Hand-assembly of pet gift baskets ensures meticulous attention to detail and personalized customization, enhancing the overall quality and uniqueness of each basket. Automated assembly increases production speed and consistency but may lack the careful selection and arrangement that cater to individual pet owners' preferences. Choosing hand-assembly supports artisanal craftsmanship, while automated processes excel in meeting high-volume demand efficiently.

Table of Comparison

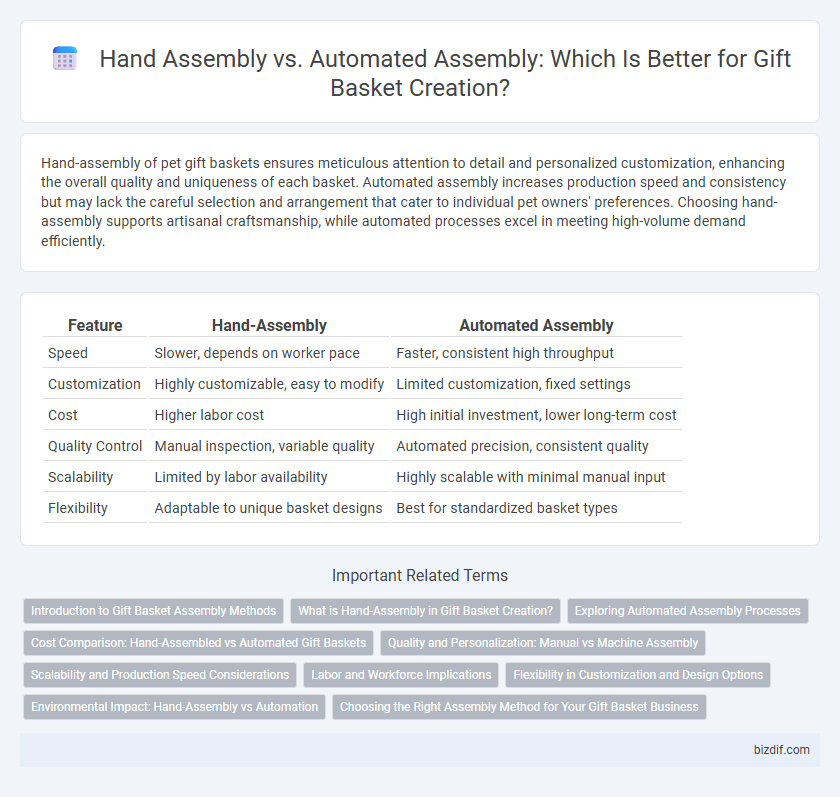

| Feature | Hand-Assembly | Automated Assembly |

|---|---|---|

| Speed | Slower, depends on worker pace | Faster, consistent high throughput |

| Customization | Highly customizable, easy to modify | Limited customization, fixed settings |

| Cost | Higher labor cost | High initial investment, lower long-term cost |

| Quality Control | Manual inspection, variable quality | Automated precision, consistent quality |

| Scalability | Limited by labor availability | Highly scalable with minimal manual input |

| Flexibility | Adaptable to unique basket designs | Best for standardized basket types |

Introduction to Gift Basket Assembly Methods

Gift basket assembly methods include hand-assembly, which offers precision and customization by allowing artisans to carefully select and arrange items, enhancing the personal touch and quality control. Automated assembly uses machinery to streamline production, increasing efficiency and consistency for larger-scale operations. Choosing between these methods depends on balancing craftsmanship with volume demands and production speed.

What is Hand-Assembly in Gift Basket Creation?

Hand-assembly in gift basket creation involves manually selecting, arranging, and packaging each item to ensure personalized detail and quality control. Skilled artisans carefully place products to achieve an aesthetically pleasing presentation that reflects customization and thoughtful design. This method allows for greater flexibility in incorporating unique or delicate items that automated processes may mishandle.

Exploring Automated Assembly Processes

Automated assembly processes in gift basket creation enhance efficiency by using robotics and conveyor systems to precisely place items, significantly reducing labor costs and production time. Advanced vision systems and AI-powered sorting enable customization at scale, ensuring consistent quality and minimizing errors. Integration with inventory management software streamlines material handling and allows real-time adjustments to order specifications.

Cost Comparison: Hand-Assembled vs Automated Gift Baskets

Hand-assembled gift baskets typically incur higher labor costs due to the time-intensive manual process, impacting overall price points significantly. Automated assembly leverages machinery to reduce labor expenses, increasing production speed and consistency while lowering per-unit costs. Businesses must evaluate volume, customization needs, and budget constraints to determine the most cost-effective assembly method.

Quality and Personalization: Manual vs Machine Assembly

Hand-assembly in gift basket creation ensures superior quality control and personalized touches that machines struggle to replicate, resulting in unique, custom arrangements tailored to individual preferences. Automated assembly provides speed and consistency but often lacks the nuanced craftsmanship and attention to detail that define premium gift baskets. Balancing manual craftsmanship with selective automation optimizes overall quality while maintaining personalization.

Scalability and Production Speed Considerations

Hand-assembly offers meticulous customization and quality control but limits scalability and production speed due to its labor-intensive nature. Automated assembly significantly accelerates production rates and enables large-scale output with consistent quality, making it ideal for meeting high demand. Choosing between methods depends on balancing personalized craftsmanship against the need for rapid, uniform gift basket production.

Labor and Workforce Implications

Hand-assembly in gift basket creation demands skilled labor and offers greater customization, impacting workforce size and training needs. Automated assembly reduces manual labor, increases production speed, and lowers labor costs, but may require investment in machinery and technical staff. Workforce implications include potential job displacement balanced by opportunities for upskilling in automation management.

Flexibility in Customization and Design Options

Hand-assembly in gift basket creation allows for greater flexibility in customization, enabling personalized selection, arrangement, and unique design elements tailored to individual preferences. Automated assembly offers efficient production but typically limits design options to predefined templates and standardized configurations. The choice between hand and automated assembly depends on balancing the need for bespoke creativity against volume and consistency requirements.

Environmental Impact: Hand-Assembly vs Automation

Hand-assembly of gift baskets often results in lower energy consumption and reduced carbon emissions compared to automated assembly lines that rely heavily on electricity and machinery. Manual processes produce less electronic waste and allow for more sustainable sourcing and quality control of materials, minimizing environmental footprints. Automation, while efficient, frequently involves significant resource use and generates higher waste, making hand-assembly a more eco-friendly choice in gift basket creation.

Choosing the Right Assembly Method for Your Gift Basket Business

Hand-assembly of gift baskets offers personalized customization and attention to detail, ideal for small-scale or luxury markets prioritizing quality and unique presentation. Automated assembly increases production speed and consistency, making it suitable for high-volume businesses aiming to reduce labor costs and meet large order demands. Selecting the appropriate method depends on your business scale, target market, and balance between customization and efficiency to optimize profitability and customer satisfaction.

Hand-Assembly vs Automated Assembly Infographic

bizdif.com

bizdif.com