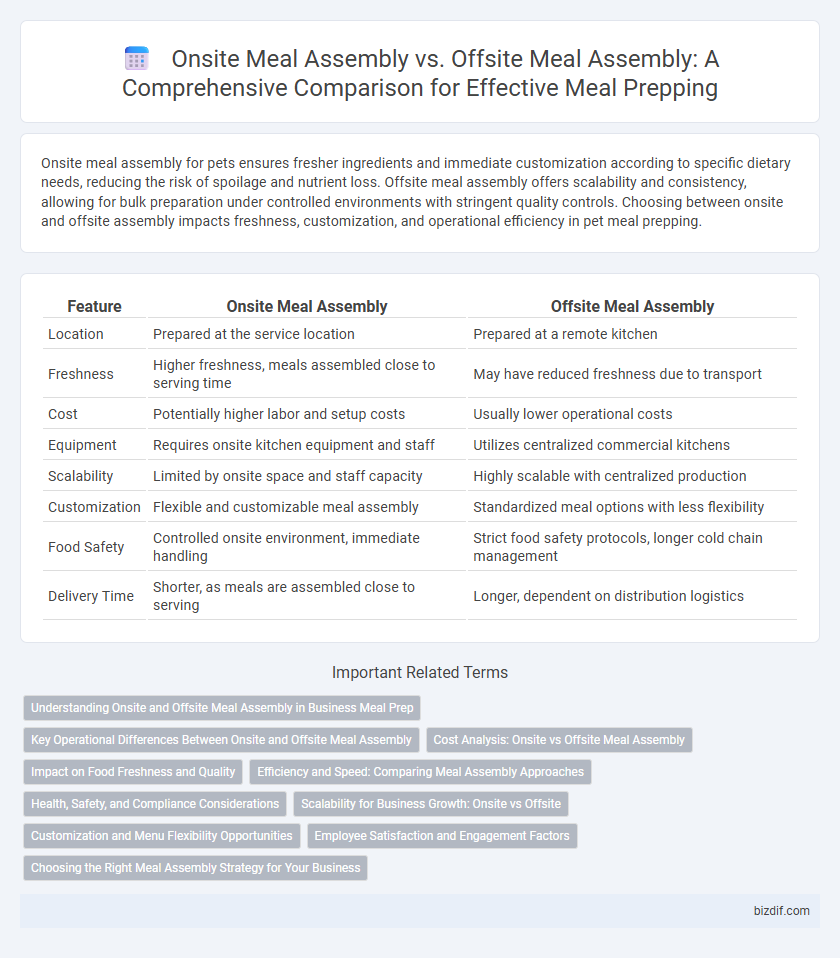

Onsite meal assembly for pets ensures fresher ingredients and immediate customization according to specific dietary needs, reducing the risk of spoilage and nutrient loss. Offsite meal assembly offers scalability and consistency, allowing for bulk preparation under controlled environments with stringent quality controls. Choosing between onsite and offsite assembly impacts freshness, customization, and operational efficiency in pet meal prepping.

Table of Comparison

| Feature | Onsite Meal Assembly | Offsite Meal Assembly |

|---|---|---|

| Location | Prepared at the service location | Prepared at a remote kitchen |

| Freshness | Higher freshness, meals assembled close to serving time | May have reduced freshness due to transport |

| Cost | Potentially higher labor and setup costs | Usually lower operational costs |

| Equipment | Requires onsite kitchen equipment and staff | Utilizes centralized commercial kitchens |

| Scalability | Limited by onsite space and staff capacity | Highly scalable with centralized production |

| Customization | Flexible and customizable meal assembly | Standardized meal options with less flexibility |

| Food Safety | Controlled onsite environment, immediate handling | Strict food safety protocols, longer cold chain management |

| Delivery Time | Shorter, as meals are assembled close to serving | Longer, dependent on distribution logistics |

Understanding Onsite and Offsite Meal Assembly in Business Meal Prep

Onsite meal assembly involves preparing and packaging meals directly at the business location, allowing for greater customization, freshness, and real-time quality control, which is essential for businesses prioritizing immediate consumer engagement. Offsite meal assembly is conducted at a separate centralized facility, enabling economies of scale, streamlined operations, and consistent portion control, making it ideal for businesses aiming to serve large volumes with standardized menus. Understanding the operational efficiencies, cost implications, and quality management of both onsite and offsite meal assembly models helps businesses optimize their meal prep strategies to align with customer expectations and logistical constraints.

