Lean consulting emphasizes eliminating waste and improving process flow to enhance efficiency, while Six Sigma consulting focuses on reducing variability and defect rates through data-driven methodologies. Both approaches aim to optimize organizational performance, yet Lean prioritizes speed and simplicity, whereas Six Sigma relies on statistical analysis for precision. Integrating Lean and Six Sigma techniques often results in comprehensive operational improvements combining waste reduction with quality control.

Table of Comparison

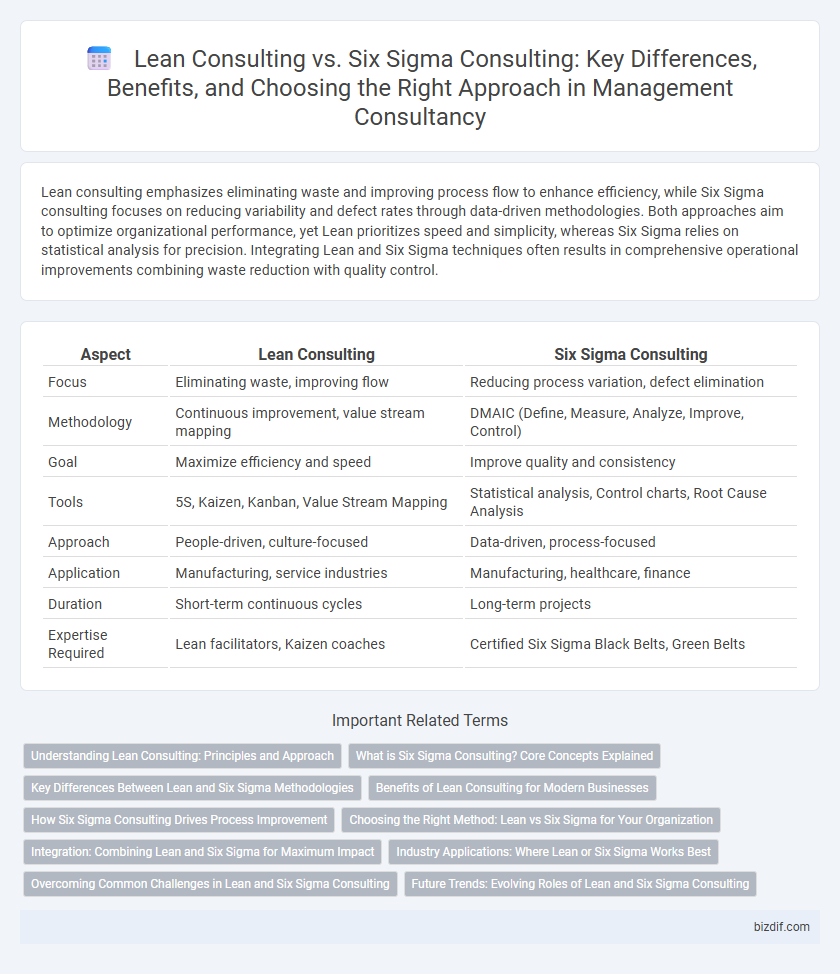

| Aspect | Lean Consulting | Six Sigma Consulting |

|---|---|---|

| Focus | Eliminating waste, improving flow | Reducing process variation, defect elimination |

| Methodology | Continuous improvement, value stream mapping | DMAIC (Define, Measure, Analyze, Improve, Control) |

| Goal | Maximize efficiency and speed | Improve quality and consistency |

| Tools | 5S, Kaizen, Kanban, Value Stream Mapping | Statistical analysis, Control charts, Root Cause Analysis |

| Approach | People-driven, culture-focused | Data-driven, process-focused |

| Application | Manufacturing, service industries | Manufacturing, healthcare, finance |

| Duration | Short-term continuous cycles | Long-term projects |

| Expertise Required | Lean facilitators, Kaizen coaches | Certified Six Sigma Black Belts, Green Belts |

Understanding Lean Consulting: Principles and Approach

Lean consulting centers on eliminating waste and optimizing workflows to enhance operational efficiency and reduce costs. It emphasizes continuous improvement through value stream mapping, empowering employees, and fostering a culture of sustained process refinement. The approach prioritizes customer value by streamlining processes and minimizing non-value-added activities across manufacturing, healthcare, and service industries.

