Cold chain logistics ensure pet meals are stored and transported at consistently low temperatures, preserving freshness and preventing bacterial growth. Ambient storage, while more convenient and cost-effective, requires specially formulated pet meals with preservatives to maintain safety and nutritional quality at room temperature. Choosing between these methods depends on balancing shelf life, safety standards, and distribution costs.

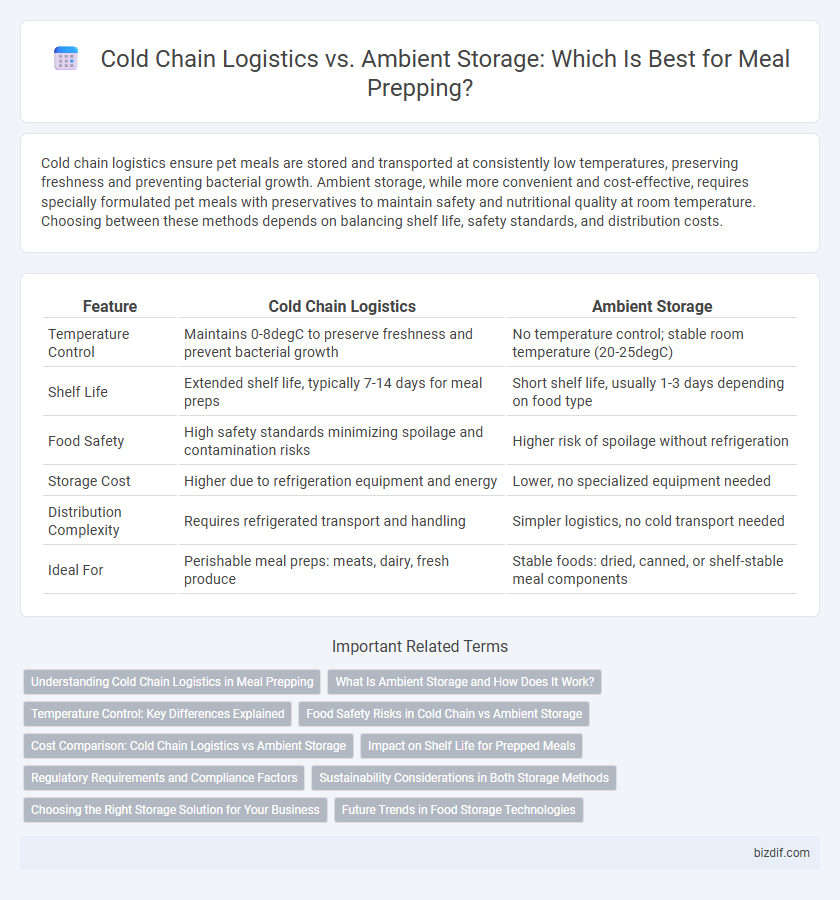

Table of Comparison

| Feature | Cold Chain Logistics | Ambient Storage |

|---|---|---|

| Temperature Control | Maintains 0-8degC to preserve freshness and prevent bacterial growth | No temperature control; stable room temperature (20-25degC) |

| Shelf Life | Extended shelf life, typically 7-14 days for meal preps | Short shelf life, usually 1-3 days depending on food type |

| Food Safety | High safety standards minimizing spoilage and contamination risks | Higher risk of spoilage without refrigeration |

| Storage Cost | Higher due to refrigeration equipment and energy | Lower, no specialized equipment needed |

| Distribution Complexity | Requires refrigerated transport and handling | Simpler logistics, no cold transport needed |

| Ideal For | Perishable meal preps: meats, dairy, fresh produce | Stable foods: dried, canned, or shelf-stable meal components |

Understanding Cold Chain Logistics in Meal Prepping

Cold chain logistics in meal prepping ensures perishable ingredients stay within a controlled temperature range, preserving freshness and preventing spoilage during transportation and storage. Unlike ambient storage, which relies on room temperature conditions, cold chain systems use refrigeration or freezing to maintain food safety and extend shelf life. Proper cold chain management reduces the risk of bacterial growth, maintaining the nutritional quality and flavor integrity of prepared meals.

What Is Ambient Storage and How Does It Work?

