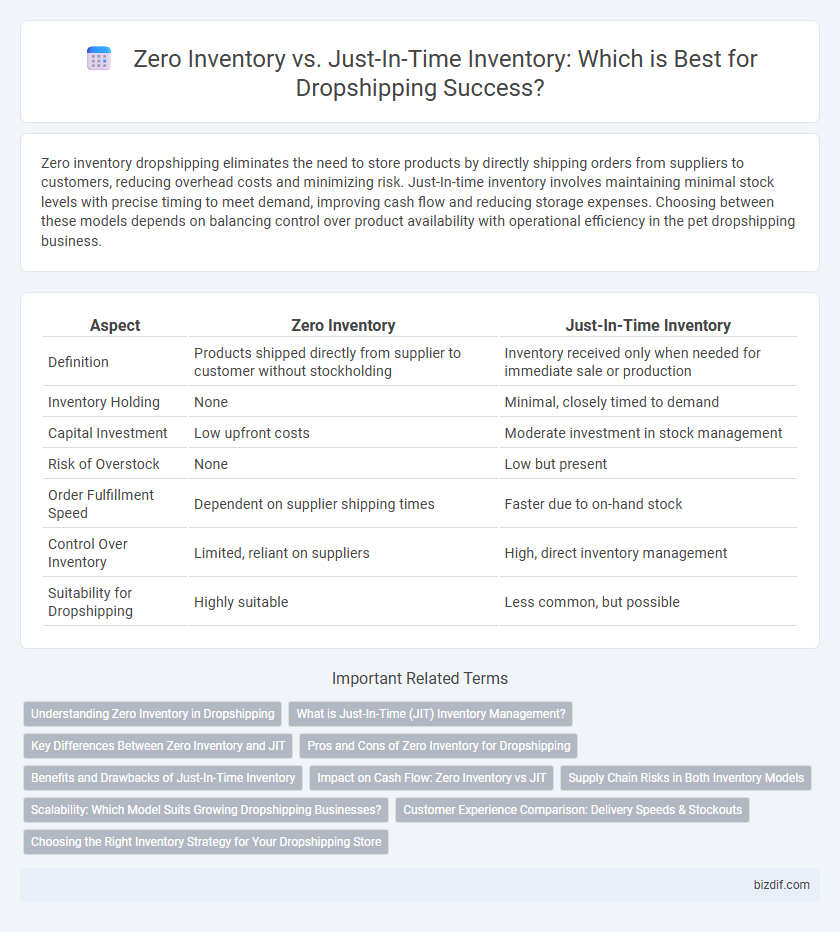

Zero inventory dropshipping eliminates the need to store products by directly shipping orders from suppliers to customers, reducing overhead costs and minimizing risk. Just-In-time inventory involves maintaining minimal stock levels with precise timing to meet demand, improving cash flow and reducing storage expenses. Choosing between these models depends on balancing control over product availability with operational efficiency in the pet dropshipping business.

Table of Comparison

| Aspect | Zero Inventory | Just-In-Time Inventory |

|---|---|---|

| Definition | Products shipped directly from supplier to customer without stockholding | Inventory received only when needed for immediate sale or production |

| Inventory Holding | None | Minimal, closely timed to demand |

| Capital Investment | Low upfront costs | Moderate investment in stock management |

| Risk of Overstock | None | Low but present |

| Order Fulfillment Speed | Dependent on supplier shipping times | Faster due to on-hand stock |

| Control Over Inventory | Limited, reliant on suppliers | High, direct inventory management |

| Suitability for Dropshipping | Highly suitable | Less common, but possible |

Understanding Zero Inventory in Dropshipping

Zero inventory in dropshipping means sellers do not hold physical stock, relying instead on suppliers to fulfill orders directly to customers, minimizing upfront costs and reducing storage risks. This model enhances cash flow efficiency by eliminating the need for inventory purchasing and warehousing, allowing businesses to scale quickly with minimal investment. Understanding zero inventory helps dropshippers optimize supply chain management and improve order fulfillment speed, distinguishing it from Just-In-Time inventory, which requires precise supplier coordination and limited stock holding.

What is Just-In-Time (JIT) Inventory Management?