What is Six Sigma Consulting? Core Concepts Explained

Six Sigma consulting is a data-driven approach focused on improving business processes by reducing defects and variability through statistical analysis. Key concepts include DMAIC (Define, Measure, Analyze, Improve, Control), which guides problem-solving and process optimization. Six Sigma consultants utilize tools like process mapping, root cause analysis, and control charts to enhance quality and operational efficiency.

Key Differences Between Lean and Six Sigma Methodologies

Lean consulting emphasizes waste reduction and process flow optimization to enhance efficiency and speed, focusing primarily on eliminating non-value-added activities. Six Sigma consulting targets quality improvement by identifying and reducing process variation through data-driven statistical analysis and defect reduction. The key difference lies in Lean's focus on speed and waste, whereas Six Sigma prioritizes precision and defect control in process improvement initiatives.

Benefits of Lean Consulting for Modern Businesses

Lean consulting enhances operational efficiency by systematically eliminating waste and streamlining processes, resulting in faster delivery times and reduced costs. Modern businesses benefit from Lean's emphasis on continuous improvement and customer value, driving higher quality and increased flexibility to adapt to market changes. This approach fosters employee engagement and innovation, promoting sustainable growth and competitive advantage in dynamic industries.

How Six Sigma Consulting Drives Process Improvement

Six Sigma consulting drives process improvement by utilizing data-driven methodologies to reduce defects and variability in business operations, resulting in enhanced quality and efficiency. The disciplined approach employs DMAIC (Define, Measure, Analyze, Improve, Control) frameworks to identify root causes of inefficiencies and implement statistically validated solutions. This focus on measurable results and continuous process control elevates operational performance beyond traditional lean techniques centered on waste elimination.

Choosing the Right Method: Lean vs Six Sigma for Your Organization

Choosing the right method between Lean consulting and Six Sigma consulting depends on your organization's specific goals and challenges; Lean focuses on eliminating waste and improving process flow, while Six Sigma emphasizes reducing variation and enhancing quality through data-driven analysis. Organizations seeking rapid efficiency gains and streamlined operations often benefit more from Lean, whereas those addressing complex quality issues and aiming for statistical process control lean towards Six Sigma. Evaluating your organization's pain points, process maturity, and desired outcomes ensures a tailored approach that maximizes operational performance and customer satisfaction.

Integration: Combining Lean and Six Sigma for Maximum Impact

Integrating Lean Consulting and Six Sigma Consulting creates a powerful approach that leverages Lean's focus on waste reduction and process flow with Six Sigma's emphasis on reducing variability and improving quality. This combined methodology enhances operational efficiency by streamlining processes while systematically solving complex problems using data-driven tools like DMAIC (Define, Measure, Analyze, Improve, Control). Organizations adopting Lean Six Sigma achieve sustained improvements, increased customer satisfaction, and significant cost savings through comprehensive performance optimization.

Industry Applications: Where Lean or Six Sigma Works Best

Lean consulting excels in industries with high process variability and waste, such as manufacturing, logistics, and healthcare, by streamlining workflows and improving efficiency. Six Sigma consulting is highly effective in sectors demanding strict quality control and defect reduction, including aerospace, automotive, and electronics, where statistical analysis drives precision improvements. Combining Lean and Six Sigma methodologies often yields optimal results in complex environments like pharmaceuticals and financial services, integrating waste reduction with data-driven quality enhancements.

Overcoming Common Challenges in Lean and Six Sigma Consulting

Overcoming common challenges in Lean and Six Sigma consulting requires addressing resistance to change by fostering a culture of continuous improvement and employee engagement. Effective data management and accurate measurement systems are critical for identifying process inefficiencies and driving informed decision-making. Integrating Lean's waste reduction techniques with Six Sigma's focus on variability control enhances overall operational excellence.

Future Trends: Evolving Roles of Lean and Six Sigma Consulting

Lean consulting and Six Sigma consulting are evolving to incorporate advanced data analytics and AI-driven process optimization, enhancing predictive capabilities and real-time decision-making. The future trends emphasize integrating Lean's waste reduction with Six Sigma's defect control, promoting hybrid methodologies tailored to digital transformation in industries. Consultants increasingly focus on sustainability and agility, addressing complex, dynamic markets through continuous improvement frameworks that leverage emerging technologies.

Lean Consulting vs Six Sigma Consulting Infographic

bizdif.com

bizdif.com