Automated meal assembly for pets offers consistent portion control and saves time compared to manual meal prepping, reducing human error and ensuring nutritional accuracy. While manual prepping allows for customization based on individual pet preferences and dietary restrictions, it is often labor-intensive and less efficient. Integrating automation enhances convenience and scalability in providing balanced meals for pets.

Table of Comparison

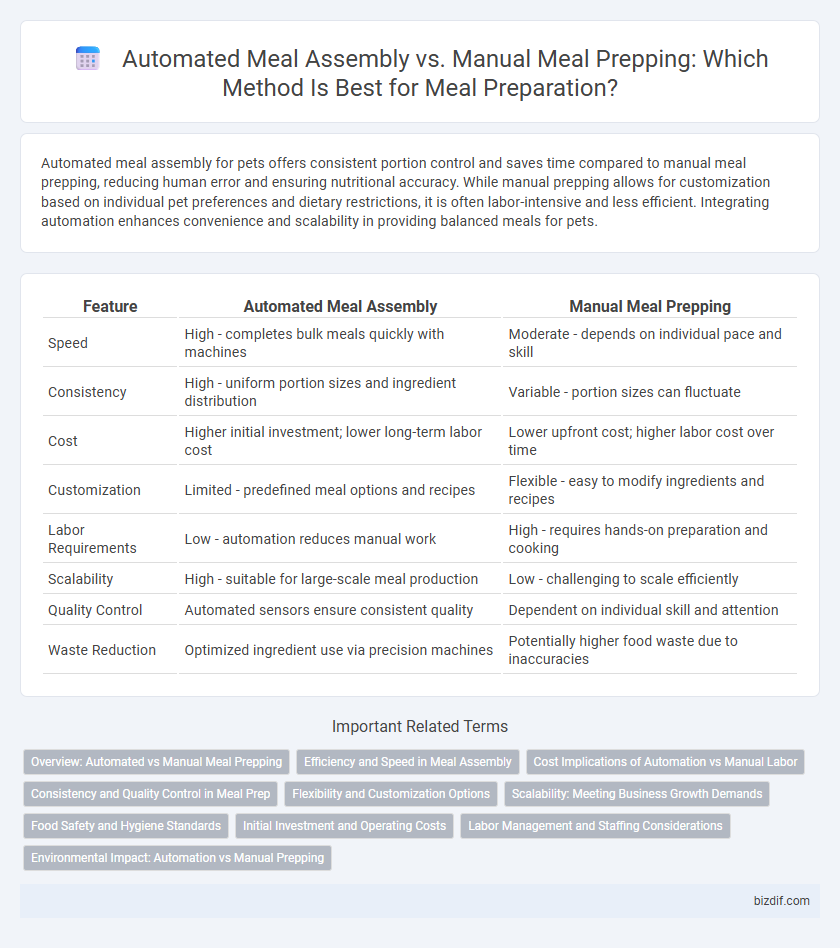

| Feature | Automated Meal Assembly | Manual Meal Prepping |

|---|---|---|

| Speed | High - completes bulk meals quickly with machines | Moderate - depends on individual pace and skill |

| Consistency | High - uniform portion sizes and ingredient distribution | Variable - portion sizes can fluctuate |

| Cost | Higher initial investment; lower long-term labor cost | Lower upfront cost; higher labor cost over time |

| Customization | Limited - predefined meal options and recipes | Flexible - easy to modify ingredients and recipes |

| Labor Requirements | Low - automation reduces manual work | High - requires hands-on preparation and cooking |

| Scalability | High - suitable for large-scale meal production | Low - challenging to scale efficiently |

| Quality Control | Automated sensors ensure consistent quality | Dependent on individual skill and attention |

| Waste Reduction | Optimized ingredient use via precision machines | Potentially higher food waste due to inaccuracies |

Overview: Automated vs Manual Meal Prepping

Automated meal assembly utilizes advanced machinery and technology to streamline ingredient sorting, portion control, and packaging, significantly reducing preparation time compared to manual meal prepping. Manual meal prepping involves hands-on chopping, cooking, and assembling, providing greater customization and flexibility but requiring more labor and time. Efficiency metrics demonstrate automated systems can increase meal output by up to 300%, while manual prepping remains ideal for personalized dietary needs and small batch cooking.

