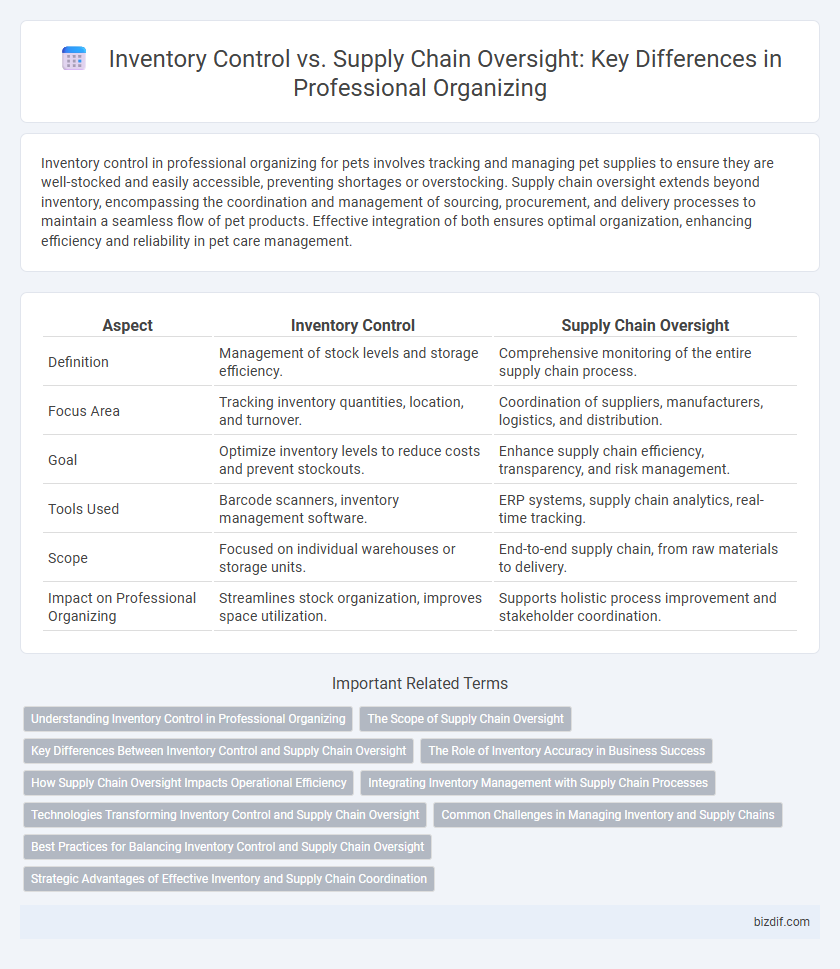

Inventory control in professional organizing for pets involves tracking and managing pet supplies to ensure they are well-stocked and easily accessible, preventing shortages or overstocking. Supply chain oversight extends beyond inventory, encompassing the coordination and management of sourcing, procurement, and delivery processes to maintain a seamless flow of pet products. Effective integration of both ensures optimal organization, enhancing efficiency and reliability in pet care management.

Table of Comparison

| Aspect | Inventory Control | Supply Chain Oversight |

|---|---|---|

| Definition | Management of stock levels and storage efficiency. | Comprehensive monitoring of the entire supply chain process. |

| Focus Area | Tracking inventory quantities, location, and turnover. | Coordination of suppliers, manufacturers, logistics, and distribution. |

| Goal | Optimize inventory levels to reduce costs and prevent stockouts. | Enhance supply chain efficiency, transparency, and risk management. |

| Tools Used | Barcode scanners, inventory management software. | ERP systems, supply chain analytics, real-time tracking. |

| Scope | Focused on individual warehouses or storage units. | End-to-end supply chain, from raw materials to delivery. |

| Impact on Professional Organizing | Streamlines stock organization, improves space utilization. | Supports holistic process improvement and stakeholder coordination. |

Understanding Inventory Control in Professional Organizing

Inventory control in professional organizing involves systematically categorizing, tracking, and maintaining accurate records of items to optimize space and accessibility. This process emphasizes real-time item counts, storage solutions, and minimizing excess belongings, differing from supply chain oversight, which manages the broader flow of goods from suppliers to end users. Mastering inventory control enables professional organizers to create efficient, clutter-free environments tailored to client needs.

