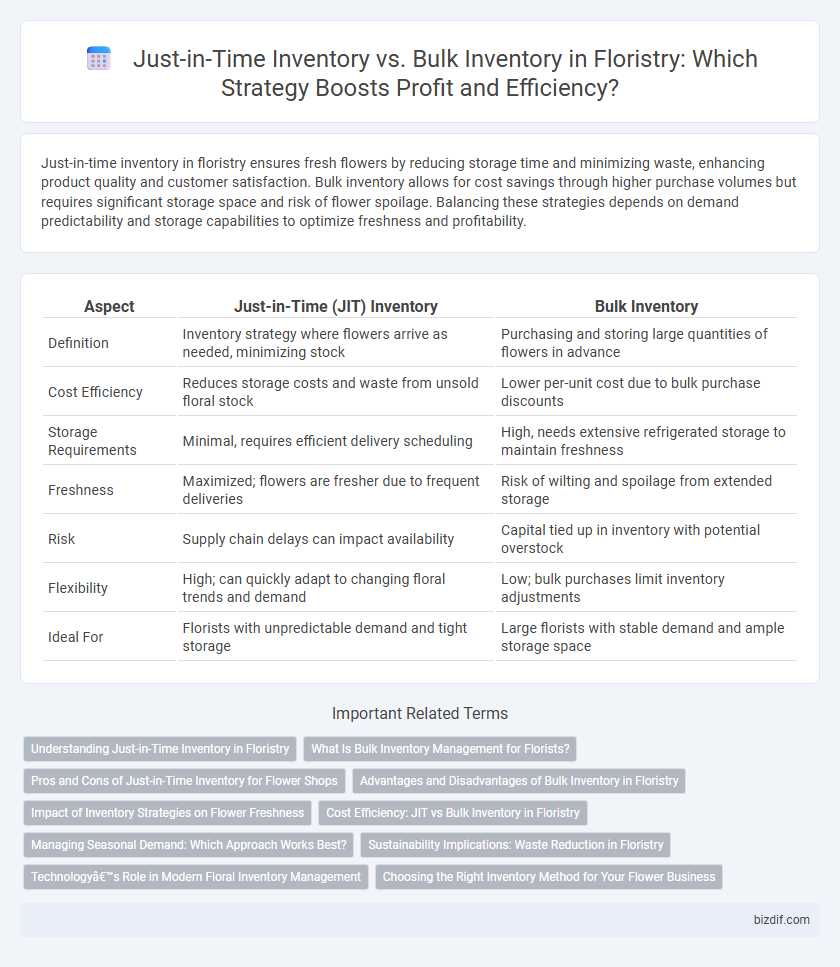

Just-in-time inventory in floristry ensures fresh flowers by reducing storage time and minimizing waste, enhancing product quality and customer satisfaction. Bulk inventory allows for cost savings through higher purchase volumes but requires significant storage space and risk of flower spoilage. Balancing these strategies depends on demand predictability and storage capabilities to optimize freshness and profitability.

Table of Comparison

| Aspect | Just-in-Time (JIT) Inventory | Bulk Inventory |

|---|---|---|

| Definition | Inventory strategy where flowers arrive as needed, minimizing stock | Purchasing and storing large quantities of flowers in advance |

| Cost Efficiency | Reduces storage costs and waste from unsold floral stock | Lower per-unit cost due to bulk purchase discounts |

| Storage Requirements | Minimal, requires efficient delivery scheduling | High, needs extensive refrigerated storage to maintain freshness |

| Freshness | Maximized; flowers are fresher due to frequent deliveries | Risk of wilting and spoilage from extended storage |

| Risk | Supply chain delays can impact availability | Capital tied up in inventory with potential overstock |

| Flexibility | High; can quickly adapt to changing floral trends and demand | Low; bulk purchases limit inventory adjustments |

| Ideal For | Florists with unpredictable demand and tight storage | Large florists with stable demand and ample storage space |

Understanding Just-in-Time Inventory in Floristry

Just-in-time (JIT) inventory in floristry minimizes flower waste by aligning fresh flower deliveries closely with demand, ensuring blooms are at peak freshness upon arrangement. This approach reduces storage costs and the risk of oversupply common in bulk inventory systems, which often necessitate extensive refrigeration and can lead to significant spoilage. Florists leveraging JIT inventory benefit from improved cash flow and increased customer satisfaction through consistently high-quality floral products.

