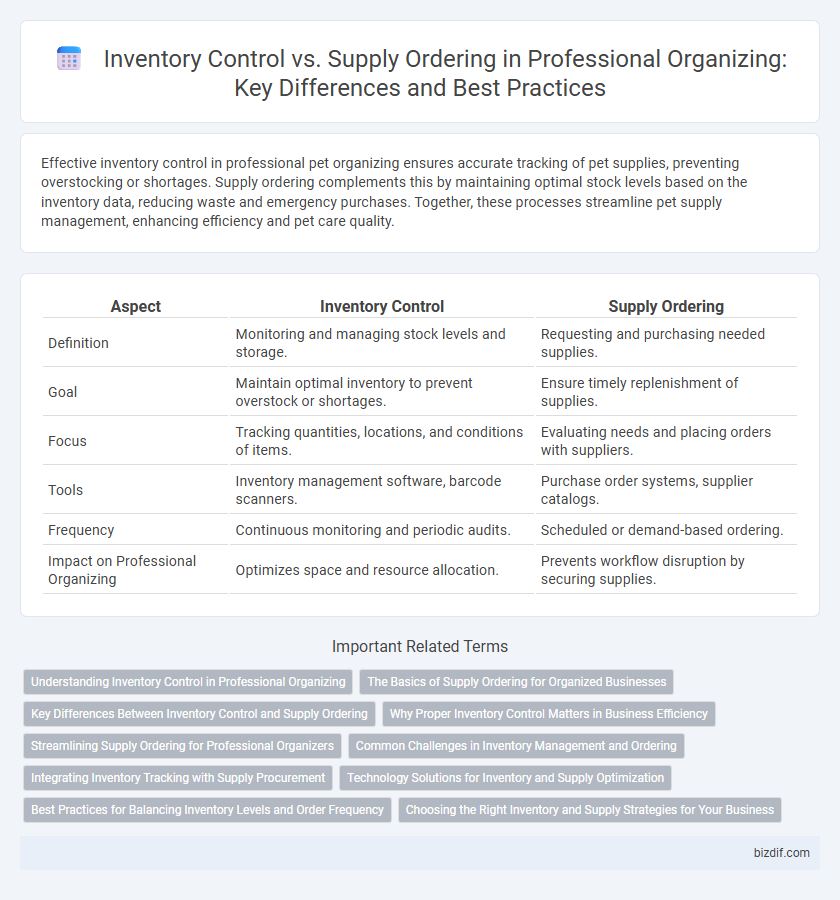

Effective inventory control in professional pet organizing ensures accurate tracking of pet supplies, preventing overstocking or shortages. Supply ordering complements this by maintaining optimal stock levels based on the inventory data, reducing waste and emergency purchases. Together, these processes streamline pet supply management, enhancing efficiency and pet care quality.

Table of Comparison

| Aspect | Inventory Control | Supply Ordering |

|---|---|---|

| Definition | Monitoring and managing stock levels and storage. | Requesting and purchasing needed supplies. |

| Goal | Maintain optimal inventory to prevent overstock or shortages. | Ensure timely replenishment of supplies. |

| Focus | Tracking quantities, locations, and conditions of items. | Evaluating needs and placing orders with suppliers. |

| Tools | Inventory management software, barcode scanners. | Purchase order systems, supplier catalogs. |

| Frequency | Continuous monitoring and periodic audits. | Scheduled or demand-based ordering. |

| Impact on Professional Organizing | Optimizes space and resource allocation. | Prevents workflow disruption by securing supplies. |

Understanding Inventory Control in Professional Organizing

Inventory control in professional organizing involves systematically tracking and categorizing client belongings to maintain an accurate count and location of items, ensuring efficient space utilization and easy retrieval. It emphasizes implementing storage solutions, labeling systems, and regular audits to prevent clutter and overstocking. Effective inventory control supports streamlined supply ordering by identifying exact needs, reducing waste, and optimizing budget allocation.

The Basics of Supply Ordering for Organized Businesses

Effective supply ordering relies on accurate inventory control to maintain optimal stock levels and prevent disruptions in organized businesses. Implementing systematic tracking methods ensures timely replenishment, minimizes excess inventory, and supports operational efficiency. Prioritizing real-time data analysis helps businesses forecast demand and streamline procurement processes.

Key Differences Between Inventory Control and Supply Ordering

Inventory control involves tracking, managing, and optimizing existing stock levels to prevent overstocking or shortages, ensuring efficient use of resources. Supply ordering focuses on the procurement process, including selecting suppliers, placing orders, and scheduling deliveries to replenish inventory. Key differences lie in inventory control's emphasis on monitoring and balancing stock, while supply ordering centers on the acquisition and timing of supplies.

Why Proper Inventory Control Matters in Business Efficiency

Proper inventory control ensures accurate tracking of stock levels, reducing waste and preventing overstock or stockouts that disrupt business operations. Efficient inventory management streamlines supply ordering, aligning purchases with actual demand to optimize cash flow and minimize storage costs. Implementing robust inventory control systems enhances overall business efficiency by enabling timely decision-making and improving customer satisfaction through consistent product availability.

Streamlining Supply Ordering for Professional Organizers

Streamlining supply ordering enhances efficiency by automating inventory tracking and reducing manual errors, allowing professional organizers to maintain optimal stock levels without overordering. Integrating inventory control systems with supply vendors ensures real-time updates on available products and anticipates reorder points, minimizing downtime. This seamless process supports timely project execution and cost savings by preventing supply shortages and excess inventory.

Common Challenges in Inventory Management and Ordering

Inventory control commonly faces challenges such as inaccurate stock tracking, leading to either overstocking or stockouts that disrupt workflow. Supply ordering often struggles with delayed deliveries and inconsistent supplier reliability, complicating timely replenishment. Efficient inventory management demands synchronized systems that minimize human error and forecast demand accurately to streamline ordering processes.

Integrating Inventory Tracking with Supply Procurement

Integrating inventory tracking with supply procurement streamlines professional organizing by ensuring real-time visibility of stock levels and automatic reorder triggers for essential supplies. Accurate inventory control minimizes overstock and stockouts, optimizing resource allocation and reducing operational costs. This seamless connection enhances efficiency by syncing data across systems, enabling timely and informed purchasing decisions tailored to client needs.

Technology Solutions for Inventory and Supply Optimization

Technology solutions for inventory and supply optimization in professional organizing include advanced software platforms that integrate real-time tracking with automated reorder alerts, ensuring precise inventory control. These tools utilize barcode scanning, RFID tagging, and AI-driven analytics to monitor stock levels, predict demand, and reduce excess supplies. Cloud-based systems enable seamless supply ordering by synchronizing data across multiple locations, improving efficiency and minimizing manual errors.

Best Practices for Balancing Inventory Levels and Order Frequency

Effective inventory control in professional organizing involves accurately tracking item usage rates and seasonal demand patterns to prevent overstocking or stockouts. Implementing just-in-time supply ordering maximizes storage space and reduces carrying costs by aligning order frequency with actual consumption data. Utilizing inventory management software enables precise forecasting and timely reorder alerts, striking an optimal balance between inventory levels and order frequency.

Choosing the Right Inventory and Supply Strategies for Your Business

Effective inventory control involves tracking stock levels, managing storage efficiently, and minimizing excess or obsolete items, ensuring smooth operations and cost savings. Supply ordering focuses on timely procurement, supplier reliability, and optimizing order quantities to prevent disruptions and maintain service quality. Selecting the right balance between inventory control and supply ordering strategies enhances cash flow management and supports scalable business growth.

inventory control vs supply ordering Infographic

bizdif.com

bizdif.com