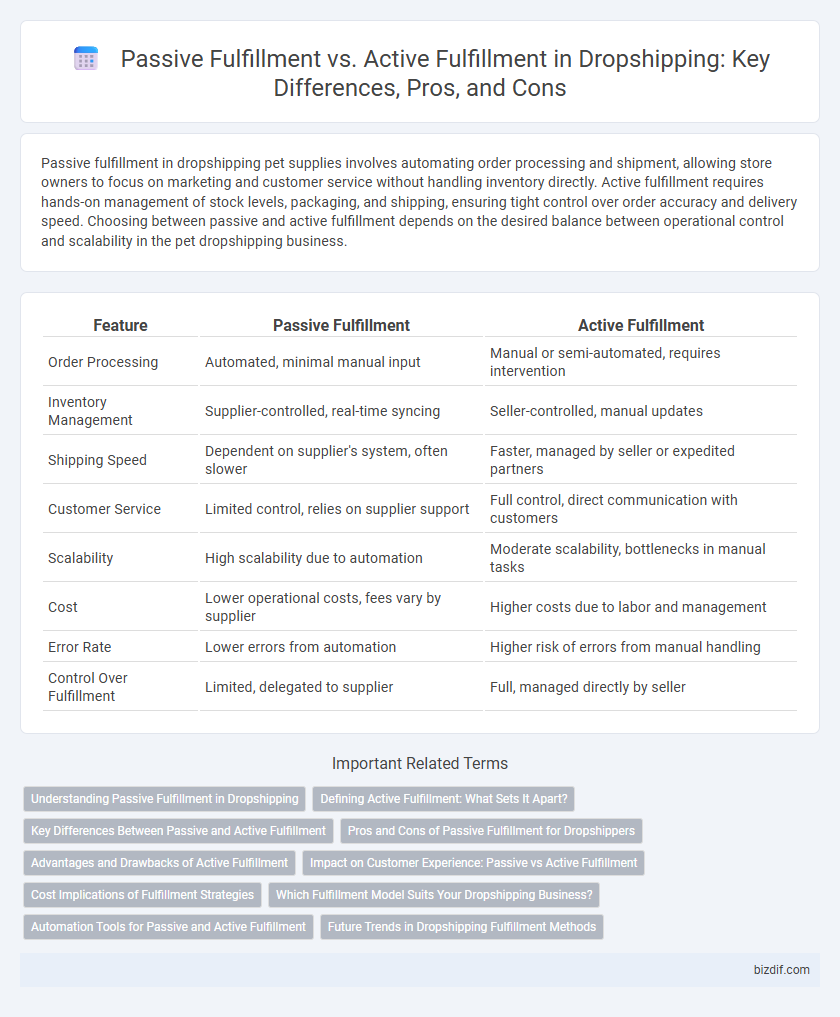

Passive fulfillment in dropshipping pet supplies involves automating order processing and shipment, allowing store owners to focus on marketing and customer service without handling inventory directly. Active fulfillment requires hands-on management of stock levels, packaging, and shipping, ensuring tight control over order accuracy and delivery speed. Choosing between passive and active fulfillment depends on the desired balance between operational control and scalability in the pet dropshipping business.

Table of Comparison

| Feature | Passive Fulfillment | Active Fulfillment |

|---|---|---|

| Order Processing | Automated, minimal manual input | Manual or semi-automated, requires intervention |

| Inventory Management | Supplier-controlled, real-time syncing | Seller-controlled, manual updates |

| Shipping Speed | Dependent on supplier's system, often slower | Faster, managed by seller or expedited partners |

| Customer Service | Limited control, relies on supplier support | Full control, direct communication with customers |

| Scalability | High scalability due to automation | Moderate scalability, bottlenecks in manual tasks |

| Cost | Lower operational costs, fees vary by supplier | Higher costs due to labor and management |

| Error Rate | Lower errors from automation | Higher risk of errors from manual handling |

| Control Over Fulfillment | Limited, delegated to supplier | Full, managed directly by seller |

Understanding Passive Fulfillment in Dropshipping

Passive fulfillment in dropshipping involves the supplier handling inventory storage, packaging, and shipping directly to customers, enabling the retailer to operate without managing physical products. This model minimizes upfront costs and operational complexities, allowing entrepreneurs to scale their online stores efficiently. Understanding passive fulfillment is crucial for dropshippers seeking low-risk entry into e-commerce by leveraging automated order processing and supplier partnerships.

