In-house assembly of pet gift baskets allows for greater quality control and customization, ensuring each item meets brand standards and customer expectations. Outsourced assembly can reduce labor costs and increase production speed, but it may sacrifice attention to detail and consistency. Choosing between in-house and outsourced assembly depends on balancing cost efficiency with the need for personalized, high-quality gift baskets.

Table of Comparison

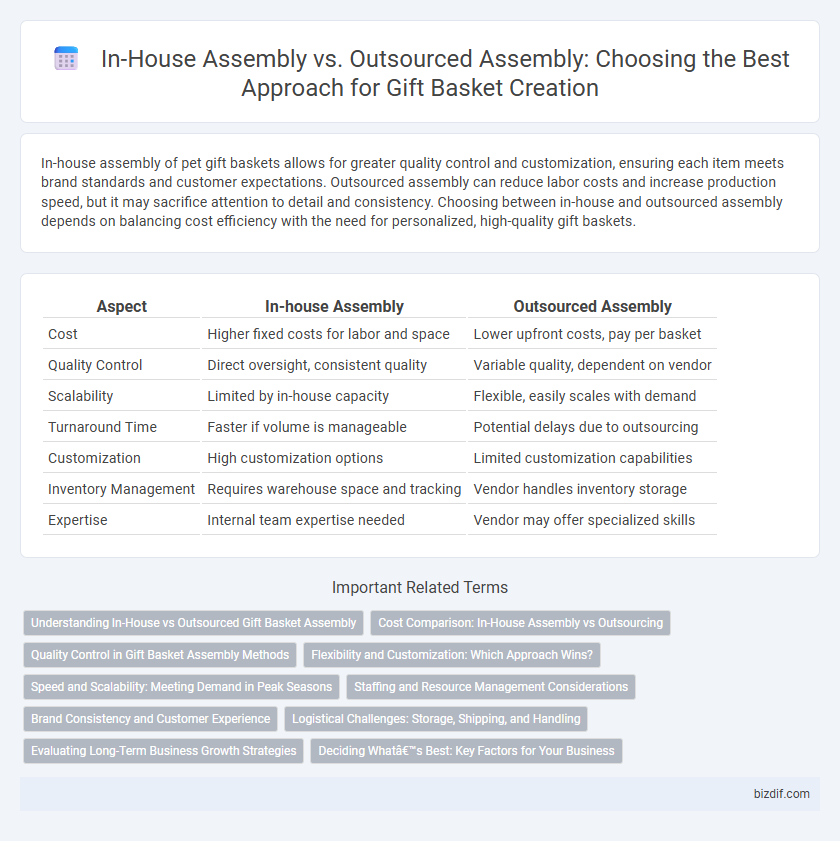

| Aspect | In-house Assembly | Outsourced Assembly |

|---|---|---|

| Cost | Higher fixed costs for labor and space | Lower upfront costs, pay per basket |

| Quality Control | Direct oversight, consistent quality | Variable quality, dependent on vendor |

| Scalability | Limited by in-house capacity | Flexible, easily scales with demand |

| Turnaround Time | Faster if volume is manageable | Potential delays due to outsourcing |

| Customization | High customization options | Limited customization capabilities |

| Inventory Management | Requires warehouse space and tracking | Vendor handles inventory storage |

| Expertise | Internal team expertise needed | Vendor may offer specialized skills |

Understanding In-House vs Outsourced Gift Basket Assembly

In-house gift basket assembly offers greater control over customization, quality, and timelines, allowing businesses to ensure each basket meets specific brand standards. Outsourced assembly can reduce labor costs and operational complexity by leveraging specialized providers with established workflows and economies of scale. Evaluating factors such as production volume, budget constraints, and desired customization level is essential to determine the optimal assembly approach for efficient and scalable gift basket creation.

Cost Comparison: In-House Assembly vs Outsourcing

In-house assembly typically incurs higher fixed costs due to labor, equipment, and facility expenses but allows greater control over quality and customization. Outsourced assembly often reduces direct labor costs and capital investment by leveraging specialized vendors, offering scalability and lower overhead. Evaluating cost efficiency involves analyzing volume requirements, production complexity, and long-term financial impacts on gift basket creation.

Quality Control in Gift Basket Assembly Methods

In-house gift basket assembly enables direct supervision and consistent quality control, ensuring each component meets brand standards. Outsourced assembly risks variability in craftsmanship, requiring rigorous vendor vetting and regular inspections to maintain product quality. Maintaining stringent quality control protocols is essential to deliver flawless, customer-ready gift baskets regardless of the assembly method.

Flexibility and Customization: Which Approach Wins?

In-house gift basket assembly offers unparalleled flexibility and customization, enabling companies to tailor products to specific customer preferences with immediate adjustments. Outsourced assembly may limit personalization options due to standardized processes and longer turnaround times. Businesses prioritizing unique, customizable gift baskets benefit most from maintaining control through in-house assembly.

Speed and Scalability: Meeting Demand in Peak Seasons

In-house assembly offers greater control and customization, enabling faster turnaround times during peak seasons through direct management of workflow and staff allocation. Outsourced assembly provides scalability advantages, allowing businesses to quickly ramp up production without the constraints of internal capacity limits. Balancing these options ensures efficient fulfillment of high-volume orders while maintaining quality and meeting fluctuating seasonal demand.

Staffing and Resource Management Considerations

In-house assembly of gift baskets requires dedicated staffing, which involves recruiting, training, and managing a skilled team to maintain quality and efficiency, impacting labor costs and scheduling flexibility. Outsourced assembly leverages external vendors with specialized resources and expertise, reducing internal staffing burdens and allowing focus on core business functions while potentially increasing control challenges and vendor dependency. Effective resource management balances these factors to optimize production timelines, maintain quality standards, and control operational expenses.

Brand Consistency and Customer Experience

In-house assembly of gift baskets ensures strict brand consistency by maintaining control over every detail, allowing for personalized touches that reflect company values and quality standards. Outsourced assembly may introduce variability in design and packaging, potentially diluting brand identity and impacting customer experience negatively. Consistent branding through in-house assembly enhances customer satisfaction by delivering a cohesive, high-quality product that aligns with brand promises.

Logistical Challenges: Storage, Shipping, and Handling

In-house assembly of gift baskets allows for direct oversight of storage conditions, ensuring product quality and reducing damage risk during handling. Outsourced assembly often requires coordination with third-party warehouses, complicating inventory management and increasing shipping costs due to fragmented logistics. Managing reverse logistics and customs clearance for international shipments further intensifies challenges when outsourcing assembly operations.

Evaluating Long-Term Business Growth Strategies

In-house assembly of gift baskets offers greater control over quality, customization, and brand consistency, which can strengthen customer loyalty and support sustainable growth. Outsourced assembly reduces labor costs and scales production quickly but may risk variability in quality and longer turnaround times, impacting brand reputation. Evaluating these factors in relation to business goals, cost structures, and market demand is crucial for optimizing long-term growth strategies.

Deciding What’s Best: Key Factors for Your Business

Evaluating in-house versus outsourced gift basket assembly centers on factors like cost efficiency, quality control, and scalability. In-house assembly allows for tighter customization and direct oversight, while outsourcing can reduce labor expenses and accommodate fluctuating order volumes. Businesses must analyze production capacity, budget constraints, and desired product consistency to determine the optimal assembly method.

In-house assembly vs outsourced assembly Infographic

bizdif.com

bizdif.com