Efficiency and Speed in Meal Assembly

Automated meal assembly significantly increases efficiency by reducing manual labor and minimizing human error, allowing for faster production of large batches. Machines can consistently portion ingredients with precision, accelerating meal preparation times compared to traditional manual prepping. This speed and accuracy make automated systems ideal for commercial kitchens and meal delivery services seeking to optimize workflow and meet high demand.

Cost Implications of Automation vs Manual Labor

Automated meal assembly significantly reduces labor costs by minimizing the need for human intervention, leading to faster production and consistent portion control that lowers food waste. Manual meal prepping incurs higher ongoing labor expenses due to hourly wages, training, and potential inefficiencies in repetitive tasks. Initial investment in automation technology can be high, but long-term savings in operational costs and scalability make it a more cost-effective solution for large-scale meal production.

Consistency and Quality Control in Meal Prep

Automated meal assembly ensures uniform portion sizes and precise ingredient distribution, enhancing consistency across meals while reducing human error. Advanced machinery maintains strict quality control by monitoring temperature, hygiene, and ingredient freshness in real-time, surpassing manual meal prepping's variability. Automated systems allow scalability without compromising meal quality, ensuring reliable nutrient content and taste in every portion.

Flexibility and Customization Options

Automated meal assembly offers consistent portion control and streamlined processes but often limits flexibility in ingredient substitutions and customization. Manual meal prepping allows for complete control over ingredient choices, accommodating dietary restrictions and personal preferences with ease. This flexibility supports diverse nutritional needs and enhances the overall meal experience for individuals with specific dietary goals.

Scalability: Meeting Business Growth Demands

Automated meal assembly offers unparalleled scalability by streamlining production lines and reducing labor costs, enabling food businesses to rapidly increase output without compromising quality. In contrast, manual meal prepping is limited by human pace and variability, which constrains growth potential and consistency in large-scale operations. Investing in automated systems supports business expansion by efficiently meeting rising customer demand and maintaining standardized portion control.

Food Safety and Hygiene Standards

Automated meal assembly systems significantly reduce the risk of contamination by minimizing human contact, ensuring consistent adherence to strict food safety and hygiene standards through controlled environments and standardized processes. In contrast, manual meal prepping relies heavily on individual hygienic practices, increasing the potential for cross-contamination and variability in sanitation protocols. Technologies such as UV sterilization and automated sanitization in assembly lines enhance food safety, outperforming traditional manual methods in maintaining hygiene compliance and reducing bacterial risks.

Initial Investment and Operating Costs

Automated meal assembly requires a substantial initial investment in machinery and technology, often ranging from tens to hundreds of thousands of dollars depending on scale. Operating costs for automated systems include maintenance, energy consumption, and software updates, which may be balanced by increased production efficiency and labor savings. Manual meal prepping incurs lower startup costs but involves higher ongoing labor expenses and longer preparation times, impacting scalability and operational efficiency.

Labor Management and Staffing Considerations

Automated meal assembly significantly reduces labor costs by minimizing the need for repetitive manual tasks and allowing for consistent portion control, which improves operational efficiency in commercial kitchens. Manual meal prepping requires a larger, more flexible workforce capable of handling varied tasks such as chopping, mixing, and portioning, demanding greater labor management and higher staffing levels during peak times. Investing in automation can optimize staffing schedules and reduce turnover by alleviating physical labor burdens, but requires initial capital and technical expertise for maintenance.

Environmental Impact: Automation vs Manual Prepping

Automated meal assembly significantly reduces food waste by precisely measuring ingredients and optimizing portion control, leading to lower environmental footprints compared to manual meal prepping. Energy-efficient machines and streamlined logistics in automation minimize resource consumption and greenhouse gas emissions throughout the meal preparation process. Manual meal prepping often involves inconsistent portion sizes and higher food waste, contributing to increased environmental strain and resource inefficiency.

Automated meal assembly vs manual meal prepping Infographic

bizdif.com

bizdif.com