Defining Active Fulfillment: What Sets It Apart?

Active fulfillment in dropshipping involves direct control over inventory management, order processing, and shipping logistics, distinguishing it from passive fulfillment where these tasks are outsourced to suppliers. This hands-on approach allows for real-time inventory updates, customized packaging, and faster response to customer inquiries, enhancing the overall customer experience. By actively managing fulfillment, businesses can reduce errors, improve delivery times, and maintain higher quality standards.

Key Differences Between Passive and Active Fulfillment

Passive fulfillment in dropshipping involves automating order processing through third-party suppliers who handle inventory and shipping, minimizing seller involvement and reducing operational complexity. Active fulfillment requires the seller to manage inventory, pick and pack orders, and coordinate shipping, providing greater control but demanding more time and resources. Key differences include the level of seller engagement, control over logistics, and the operational workload required to fulfill customer orders.

Pros and Cons of Passive Fulfillment for Dropshippers

Passive fulfillment in dropshipping involves outsourcing order processing entirely to suppliers, allowing dropshippers to focus on marketing and customer acquisition without handling inventory or shipping logistics. Pros include reduced operational workload and lower upfront costs, enabling scalability and flexibility. Cons consist of limited control over shipping times and product quality, which can lead to customer dissatisfaction and potential damage to brand reputation.

Advantages and Drawbacks of Active Fulfillment

Active fulfillment in dropshipping offers greater control over inventory quality, order accuracy, and shipping speed, enhancing customer satisfaction and brand reputation. This hands-on approach allows for immediate problem resolution and customization of packaging, fostering brand loyalty and differentiation. However, active fulfillment requires more time, effort, and resources, potentially increasing operational costs and complexity compared to passive fulfillment models.

Impact on Customer Experience: Passive vs Active Fulfillment

Passive fulfillment often leads to slower shipping times and less frequent updates, which can negatively impact customer satisfaction and trust. Active fulfillment prioritizes real-time inventory management and faster order processing, resulting in improved delivery speed and transparency. Enhanced communication and reliability in active fulfillment directly contribute to a better overall customer experience in dropshipping.

Cost Implications of Fulfillment Strategies

Passive fulfillment in dropshipping typically incurs lower upfront costs due to minimal inventory management and reliance on suppliers for order processing, reducing warehousing expenses significantly. Active fulfillment involves higher expenses related to purchasing stock, storage, and handling, which can increase operational costs but improve control over product quality and shipping speed. Evaluating the balance between cost savings and service quality is crucial for optimizing fulfillment strategies and maintaining profitability in dropshipping businesses.

Which Fulfillment Model Suits Your Dropshipping Business?

Passive fulfillment relies on third-party suppliers to handle inventory storage, packaging, and shipping, allowing dropshippers to focus on marketing and sales without managing logistics. Active fulfillment involves the dropshipper taking direct control over inventory and order processing, offering greater control and faster response times but requiring more resources and management. Choosing the right fulfillment model depends on your business scale, desired control level, and operational capacity to ensure efficient order handling and customer satisfaction.

Automation Tools for Passive and Active Fulfillment

Automation tools for passive fulfillment in dropshipping include platforms like Oberlo and Dropified, which streamline product import, order processing, and inventory management without constant manual input. Active fulfillment leverages advanced tools such as ShipStation and Inventory Source, enabling real-time order tracking, personalized packaging, and direct supplier communication to maintain higher control over fulfillment processes. Integrating these automation solutions enhances efficiency, reduces errors, and optimizes the supply chain tailored to the dropshipping business model.

Future Trends in Dropshipping Fulfillment Methods

Future trends in dropshipping fulfillment methods emphasize automation and AI-driven passive fulfillment, reducing manual intervention and accelerating delivery times. Integration of real-time inventory tracking and predictive analytics enhances active fulfillment by enabling dynamic order management and personalized customer experiences. The rise of eco-friendly packaging and local micro-warehouses will optimize both fulfillment approaches, improving sustainability and operational efficiency.

Passive Fulfillment vs Active Fulfillment Infographic

bizdif.com

bizdif.com