Assembly line gift basket creation for pets ensures efficiency and consistency by producing pre-designed sets with standardized items, perfect for bulk orders or retail settings. Custom assembly offers personalized gift baskets tailored to individual pet preferences, allowing for unique combinations of toys, treats, and accessories that cater to specific pet needs. Choosing between assembly line and custom assembly depends on the desired balance between speed and personalization in pet gift basket production.

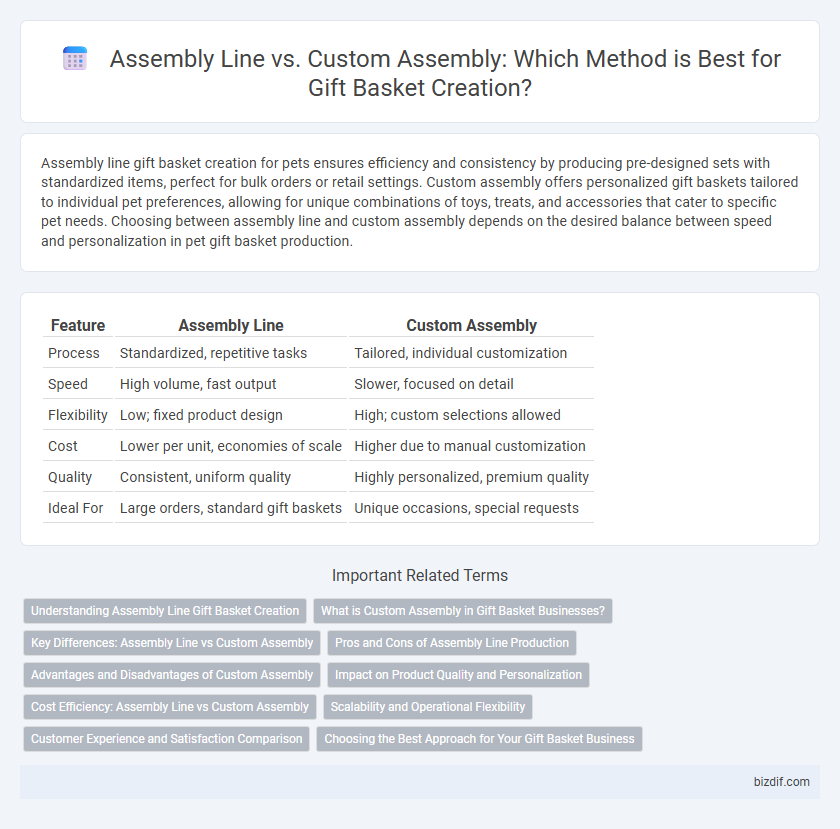

Table of Comparison

| Feature | Assembly Line | Custom Assembly |

|---|---|---|

| Process | Standardized, repetitive tasks | Tailored, individual customization |

| Speed | High volume, fast output | Slower, focused on detail |

| Flexibility | Low; fixed product design | High; custom selections allowed |

| Cost | Lower per unit, economies of scale | Higher due to manual customization |

| Quality | Consistent, uniform quality | Highly personalized, premium quality |

| Ideal For | Large orders, standard gift baskets | Unique occasions, special requests |

Understanding Assembly Line Gift Basket Creation

Assembly line gift basket creation streamlines production by using standardized components and repetitive tasks, enabling higher efficiency and consistent quality. This method reduces assembly time and labor costs through predefined templates and bulk sourcing of popular items. Understanding assembly line techniques helps businesses scale operations while maintaining product uniformity and meeting large order demands.

What is Custom Assembly in Gift Basket Businesses?

Custom assembly in gift basket businesses involves handpicking and arranging items based on individual customer preferences, creating personalized and unique gift baskets. This process allows for tailored selections of products such as gourmet foods, wines, or specialty items, enhancing customer satisfaction and differentiation from mass-produced baskets. Custom assembly emphasizes creativity and attention to detail, often resulting in higher perceived value and brand loyalty.

Key Differences: Assembly Line vs Custom Assembly

Assembly line gift basket creation emphasizes efficiency and uniformity, producing large quantities with consistent designs and standardized components. Custom assembly prioritizes personalization, allowing unique combinations and tailor-made selections to meet specific customer preferences or occasions. Key differences lie in production speed, flexibility, and level of customization, with assembly lines favoring mass production and custom assembly catering to individualization.

Pros and Cons of Assembly Line Production

Assembly line production in gift basket creation offers high efficiency and consistent quality by standardizing processes, reducing production time, and lowering labor costs. However, it limits customization options, potentially reducing customer satisfaction for personalized orders and increasing inventory requirements for pre-made components. This method suits large-scale operations aiming for volume but struggles with flexibility in accommodating unique or seasonal product variations.

Advantages and Disadvantages of Custom Assembly

Custom assembly offers personalized gift baskets tailored to individual preferences, enhancing customer satisfaction and perceived value. This approach allows for flexibility in selecting unique items, but it tends to increase production time and labor costs compared to standardized assembly lines. The trade-off between customization and efficiency can impact overall scalability and pricing strategies.

Impact on Product Quality and Personalization

Assembly line gift basket creation ensures consistent product quality through standardized processes but limits personalization options. Custom assembly enhances personalization by tailoring each basket to specific preferences, often resulting in higher perceived value despite longer production times. Balancing assembly line efficiency with custom assembly flexibility can optimize both product quality and personalized customer experience.

Cost Efficiency: Assembly Line vs Custom Assembly

Assembly line gift basket creation significantly reduces labor costs and production time by standardizing components and processes, enabling economies of scale. Custom assembly incurs higher expenses due to individualized selection and handling, increasing both material and labor costs. Businesses prioritizing cost efficiency benefit from assembly lines, while custom assembly suits niche markets willing to pay premium prices for personalized products.

Scalability and Operational Flexibility

Assembly line gift basket creation offers high scalability by streamlining repetitive tasks, allowing for rapid production of large volumes with consistent quality. Custom assembly provides greater operational flexibility by enabling tailored designs and personalized selections, but may face challenges in efficiently scaling due to varied components and manual labor requirements. Balancing scalability and flexibility depends on business goals, with assembly lines suited for mass production and custom assembly ideal for specialized, niche markets.

Customer Experience and Satisfaction Comparison

Assembly line gift basket creation offers consistent quality and faster delivery, enhancing customer satisfaction through reliable order fulfillment and standardization. Custom assembly provides personalized experiences by tailoring baskets to individual preferences, boosting customer engagement and creating emotional value. Balancing efficiency from assembly lines with personalization in custom assembly maximizes overall customer experience and satisfaction.

Choosing the Best Approach for Your Gift Basket Business

Assembly line production enables faster, cost-effective gift basket creation by standardizing components and processes, ideal for high-volume orders. Custom assembly offers personalized, unique baskets tailored to individual customer preferences, enhancing brand differentiation and customer satisfaction. Selecting the best approach depends on your business model, order volume, and the desired balance between efficiency and personalization.

Assembly line vs Custom assembly Infographic

bizdif.com

bizdif.com