Centralized kitchen systems streamline meal prepping for pets by consolidating ingredient sourcing, cooking, and packaging in a single location, enhancing consistency and quality control. Decentralized production allows for localized preparation, reducing transportation time and costs while enabling customization based on regional pet dietary needs. Choosing between centralized and decentralized approaches depends on factors such as scale, budget, and the desired speed of delivery.

Table of Comparison

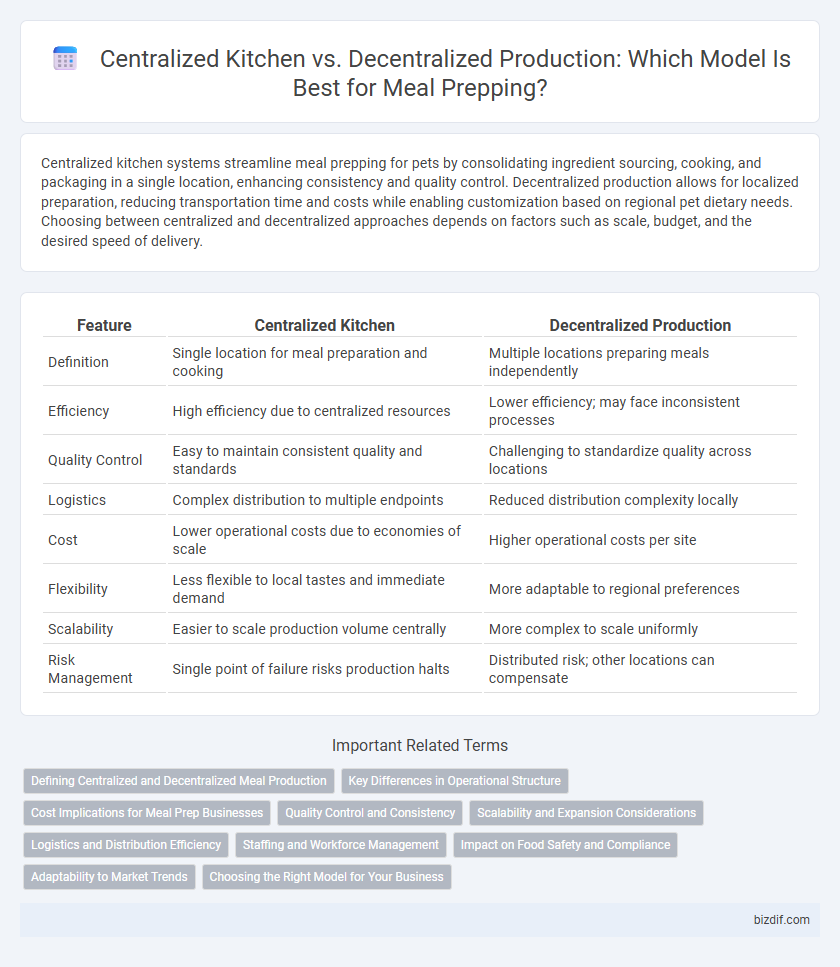

| Feature | Centralized Kitchen | Decentralized Production |

|---|---|---|

| Definition | Single location for meal preparation and cooking | Multiple locations preparing meals independently |

| Efficiency | High efficiency due to centralized resources | Lower efficiency; may face inconsistent processes |

| Quality Control | Easy to maintain consistent quality and standards | Challenging to standardize quality across locations |

| Logistics | Complex distribution to multiple endpoints | Reduced distribution complexity locally |

| Cost | Lower operational costs due to economies of scale | Higher operational costs per site |

| Flexibility | Less flexible to local tastes and immediate demand | More adaptable to regional preferences |

| Scalability | Easier to scale production volume centrally | More complex to scale uniformly |

| Risk Management | Single point of failure risks production halts | Distributed risk; other locations can compensate |

Defining Centralized and Decentralized Meal Production

Centralized meal production involves preparing large quantities of food in a single, central kitchen before distributing to multiple locations, ensuring consistent quality, streamlined inventory management, and reduced labor costs. Decentralized meal production refers to preparing meals at multiple smaller sites closer to the point of consumption, promoting customization, faster service, and reduced transportation time. Each method impacts food safety protocols, logistical complexity, and scalability differently within meal prepping operations.