Just-In-Time (JIT) Inventory Management is a strategy where products are ordered and received only as they are needed in the supply chain, minimizing inventory holding costs. This approach reduces storage expenses and decreases waste by aligning orders closely with demand forecasts, enhancing cash flow efficiency for dropshipping businesses. JIT relies heavily on accurate demand planning and reliable suppliers to ensure timely fulfillment without stockouts.

Key Differences Between Zero Inventory and JIT

Zero inventory in dropshipping means products are shipped directly from suppliers to customers, eliminating the need to hold stock, whereas Just-In-Time (JIT) inventory involves maintaining minimal stock levels by synchronizing orders with production schedules. The key difference lies in inventory ownership and control: zero inventory relies entirely on suppliers for fulfillment, while JIT requires close coordination with manufacturers to reduce storage costs and prevent stockouts. Zero inventory offers greater flexibility with lower upfront investment, but JIT provides more control over product availability and quality assurance.

Pros and Cons of Zero Inventory for Dropshipping

Zero inventory in dropshipping eliminates upfront investment and storage costs by relying on suppliers to hold stock, enabling entrepreneurs to focus on marketing and customer acquisition. This model reduces financial risks and allows for a broad product range, but it also poses challenges such as limited control over inventory accuracy, potential supplier delays, and increased dependency on third-party fulfillment. The trade-off includes less control over order fulfillment times and increased vulnerability to supply chain disruptions compared to just-in-time inventory systems.

Benefits and Drawbacks of Just-In-Time Inventory

Just-In-Time (JIT) inventory minimizes holding costs and reduces waste by receiving goods only as needed for production or sales, making it highly efficient for dropshipping businesses aiming to optimize cash flow. However, reliance on precise supplier timing increases the risk of stockouts and delays, potentially leading to missed sales and customer dissatisfaction. Effective JIT implementation requires robust supplier relationships and accurate demand forecasting to maintain inventory balance and ensure seamless order fulfillment.

Impact on Cash Flow: Zero Inventory vs JIT

Zero Inventory in dropshipping minimizes upfront costs and eliminates storage expenses, significantly improving cash flow by requiring payment only after customer orders are received. Just-In-Time (JIT) inventory reduces holding costs and minimizes waste, but may require more capital tied up in supplier relationships and faster order processing, impacting cash flow stability. Choosing between Zero Inventory and JIT depends on the dropshipping business model's flexibility and ability to manage supplier lead times without risking stockouts or delayed deliveries.

Supply Chain Risks in Both Inventory Models

Zero inventory dropshipping reduces supply chain risks by eliminating the need to hold stock, minimizing financial exposure to unsold products and warehouse costs. Just-In-time inventory models face risks from demand fluctuations and supplier delays, potentially causing stockouts and disrupted order fulfillment. Both models depend heavily on reliable supplier communication and logistics efficiency to maintain seamless operations and customer satisfaction.

Scalability: Which Model Suits Growing Dropshipping Businesses?

Zero inventory dropshipping offers unparalleled scalability by eliminating storage costs and allowing businesses to quickly add new products without physical constraints. Just-in-time inventory improves cash flow and reduces waste but requires precise supplier coordination, which may challenge rapid expansion in dropshipping. Growing dropshipping businesses benefit from zero inventory models due to flexible product range and easier adaptation to fluctuating market demands.

Customer Experience Comparison: Delivery Speeds & Stockouts

Zero inventory dropshipping often results in longer delivery times due to reliance on suppliers' shipping processes, which can negatively impact customer satisfaction. Just-In-Time (JIT) inventory systems balance minimal stock levels with faster order fulfillment, reducing stockouts and improving delivery speed reliability. Customers experience fewer delays and higher product availability with JIT, enhancing overall trust and repeat purchase rates in e-commerce.

Choosing the Right Inventory Strategy for Your Dropshipping Store

Selecting the right inventory strategy for your dropshipping store hinges on balancing cost efficiency and customer satisfaction. Zero inventory minimizes upfront investment and eliminates storage risks by relying on suppliers to ship products directly, while just-in-time inventory improves fulfillment speed and product availability through precise demand forecasting. Analyzing product turnover rates, supplier reliability, and order volume can guide dropshippers to optimize inventory control and boost overall profitability.

Zero Inventory vs Just-In-Time Inventory Infographic

bizdif.com

bizdif.com