from accidental collisions. Acrylic shields provide clear visibility and a lightweight option but are more prone to cracking under force, which may reduce effectiveness in high-traffic or play areas. Selecting the right material for barriers is essential in creating safe environments by minimizing hazards and ensuring long-lasting protection in homes and childcare settings.

Polycarbonate vs. Acrylic: Material Overview

Polycarbonate barriers offer superior impact resistance and durability compared to acrylic shields, making them ideal for high-traffic childproofing environments. Polycarbonate's inherent flexibility and higher tensile strength reduce the risk of cracking or shattering, unlike more brittle acrylic materials. Both materials provide clarity and UV resistance, but polycarbonate's robust performance under stress enhances safety in childproofing applications.

Safety Standards: Which Barrier Offers Superior Protection?

Polycarbonate barriers provide superior protection compared to acrylic shields due to their higher impact resistance and compliance with rigorous safety standards such as ASTM F1233. These barriers resist shattering under significant force, reducing the risk of injury in childproofing environments. Acrylic shields, while clear and cost-effective, are more prone to cracking and may not meet the highest safety certifications required for effective child protection.

Durability Comparison: Polycarbonate Barriers vs. Acrylic Shields

Polycarbonate barriers exhibit superior durability compared to acrylic shields, offering enhanced impact resistance and greater flexibility under stress. They are less prone to cracking or shattering, making them ideal for high-traffic childproofing settings. Acrylic shields, while more affordable and providing clearer visibility, tend to be more brittle and susceptible to damage from strong impacts or prolonged use.

Clarity and Aesthetics: Visual Impact in Business Environments

Polycarbonate barriers offer superior clarity and durability compared to acrylic shields, maintaining a crystal-clear view essential for professional business environments. Their high optical transparency ensures minimal distortion, enhancing the visual appeal while providing robust childproofing safety features. Acrylic shields, though aesthetically pleasing, tend to yellow and scratch over time, potentially diminishing the overall look and visual impact in commercial spaces.

Installation Considerations for Childproof Barriers

Polycarbonate barriers offer superior impact resistance and durability, making them ideal for high-traffic childproofing installations, while acrylic shields provide clarity and cost-effectiveness but require more careful handling during installation due to their brittleness. Installation of polycarbonate barriers often demands specialized tools and precise measurements to ensure secure fitting and enhanced safety for children, whereas acrylic shields can be installed with standard hardware but may need additional protective edging to prevent cracking. Choosing the right material hinges on the specific environment's risk factors and the need for long-term resilience versus aesthetic appeal.

Maintenance and Cleaning: Polycarbonate vs. Acrylic

Polycarbonate barriers offer superior resistance to scratching and impact, making them easier to maintain and clean without losing clarity over time. Acrylic shields, while more affordable, tend to scratch more easily, requiring gentler cleaning methods and frequent polishing to maintain a clear surface. Both materials can be cleaned with mild soap and water, but polycarbonate's durability ensures longer-lasting cleanliness and less frequent replacement in childproofing environments.

Cost Analysis: Evaluating Long-Term Value

Polycarbonate barriers offer higher impact resistance and durability compared to acrylic shields, making them a cost-effective choice for long-term childproofing solutions. Although acrylic shields have a lower upfront cost, their susceptibility to cracking and yellowing over time can lead to frequent replacements, increasing overall expenses. Investing in polycarbonate barriers reduces maintenance and replacement costs, providing better value in prolonged safety applications.

Customization Options for Childproofing Needs

Polycarbonate barriers offer superior customization options for childproofing needs, including tailored dimensions, thickness, and edge finishes that enhance durability and safety. Acrylic shields provide clear visibility but have limited flexibility in size and shape customization compared to polycarbonate. Opting for polycarbonate ensures a more adaptable solution that meets specific childproofing requirements in both residential and commercial settings.

Choosing the Right Barrier for Your Business Childproofing Service

Polycarbonate barriers offer superior impact resistance and durability compared to acrylic shields, making them ideal for high-traffic areas in childproofing services. Acrylic shields provide clearer visibility and are more cost-effective but may crack under heavy use. Selecting the right barrier depends on balancing safety requirements, budget constraints, and the specific environment of your business.

Polycarbonate Barriers vs Acrylic Shields Infographic

bizdif.com

bizdif.com