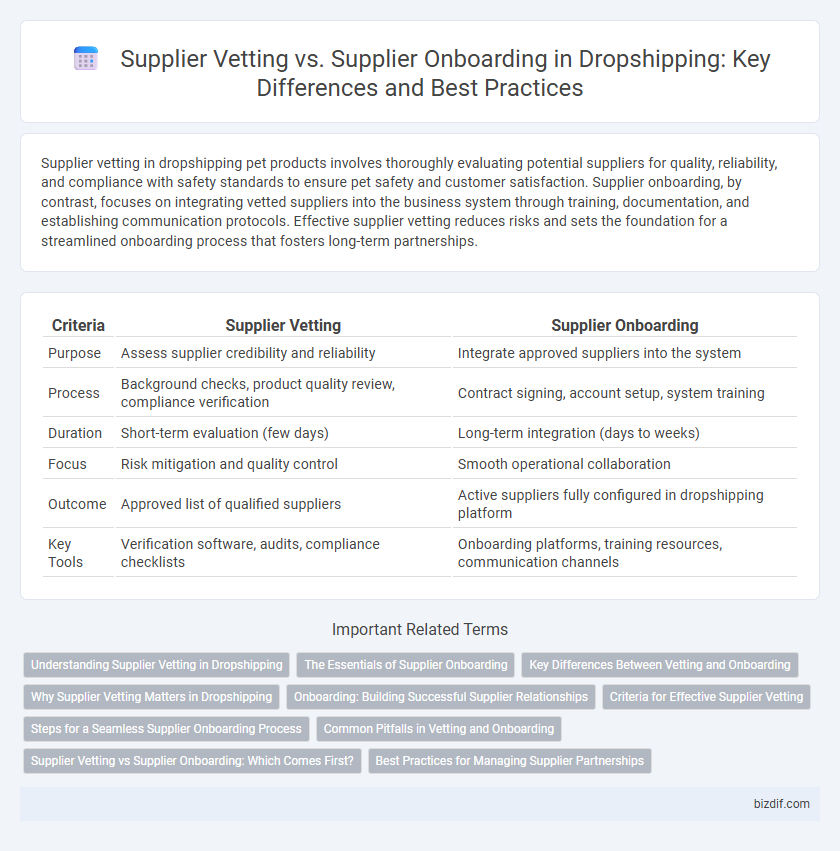

Supplier vetting in dropshipping pet products involves thoroughly evaluating potential suppliers for quality, reliability, and compliance with safety standards to ensure pet safety and customer satisfaction. Supplier onboarding, by contrast, focuses on integrating vetted suppliers into the business system through training, documentation, and establishing communication protocols. Effective supplier vetting reduces risks and sets the foundation for a streamlined onboarding process that fosters long-term partnerships.

Table of Comparison

| Criteria | Supplier Vetting | Supplier Onboarding |

|---|---|---|

| Purpose | Assess supplier credibility and reliability | Integrate approved suppliers into the system |

| Process | Background checks, product quality review, compliance verification | Contract signing, account setup, system training |

| Duration | Short-term evaluation (few days) | Long-term integration (days to weeks) |

| Focus | Risk mitigation and quality control | Smooth operational collaboration |

| Outcome | Approved list of qualified suppliers | Active suppliers fully configured in dropshipping platform |

| Key Tools | Verification software, audits, compliance checklists | Onboarding platforms, training resources, communication channels |

Understanding Supplier Vetting in Dropshipping

Supplier vetting in dropshipping involves thorough evaluation of potential suppliers' reliability, product quality, and shipping efficiency to minimize risks like delays and counterfeit goods. This process includes verifying licenses, reviewing customer feedback, and assessing communication responsiveness to ensure alignment with business standards. Proper supplier vetting enhances operational stability and customer satisfaction, distinguishing it from supplier onboarding, which primarily focuses on contract setup and system integration.