Key Operational Differences Between Onsite and Offsite Meal Assembly

Onsite meal assembly involves preparing and packaging meals directly at the serving location, allowing for immediate quality control and customization based on real-time demand, while offsite meal assembly centralizes production in a dedicated facility, enhancing scalability and consistency through standardized processes. Onsite setups typically require more space and labor at each location, increasing operational complexity, whereas offsite assembly benefits from streamlined logistics but depends heavily on reliable distribution to maintain freshness. Inventory management for onsite assembly can be more flexible with direct ingredient sourcing, contrasting with offsite assembly's need for precise forecasting and cold-chain management.

Cost Analysis: Onsite vs Offsite Meal Assembly

Onsite meal assembly often incurs higher labor and facility expenses due to the need for dedicated kitchen space and staff, whereas offsite meal assembly can leverage centralized production lines to reduce overhead and labor costs. Offsite assembly benefits from economies of scale, lowering the cost per meal through bulk purchasing and streamlined operations. Evaluating transportation and packaging expenses is essential to understand the net cost differences between onsite and offsite meal assembly methods.

Impact on Food Freshness and Quality

Onsite meal assembly ensures optimal food freshness and quality by minimizing the time between preparation and consumption, preserving texture, flavor, and nutritional value. Offsite meal assembly often requires extended transportation and storage, increasing the risk of temperature fluctuations and nutrient degradation. Facilities choosing onsite assembly benefit from enhanced control over ingredient handling and immediate quality checks, crucial for maintaining high food standards.

Efficiency and Speed: Comparing Meal Assembly Approaches

Onsite meal assembly offers enhanced efficiency by enabling real-time quality control and immediate customization, reducing delays and errors. Offsite meal assembly leverages centralized production, optimizing speed through streamlined processes and bulk preparation, minimizing onsite labor requirements. Comparing both approaches reveals that onsite assembly excels in rapid adaptation to specific needs, while offsite assembly maximizes throughput through standardized workflows.

Health, Safety, and Compliance Considerations

Onsite meal assembly allows for direct oversight of hygiene practices, ensuring compliance with health regulations through real-time monitoring of food handling and sanitation procedures. Offsite meal assembly often requires rigorous transportation controls and packaging standards to maintain food safety and prevent contamination during delivery. Both methods must adhere to local health codes, but onsite assembly minimizes risks associated with temperature control and cross-contamination by limiting food exposure outside the preparation area.

Scalability for Business Growth: Onsite vs Offsite

Onsite meal assembly offers direct control over quality and immediate customization, making it suitable for small to medium-scale operations, but may face limitations in scalability due to space and labor constraints. Offsite meal assembly leverages centralized facilities with advanced automation, enabling high-volume production that supports rapid business growth and regional distribution. Choosing offsite assembly can optimize scalability by reducing overhead costs and streamlining processes essential for expanding meal prepping enterprises.

Customization and Menu Flexibility Opportunities

Onsite meal assembly offers greater customization and menu flexibility by allowing real-time adjustments based on individual preferences and dietary restrictions. In contrast, offsite meal assembly often involves pre-set menus with limited opportunities for personalization due to centralized production constraints. Businesses seeking tailored meal options and dynamic menu changes benefit significantly from the onsite assembly model.

Employee Satisfaction and Engagement Factors

Onsite meal assembly enhances employee satisfaction by allowing personalized meal choices and immediate feedback, fostering a sense of involvement and community among staff. Offsite meal assembly often streamlines operations but may reduce employee engagement due to limited interaction and customization options. Prioritizing onsite assembly can lead to higher morale and better alignment with dietary preferences, driving overall workplace engagement.

Choosing the Right Meal Assembly Strategy for Your Business

Onsite meal assembly offers greater control over ingredients and customization, ideal for businesses prioritizing freshness and customer preference. Offsite meal assembly provides efficiency and scalability by centralizing production, reducing labor costs, and streamlining distribution for high-volume operations. Evaluating factors such as budget, target market, and operational capacity is essential to selecting the most effective meal assembly strategy for your business success.

Onsite meal assembly vs Offsite meal assembly Infographic

bizdif.com

bizdif.com