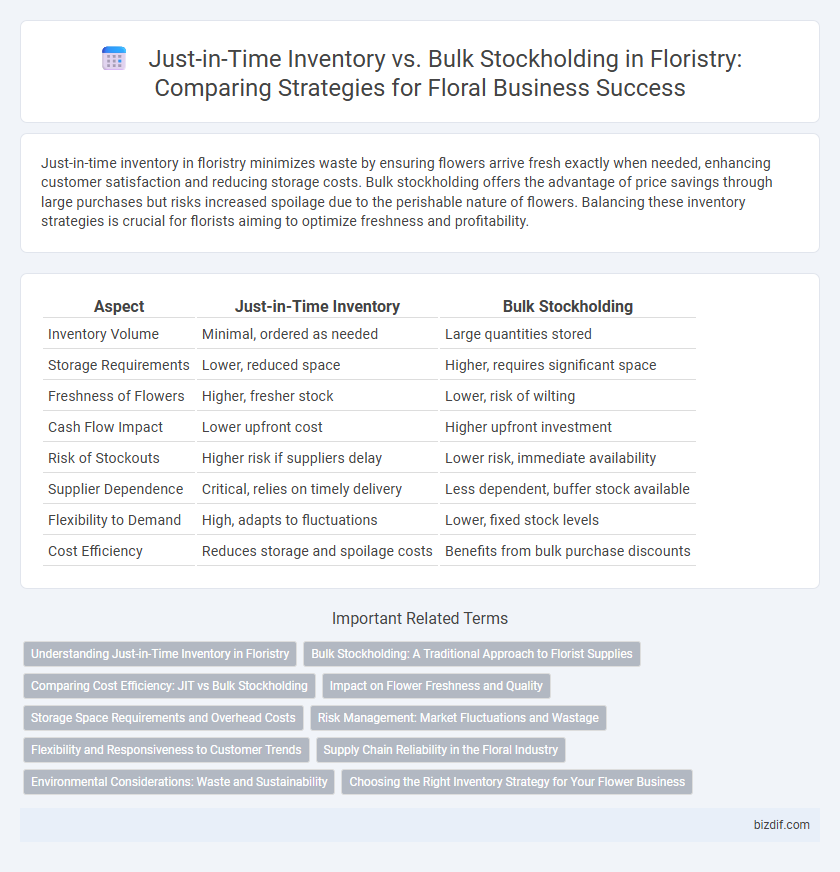

Just-in-time inventory in floristry minimizes waste by ensuring flowers arrive fresh exactly when needed, enhancing customer satisfaction and reducing storage costs. Bulk stockholding offers the advantage of price savings through large purchases but risks increased spoilage due to the perishable nature of flowers. Balancing these inventory strategies is crucial for florists aiming to optimize freshness and profitability.

Table of Comparison

| Aspect | Just-in-Time Inventory | Bulk Stockholding |

|---|---|---|

| Inventory Volume | Minimal, ordered as needed | Large quantities stored |

| Storage Requirements | Lower, reduced space | Higher, requires significant space |

| Freshness of Flowers | Higher, fresher stock | Lower, risk of wilting |

| Cash Flow Impact | Lower upfront cost | Higher upfront investment |

| Risk of Stockouts | Higher risk if suppliers delay | Lower risk, immediate availability |

| Supplier Dependence | Critical, relies on timely delivery | Less dependent, buffer stock available |

| Flexibility to Demand | High, adapts to fluctuations | Lower, fixed stock levels |

| Cost Efficiency | Reduces storage and spoilage costs | Benefits from bulk purchase discounts |

Understanding Just-in-Time Inventory in Floristry

Just-in-time (JIT) inventory in floristry minimizes waste by synchronizing flower deliveries with customer demand, ensuring blooms arrive fresh for immediate use. This approach reduces storage costs and spoilage compared to bulk stockholding, where large quantities risk wilting before sale. Implementing JIT requires precise demand forecasting and strong supplier relationships to maintain continuous floral availability.