Key Differences in Operational Structure

Centralized kitchens consolidate meal preparation in a single facility, enabling streamlined workflows, consistent quality control, and bulk ingredient purchasing, which reduces costs and waste. Decentralized production disperses cooking across multiple locations closer to end consumers, allowing tailored menus, faster delivery, and flexibility in responding to local demand variations. The operational structure of centralized kitchens relies on scale and standardization, while decentralized models prioritize agility and proximity to customers.

Cost Implications for Meal Prep Businesses

Centralized kitchens enable meal prep businesses to reduce overhead costs by consolidating equipment, labor, and ingredient purchasing, achieving economies of scale and minimizing waste. Decentralized production increases expenses due to duplicated resources, higher labor costs, and logistical complexities tied to managing multiple locations. Choosing centralized kitchen models often results in significant cost savings, allowing businesses to offer competitive pricing and improve profit margins.

Quality Control and Consistency

Centralized kitchens streamline quality control by consolidating production in a single location, ensuring uniform cooking processes and ingredient standards. This setup allows for consistent meal portions and taste, reducing variability compared to decentralized production. Decentralized production may face challenges in maintaining consistent quality due to varied local kitchen practices and equipment differences.

Scalability and Expansion Considerations

Centralized kitchens enable streamlined scalability by consolidating resources, reducing overhead costs, and ensuring consistent meal quality across larger production volumes. Decentralized production offers flexibility for rapid expansion into new markets, allowing localized adaptation and quicker response to demand fluctuations. Businesses must evaluate cost efficiency against market reach to optimize growth in meal prepping operations.

Logistics and Distribution Efficiency

Centralized kitchens streamline logistics by consolidating meal preparation in one location, reducing transportation costs and simplifying inventory management. Decentralized production enhances distribution efficiency through proximity to end consumers, minimizing delivery times and improving freshness. Choosing between these models impacts overall supply chain agility and operational scalability in meal prepping services.

Staffing and Workforce Management

Centralized kitchens streamline staffing by consolidating roles like chefs, food prep workers, and quality controllers in one location, enhancing coordination and reducing labor costs. Decentralized production requires a larger, distributed workforce trained to maintain consistent standards across multiple sites, increasing complexity in scheduling and supervision. Efficient workforce management in centralized setups leverages automated processes and specialized teams, whereas decentralized models depend heavily on local management and cross-training to ensure flexibility and responsiveness.

Impact on Food Safety and Compliance

Centralized kitchens streamline food safety protocols through standardized procedures and consistent quality control, reducing contamination risks compared to decentralized production. Decentralized production, while offering flexibility, often faces challenges in maintaining uniform compliance with health regulations across multiple locations. Implementing robust monitoring systems and staff training in decentralized setups is essential to uphold food safety standards and regulatory adherence.

Adaptability to Market Trends

Centralized kitchens enable efficient scaling and consistent quality control, allowing rapid adaptation to emerging meal trends through streamlined ingredient sourcing and standardized recipes. Decentralized production offers local flexibility, catering to regional tastes and dietary preferences, which enhances responsiveness to niche markets and evolving consumer demands. Balancing centralized consistency with decentralized customization maximizes adaptability in dynamic meal prepping markets.

Choosing the Right Model for Your Business

Selecting the ideal kitchen model depends on factors like scale, budget, and operational efficiency. Centralized kitchens streamline meal prepping by consolidating production under one roof, reducing overhead costs and enabling consistent quality control. Decentralized production offers flexibility and faster local delivery, making it suitable for businesses targeting diverse or geographically dispersed markets.

Centralized kitchen vs Decentralized production Infographic

bizdif.com

bizdif.com