The Scope of Supply Chain Oversight

Supply chain oversight encompasses a comprehensive management of the end-to-end processes involved in sourcing, production, and distribution, ensuring seamless coordination between suppliers, manufacturers, and retailers. Inventory control is a crucial subset focused primarily on monitoring stock levels, tracking product availability, and optimizing storage to prevent overstock or shortages. Effective supply chain oversight integrates inventory control with demand forecasting, supplier performance evaluation, and logistics management to enhance overall operational efficiency.

Key Differences Between Inventory Control and Supply Chain Oversight

Inventory control focuses on managing stock levels, tracking item availability, and ensuring accurate recording of goods within a warehouse or retail environment. Supply chain oversight encompasses a broader scope, including coordination of suppliers, production processes, logistics, and distribution to optimize the entire flow from raw materials to finished products. Key differences lie in inventory control's emphasis on real-time stock accuracy and reorder points, whereas supply chain oversight involves strategic planning, demand forecasting, and supplier relationship management.

The Role of Inventory Accuracy in Business Success

Inventory accuracy plays a critical role in professional organizing by ensuring that stock levels are correctly maintained and discrepancies are minimized. Accurate inventory control supports efficient supply chain oversight, reducing costs related to overstocking or stockouts and enhancing order fulfillment speed. Maintaining precise inventory records strengthens overall business success by improving customer satisfaction and operational efficiency.

How Supply Chain Oversight Impacts Operational Efficiency

Supply chain oversight enhances operational efficiency by ensuring timely flow of materials and accurate inventory levels, reducing delays and stockouts. Effective monitoring of supplier performance and logistics enables real-time adjustments, minimizing disruptions and optimizing resource allocation. This integrated approach allows professional organizers to maintain balanced inventory control, streamline workflows, and improve client satisfaction through consistent service delivery.

Integrating Inventory Management with Supply Chain Processes

Integrating inventory management with supply chain processes enhances real-time visibility, enabling precise demand forecasting and efficient stock replenishment. Streamlined coordination between inventory control and supply chain oversight reduces operational costs and prevents stockouts or overstock situations. Advanced technology platforms support seamless data sharing, fostering improved decision-making across procurement, warehousing, and distribution functions.

Technologies Transforming Inventory Control and Supply Chain Oversight

Advanced technologies like RFID, IoT sensors, and AI-powered analytics are revolutionizing inventory control by providing real-time tracking and predictive insights. Supply chain oversight benefits from blockchain for enhanced transparency and automated workflows that reduce operational delays. Integration of cloud-based platforms ensures seamless data synchronization, improving decision-making accuracy and efficiency across the entire supply network.

Common Challenges in Managing Inventory and Supply Chains

Common challenges in managing inventory and supply chains include inaccurate demand forecasting, leading to overstocking or stockouts, and lack of real-time visibility across multiple locations. Disjointed communication between suppliers, warehouses, and retailers often causes delays and errors in inventory replenishment. Inefficient inventory control systems can result in increased carrying costs and reduced customer satisfaction.

Best Practices for Balancing Inventory Control and Supply Chain Oversight

Best practices for balancing inventory control and supply chain oversight emphasize accurate demand forecasting and real-time data integration to minimize stockouts and excess inventory. Implementing automated inventory tracking systems and regularly reviewing supplier performance enhances operational efficiency and responsiveness. Cross-functional collaboration between inventory managers and supply chain teams ensures alignment and agility in adapting to market fluctuations.

Strategic Advantages of Effective Inventory and Supply Chain Coordination

Effective coordination between inventory control and supply chain oversight enhances operational efficiency by reducing stockouts and excess inventory, leading to improved cash flow management. Leveraging real-time data integration enables predictive demand forecasting, optimizing resource allocation and minimizing costs. Strategic alignment of these functions supports faster response times to market fluctuations, strengthening competitive advantage and customer satisfaction.

inventory control vs supply chain oversight Infographic

bizdif.com

bizdif.com