Bulk Stockholding: A Traditional Approach to Florist Supplies

Bulk stockholding remains a traditional approach in floristry, offering florists immediate access to a wide range of fresh flowers and supplies essential for daily arrangements. Maintaining extensive inventory helps avoid delays associated with supplier lead times, ensuring readiness for peak demand periods such as holidays and events. Although this method requires significant storage space and precise climate controls to preserve flower longevity, it provides stability and consistent availability critical to successful floral operations.

Comparing Cost Efficiency: JIT vs Bulk Stockholding

Just-in-time (JIT) inventory in floristry reduces holding costs by minimizing excess stock and waste, optimizing cash flow compared to bulk stockholding, which requires significant capital tied up in large flower inventories and storage expenses. Bulk stockholding benefits from volume discounts and preparedness for demand surges but risks losses from perishable flowers and storage deterioration, increasing overall costs. Florists must weigh the cost efficiencies of JIT's lean inventory model against bulk stockholding's economies of scale and potential spoilage to determine the optimal stocking strategy.

Impact on Flower Freshness and Quality

Just-in-time inventory in floristry ensures flowers are delivered closer to their bloom peak, significantly enhancing freshness and quality compared to bulk stockholding, which increases the risk of wilting and deterioration due to prolonged storage. Bulk stockholding may reduce purchase costs but often leads to higher waste and compromised aesthetics, affecting customer satisfaction. Prioritizing just-in-time deliveries supports optimal floral condition, extending vase life and preserving vibrant colors essential for premium floral arrangements.

Storage Space Requirements and Overhead Costs

Just-in-time inventory in floristry minimizes storage space requirements by receiving flowers only as needed, reducing overhead costs associated with refrigeration and preservation. Bulk stockholding demands larger storage facilities to accommodate high volumes of perishable flowers, increasing expenses for climate control and inventory management. Efficient inventory strategies balance freshness with space utilization and cost efficiency to optimize floral product quality and profitability.

Risk Management: Market Fluctuations and Wastage

Just-in-time inventory in floristry minimizes risk by reducing excess stock that can wilt or become unsellable due to market fluctuations and changing customer preferences. Bulk stockholding increases exposure to wastage as flowers have a limited shelf life, leading to potential financial losses if demand decreases unexpectedly. Effective risk management balances timely procurement with adequate stock levels to optimize freshness and reduce spoilage costs.

Flexibility and Responsiveness to Customer Trends

Just-in-time inventory in floristry enhances flexibility by allowing shops to quickly adjust flower orders based on emerging customer trends and seasonal demand, minimizing waste and ensuring freshness. Bulk stockholding supports responsiveness by maintaining a ready supply of popular blooms, reducing lead times for fulfilling large orders or sudden spikes in demand. Balancing these approaches enables florists to remain agile, meeting diverse customer preferences while optimizing inventory costs.

Supply Chain Reliability in the Floral Industry

Just-in-time inventory enhances supply chain reliability in the floral industry by reducing waste and ensuring fresher stock through precise delivery schedules aligned with demand forecasts. Bulk stockholding provides a buffer against supply chain disruptions but increases the risk of floral spoilage and storage costs due to the perishable nature of flowers. Optimizing supply chain reliability requires balancing just-in-time practices with strategic bulk reserves to maintain flower freshness and meet fluctuating market demands efficiently.

Environmental Considerations: Waste and Sustainability

Just-in-time inventory in floristry minimizes waste by reducing overstock and the need for excess refrigeration, supporting sustainability through lower energy consumption and decreased floral spoilage. Bulk stockholding often leads to higher waste due to unsold flowers wilting, increasing landfill contributions and resource inefficiencies. Emphasizing just-in-time systems promotes eco-friendly practices by aligning supply closely with demand, reducing environmental impact in flower shops.

Choosing the Right Inventory Strategy for Your Flower Business

Just-in-time inventory minimizes holding costs and reduces flower waste by receiving blooms only as needed, ensuring freshness for customers and optimizing cash flow. Bulk stockholding secures better pricing through volume discounts and guarantees availability during peak seasons but requires adequate storage and careful demand forecasting to avoid spoilage. Selecting the right inventory strategy depends on business size, sales volume, supply chain reliability, and seasonal demand patterns in the flower market.

Just-in-time inventory vs bulk stockholding Infographic

bizdif.com

bizdif.com