Ambient storage refers to the method of keeping meal-prepped foods at room temperature, typically between 20degC and 25degC, without the need for refrigeration or freezing. This storage technique relies on packaging technologies and preservatives that inhibit microbial growth and moisture exchange to maintain food safety and freshness. It is commonly used for shelf-stable products like dried snacks, canned meals, or vacuum-sealed items, offering convenience and reducing energy costs compared to cold chain logistics.

Temperature Control: Key Differences Explained

Cold chain logistics ensures meal prepped foods are stored and transported at consistently low temperatures, typically between 0degC and 4degC, to maintain freshness and prevent bacterial growth. Ambient storage allows meals to be kept at room temperature, generally between 20degC and 25degC, suitable for shelf-stable items but risking spoilage for perishable ingredients. The critical difference lies in temperature control precision, with cold chain logistics employing refrigeration technologies to preserve quality and extend shelf life, unlike ambient storage that relies on stable environmental conditions.

Food Safety Risks in Cold Chain vs Ambient Storage

Cold chain logistics maintain food safety by keeping meals at consistently low temperatures, preventing bacterial growth and spoilage during transportation and storage. Ambient storage poses higher food safety risks due to fluctuating temperatures that can accelerate microbial contamination and reduce shelf life. Effective cold chain management is essential to mitigate the risk of foodborne illnesses in meal prepping operations.

Cost Comparison: Cold Chain Logistics vs Ambient Storage

Cold chain logistics involve temperature-controlled transportation and storage, leading to higher operational costs due to refrigeration, specialized packaging, and energy consumption. Ambient storage eliminates the need for refrigeration, significantly reducing expenses but may limit the types of meals that can be safely stored and distributed. Evaluating cost comparison, ambient storage offers more budget-friendly solutions for meal prepping businesses focusing on shelf-stable products, while cold chain logistics are necessary for perishable meal options despite increased costs.

Impact on Shelf Life for Prepped Meals

Cold chain logistics significantly extend the shelf life of prepped meals by maintaining consistent refrigeration temperatures between 0degC and 4degC, which slows microbial growth and enzymatic reactions. Ambient storage, typically at room temperature around 20degC to 25degC, reduces shelf life due to increased microbial activity and faster spoilage rates in perishable ingredients. Employing cold chain logistics reduces food waste and preserves nutritional quality and flavor, making it essential for high-risk or protein-rich meal components.

Regulatory Requirements and Compliance Factors

Cold chain logistics in meal prepping mandates strict adherence to temperature-controlled environments, complying with FDA and HACCP regulations to prevent bacterial growth and ensure food safety. Ambient storage, while allowing for less stringent temperature controls, must still meet guidelines on moisture, packaging integrity, and shelf-life as dictated by regulatory bodies such as the USDA or EU food safety agencies. Compliance factors for both include thorough documentation, regular inspections, and validated processes to maintain food quality and legal accountability.

Sustainability Considerations in Both Storage Methods

Cold chain logistics in meal prepping requires energy-intensive refrigeration systems to maintain food safety, which can increase carbon emissions and contribute to environmental impact. Ambient storage relies on shelf-stable ingredients, reducing energy consumption but often needing preservatives that may affect sustainability. Choosing between cold chain and ambient storage involves balancing energy use, food waste reduction, and ingredient sourcing to optimize overall environmental benefits in meal prepping.

Choosing the Right Storage Solution for Your Business

Cold chain logistics ensures meal prep ingredients and finished meals remain at safe temperatures, preserving freshness and preventing bacterial growth, crucial for perishable items like dairy, seafood, and fresh produce. Ambient storage suits non-perishable or shelf-stable products such as grains, dried goods, and canned items, enabling cost-efficient inventory management without refrigeration needs. Selecting the right storage solution depends on product type, shelf life, and safety requirements, optimizing quality control and operational efficiency for your meal prep business.

Future Trends in Food Storage Technologies

Future trends in food storage technologies for meal prepping emphasize advancements in cold chain logistics, such as improved temperature-controlled transportation and smart monitoring systems, ensuring food freshness and safety. Ambient storage innovations include enhanced natural preservatives and modified atmosphere packaging that extend shelf life without refrigeration. Integration of IoT sensors and AI-driven predictive analytics will optimize storage conditions, reducing food waste and extending product quality in both cold chain and ambient environments.

Cold chain logistics vs Ambient storage Infographic

bizdif.com

bizdif.com