The Essentials of Supplier Onboarding

Supplier onboarding in dropshipping involves a structured process that ensures new suppliers meet quality, compliance, and logistical standards critical for seamless order fulfillment. Key essentials include verifying supplier credentials, integrating their inventory systems with the e-commerce platform, and establishing clear communication channels for order processing and issue resolution. Proper onboarding minimizes risks associated with supply chain disruptions and enhances the overall customer experience by maintaining consistent product availability and delivery timelines.

Key Differences Between Vetting and Onboarding

Supplier vetting in dropshipping involves a thorough evaluation process that assesses a supplier's reliability, product quality, and compliance before establishing a business relationship, focusing on risk mitigation and validation. Supplier onboarding, on the other hand, refers to integrating and setting up the approved supplier into your sales system, including contract agreements, data exchange, and logistics coordination. The key difference lies in vetting being a pre-engagement risk assessment step, whereas onboarding is the operational process that follows supplier approval for seamless collaboration and order fulfillment.

Why Supplier Vetting Matters in Dropshipping

Supplier vetting is crucial in dropshipping to ensure reliability, product quality, and timely order fulfillment, directly impacting customer satisfaction. Thorough vetting identifies trustworthy suppliers with proven track records and reduces risks of delays, counterfeit goods, or communication issues that could harm your brand reputation. Effective supplier vetting streamlines operations and safeguards profitability by preventing costly supply chain disruptions.

Onboarding: Building Successful Supplier Relationships

Supplier onboarding in dropshipping emphasizes establishing clear communication channels, setting expectations for order fulfillment, and integrating supplier systems with your sales platform to ensure seamless operations. Effective onboarding fosters trust, reduces errors, and enhances collaboration, which directly impacts delivery speed and customer satisfaction. Prioritizing thorough onboarding processes leads to stronger supplier partnerships and improved supply chain efficiency.

Criteria for Effective Supplier Vetting

Effective supplier vetting in dropshipping requires thorough evaluation of reliability, product quality, and shipping performance to minimize risks and ensure customer satisfaction. Key criteria include verifying supplier certifications, assessing production capacity, and analyzing past delivery timelines to guarantee consistent order fulfillment. Transparent communication channels and responsive customer service further distinguish sustainable suppliers from unreliable ones.

Steps for a Seamless Supplier Onboarding Process

Effective supplier onboarding in dropshipping begins with thorough supplier vetting through evaluations of product quality, reliability, and compliance with shipping standards. Streamline the onboarding process by clearly communicating expectations, integrating inventory management systems, and providing access to necessary sales and marketing resources. Regular performance monitoring and feedback loops ensure the seamless transition of vetted suppliers into your dropshipping network.

Common Pitfalls in Vetting and Onboarding

Supplier vetting often faces pitfalls such as inadequate background checks, failure to verify product quality, and overlooking compliance with regulations, leading to unreliable partnerships. Supplier onboarding challenges include poor communication of expectations, lack of detailed training on order processing, and insufficient integration of supplier systems with the dropshipping platform. Addressing these issues ensures smoother supply chain management and helps maintain consistent product delivery standards in dropshipping businesses.

Supplier Vetting vs Supplier Onboarding: Which Comes First?

Supplier vetting comes first in the dropshipping process as it involves evaluating potential suppliers for reliability, product quality, and shipping capabilities to ensure a solid partnership. Supplier onboarding follows after vetting and includes integrating the chosen suppliers into your systems, aligning processes, and setting expectations for order fulfillment and communication. Prioritizing thorough supplier vetting minimizes risks and ensures a smoother onboarding experience, ultimately supporting successful dropshipping operations.

Best Practices for Managing Supplier Partnerships

Supplier vetting involves rigorous evaluation of potential suppliers based on criteria such as product quality, reliability, and compliance with industry standards to ensure alignment with business goals. Supplier onboarding emphasizes establishing clear communication channels, setting performance expectations, and integrating suppliers into the operational workflow for seamless collaboration. Best practices for managing supplier partnerships include continuous performance monitoring, fostering transparency, and building long-term relationships to drive mutual growth and efficiency in dropshipping operations.

Supplier vetting vs supplier onboarding Infographic

bizdif.com

bizdif.com