What Is Bulk Inventory Management for Florists?

Bulk inventory management for florists involves purchasing and storing large quantities of flowers and supplies to ensure consistent availability and potentially lower per-unit costs. This approach requires efficient storage solutions like climate-controlled environments to maintain flower freshness over longer periods. Managing bulk inventory helps florists meet high demand during peak seasons but risks increased waste if inventory is not sold promptly.

Pros and Cons of Just-in-Time Inventory for Flower Shops

Just-in-time (JIT) inventory in flower shops minimizes waste by ensuring fresh flower arrivals match immediate demand, reducing spoilage and storage costs. However, JIT requires precise coordination with suppliers and poses risks of stockouts during supply chain disruptions, potentially impacting customer satisfaction. This method benefits shops prioritizing freshness and lower holding costs but demands robust forecasting and reliable delivery systems.

Advantages and Disadvantages of Bulk Inventory in Floristry

Bulk inventory in floristry offers the advantage of cost savings through wholesale purchasing and ensures flower availability during peak demand periods, reducing the risk of stockouts. However, bulk buying increases the risk of spoilage due to the perishable nature of flowers, leading to potential waste and higher storage costs. Managing large quantities requires adequate refrigeration and space, complicating inventory control and potentially impacting overall profitability.

Impact of Inventory Strategies on Flower Freshness

Just-in-time inventory minimizes storage time, ensuring flowers arrive fresh and vibrant, reducing spoilage and waste in floristry. Bulk inventory can lower costs through economies of scale but risks prolonged storage leading to diminished flower freshness and quality. Effective inventory strategies balance order frequency and volume to optimize flower longevity and customer satisfaction.

Cost Efficiency: JIT vs Bulk Inventory in Floristry

Just-in-time inventory in floristry minimizes holding costs by receiving fresh flowers as needed, reducing waste from perishables and lowering refrigeration expenses. Bulk inventory can lower per-unit purchase prices through volume discounts but increases storage costs and risk of spoilage, impacting overall cost efficiency. Effective inventory management balances the freshness and availability of floral products with operational expenses to optimize profitability.

Managing Seasonal Demand: Which Approach Works Best?

Just-in-time inventory in floristry minimizes waste and ensures fresh stock by aligning flower deliveries with peak seasonal demand, enhancing cash flow and reducing storage costs. Bulk inventory suits florists with stable demand patterns, allowing bulk purchasing discounts but risking overstocking and spoilage during off-peak seasons. Managing seasonal demand effectively requires balancing just-in-time agility with bulk inventory security based on market volatility and storage capabilities.

Sustainability Implications: Waste Reduction in Floristry

Just-in-time inventory in floristry significantly reduces waste by aligning flower orders with real-time demand, minimizing the risk of unsold blooms that contribute to landfill. Bulk inventory, while cost-effective, often leads to overstocking and the disposal of perishable floral products, increasing environmental footprint through resource waste and decomposition emissions. Sustainable floristry practices increasingly favor just-in-time strategies to enhance inventory efficiency and promote ecological responsibility by lowering excess flower waste.

Technology’s Role in Modern Floral Inventory Management

Technology-driven floral inventory management leverages real-time data analytics and IoT sensors to optimize just-in-time inventory, reducing waste and ensuring freshness. Automated forecasting systems analyze sales trends and seasonal demand to balance stock levels, minimizing excess bulk inventory costs. Advanced software platforms integrate supplier networks for seamless ordering, enhancing efficiency and customer satisfaction in floristry businesses.

Choosing the Right Inventory Method for Your Flower Business

Just-in-time inventory minimizes waste and storage costs by receiving flowers as orders are placed, ideal for businesses with high turnover and limited space. Bulk inventory offers cost savings through volume purchasing and ensures flower availability during peak seasons but requires substantial refrigeration and risk management to prevent spoilage. Selecting the right inventory method depends on factors such as order volume, storage capacity, cash flow, and seasonal demand in the floristry industry.

Just-in-time inventory vs bulk inventory Infographic

bizdif.com

bizdif.com