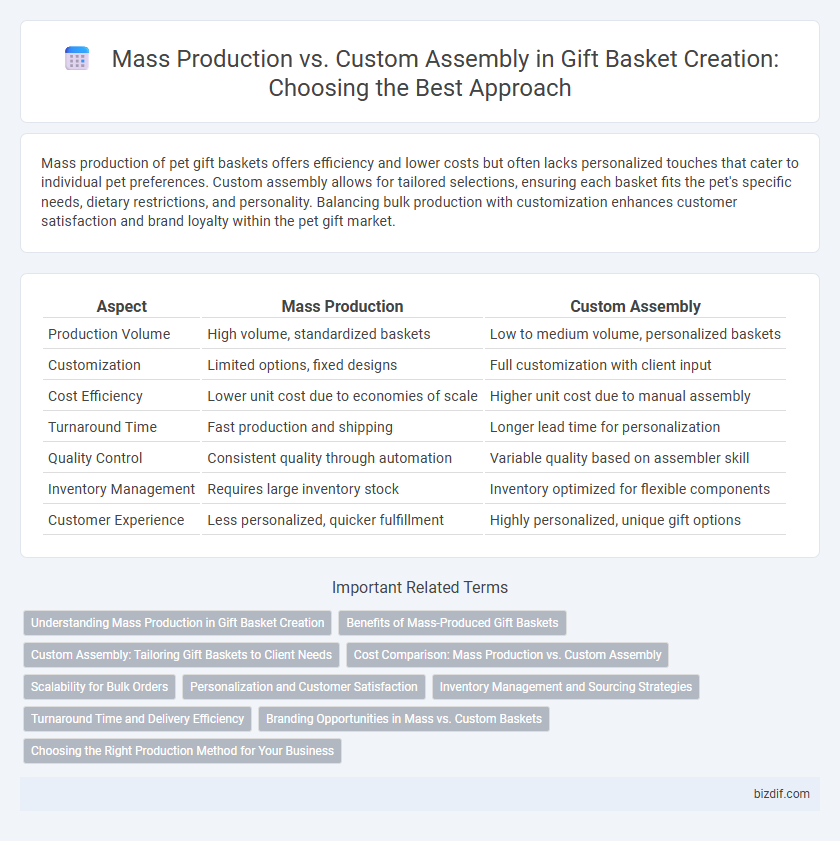

Mass production of pet gift baskets offers efficiency and lower costs but often lacks personalized touches that cater to individual pet preferences. Custom assembly allows for tailored selections, ensuring each basket fits the pet's specific needs, dietary restrictions, and personality. Balancing bulk production with customization enhances customer satisfaction and brand loyalty within the pet gift market.

Table of Comparison

| Aspect | Mass Production | Custom Assembly |

|---|---|---|

| Production Volume | High volume, standardized baskets | Low to medium volume, personalized baskets |

| Customization | Limited options, fixed designs | Full customization with client input |

| Cost Efficiency | Lower unit cost due to economies of scale | Higher unit cost due to manual assembly |

| Turnaround Time | Fast production and shipping | Longer lead time for personalization |

| Quality Control | Consistent quality through automation | Variable quality based on assembler skill |

| Inventory Management | Requires large inventory stock | Inventory optimized for flexible components |

| Customer Experience | Less personalized, quicker fulfillment | Highly personalized, unique gift options |

Understanding Mass Production in Gift Basket Creation

Mass production in gift basket creation involves producing large quantities of identical baskets efficiently by utilizing standardized materials and assembly-line techniques. This approach significantly reduces unit costs and turnaround times, making it ideal for bulk orders and retail distribution. Consistency in design and quality control are central to maintaining brand reputation and customer satisfaction during mass production.

Benefits of Mass-Produced Gift Baskets

Mass-produced gift baskets offer consistent quality and quicker turnaround times, making them ideal for large-scale orders and corporate gifting. Standardized packaging and pre-selected contents reduce production costs, resulting in more affordable pricing for bulk purchases. Automated assembly lines ensure uniform presentation, enhancing brand recognition and customer satisfaction through reliable product delivery.

Custom Assembly: Tailoring Gift Baskets to Client Needs

Custom assembly in gift basket creation allows for precise tailoring to client specifications, enhancing personalization and customer satisfaction. Unlike mass production, which standardizes contents, custom assembly incorporates unique items and branding elements aligned with client preferences. This approach supports niche markets and fosters stronger client relationships by delivering highly relevant and memorable gift experiences.

Cost Comparison: Mass Production vs. Custom Assembly

Mass production of gift baskets significantly lowers per-unit costs due to bulk purchasing of materials and streamlined assembly line processes, reducing labor expenses. Custom assembly incurs higher costs by requiring individualized selection of items and more labor-intensive packaging, which increases production time and material waste. Businesses must weigh lower costs and faster output of mass production against the personalized value and premium pricing opportunities of custom gift baskets.

Scalability for Bulk Orders

Mass production of gift baskets offers unparalleled scalability for bulk orders by streamlining assembly processes and reducing per-unit costs through automation and standardized components. Custom assembly, while allowing for personalized touches and unique product combinations, often faces limitations in speed and resource allocation, making it less efficient for large-scale demands. Businesses need to balance the need for customization with production capacity to optimize delivery timelines and cost-effectiveness in bulk gifting solutions.

Personalization and Customer Satisfaction

Mass production of gift baskets offers efficiency and lower costs but often lacks the personalized touch that enhances customer satisfaction. Custom assembly allows for tailored selections based on individual preferences, increasing perceived value and emotional connection. Prioritizing personalization in gift basket creation leads to higher customer retention and positive brand reputation.

Inventory Management and Sourcing Strategies

Mass production of gift baskets enables streamlined inventory management by minimizing component variety, reducing storage complexity, and facilitating bulk sourcing agreements with suppliers to lower costs. Custom assembly requires dynamic inventory tracking systems to handle diverse product variants and more frequent replenishment cycles, demanding agile sourcing strategies that prioritize supplier flexibility and rapid delivery. Effective balance between these approaches hinges on optimizing stock levels and supplier relationships to meet demand variability without incurring excess holding costs.

Turnaround Time and Delivery Efficiency

Mass production in gift basket creation offers significantly faster turnaround times due to standardized processes and bulk purchasing, ensuring consistent delivery schedules. Custom assembly, while allowing personalized and unique gift combinations, generally requires longer preparation times and can result in variable delivery efficiency depending on order complexity. Businesses seeking rapid fulfillment and streamlined logistics often prefer mass production, whereas those prioritizing bespoke experiences accept extended timelines.

Branding Opportunities in Mass vs. Custom Baskets

Mass production of gift baskets offers consistent branding opportunities through uniform packaging and standardized logos, enhancing brand recognition across large distributions. Custom assembly allows for personalized branding, tailoring each basket's design and contents to specific customer demographics, which can deepen brand loyalty and create unique customer experiences. Balancing these approaches can maximize visibility while maintaining a connection to target audiences through differentiated branding strategies.

Choosing the Right Production Method for Your Business

Mass production streamlines gift basket creation through standardized designs and bulk purchasing, reducing costs and ensuring consistent quality for large orders. Custom assembly offers flexibility to tailor each basket to specific customer preferences, enhancing personalization and brand differentiation. Selecting the ideal method depends on business scale, budget constraints, and customer demand for uniqueness versus volume efficiency.

Mass production vs Custom assembly Infographic

bizdif.com

bizdif.com