LEAN organizing enhances efficiency by eliminating waste and streamlining processes in pet-related spaces, while the 5S methodology emphasizes systematic organization through Sort, Set in order, Shine, Standardize, and Sustain principles. Both approaches improve pet area management, but LEAN focuses on value flow and minimizing non-value activities, whereas 5S creates a clean, organized environment that supports consistent pet care routines. Integrating LEAN and 5S leads to optimal functionality and cleanliness in professional pet organizing.

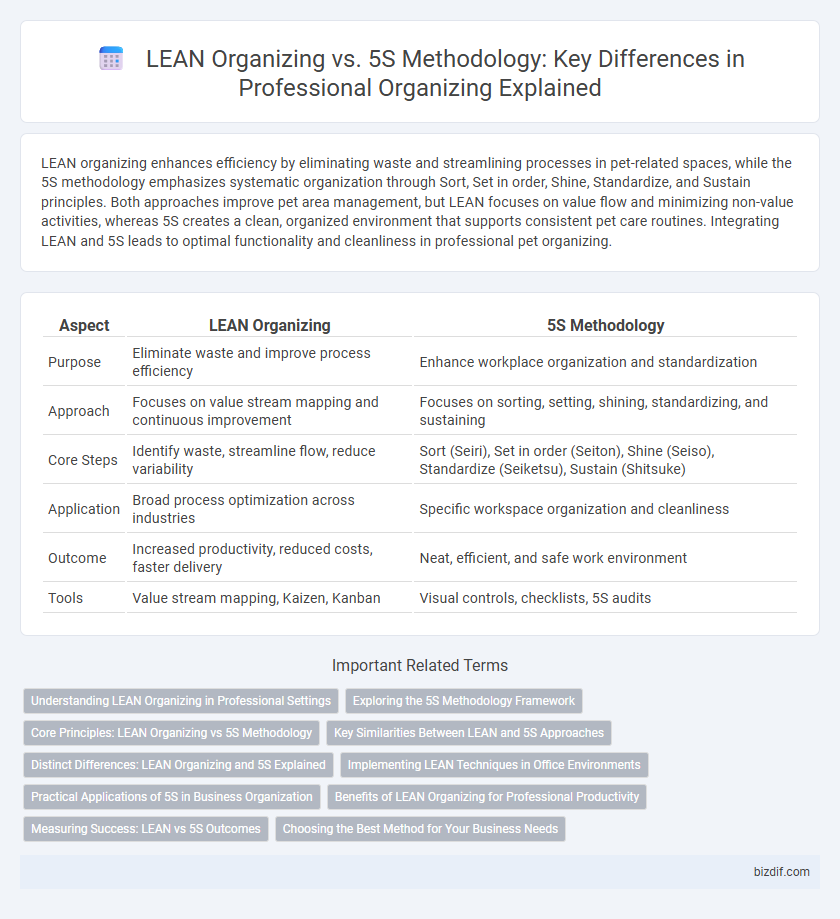

Table of Comparison

| Aspect | LEAN Organizing | 5S Methodology |

|---|---|---|

| Purpose | Eliminate waste and improve process efficiency | Enhance workplace organization and standardization |

| Approach | Focuses on value stream mapping and continuous improvement | Focuses on sorting, setting, shining, standardizing, and sustaining |

| Core Steps | Identify waste, streamline flow, reduce variability | Sort (Seiri), Set in order (Seiton), Shine (Seiso), Standardize (Seiketsu), Sustain (Shitsuke) |

| Application | Broad process optimization across industries | Specific workspace organization and cleanliness |

| Outcome | Increased productivity, reduced costs, faster delivery | Neat, efficient, and safe work environment |

| Tools | Value stream mapping, Kaizen, Kanban | Visual controls, checklists, 5S audits |

Understanding LEAN Organizing in Professional Settings

LEAN organizing in professional settings emphasizes waste reduction, efficiency, and continuous improvement by streamlining processes and optimizing workflow. Unlike the 5S methodology, which focuses primarily on workplace organization through Sort, Set in order, Shine, Standardize, and Sustain, LEAN organizing integrates broader operational strategies such as value stream mapping and employee involvement to enhance productivity. Implementing LEAN organizing in offices or workspaces leads to minimized downtime, enhanced task clarity, and improved resource allocation.

Exploring the 5S Methodology Framework

The 5S methodology framework consists of five key principles: Sort, Set in Order, Shine, Standardize, and Sustain, designed to enhance workplace organization and efficiency. This structured approach prioritizes eliminating waste, improving workflow, and maintaining a clean, organized environment, which supports continuous improvement. Compared to LEAN organizing, 5S offers a more specific, step-by-step process that serves as a foundational tool within broader LEAN strategies for optimizing productivity.

Core Principles: LEAN Organizing vs 5S Methodology

LEAN organizing centers on maximizing value by eliminating waste through continuous improvement and streamlining workflows to enhance productivity. The 5S methodology focuses on workplace organization and standardization through five stages: Sort, Set in order, Shine, Standardize, and Sustain, creating a clean and efficient environment. Both approaches emphasize efficiency, but LEAN organizes processes holistically while 5S targets physical workspace order and cleanliness.

Key Similarities Between LEAN and 5S Approaches

LEAN organizing and 5S methodology both focus on improving workplace efficiency by eliminating waste and promoting standardized processes. Each approach emphasizes sorting, setting in order, shining, standardizing, and sustaining organization to enhance productivity and reduce clutter. Both methodologies foster continuous improvement and employee engagement through visual management and systematic problem-solving techniques.

Distinct Differences: LEAN Organizing and 5S Explained

LEAN Organizing focuses on eliminating waste and streamlining workflows across entire processes to enhance efficiency and productivity, while the 5S methodology emphasizes organizing physical spaces through Sort, Set in order, Shine, Standardize, and Sustain to create a clean and orderly work environment. LEAN employs broader continuous improvement principles applicable to various business functions, whereas 5S serves as a foundational tool within LEAN for maintaining workplace organization and discipline. The key distinction lies in LEAN's strategic process optimization versus 5S's tactical, workspace-specific organizational techniques.

Implementing LEAN Techniques in Office Environments

LEAN organizing in office environments emphasizes waste reduction and process streamlining by identifying non-value-added activities, improving workflow efficiency, and enhancing team collaboration. The 5S methodology--Sort, Set in order, Shine, Standardize, and Sustain--serves as a foundational tool within LEAN, focusing on workplace organization, visual management, and maintaining order to support continuous improvement. Implementing LEAN techniques alongside 5S in offices leads to optimized space utilization, faster information retrieval, and improved productivity through standardized procedures and waste elimination.

Practical Applications of 5S in Business Organization

5S methodology enhances business organization by implementing Sort, Set in Order, Shine, Standardize, and Sustain to streamline workflows and eliminate waste. Practical applications include organizing workspaces for improved efficiency, ensuring tools and documents are easily accessible, and maintaining cleanliness to boost employee productivity and safety. Unlike LEAN, which focuses broadly on process improvement, 5S specifically targets workplace organization as a foundational step toward operational excellence.

Benefits of LEAN Organizing for Professional Productivity

LEAN organizing streamlines workflows by eliminating waste and optimizing processes, significantly enhancing professional productivity. Unlike the 5S methodology, which emphasizes workplace organization and standardization, LEAN focuses on continuous improvement and value generation, resulting in faster task completion and reduced errors. Implementing LEAN organizing leads to better resource utilization, increased efficiency, and improved employee engagement in professional settings.

Measuring Success: LEAN vs 5S Outcomes

LEAN organizing emphasizes continuous improvement through waste reduction and efficiency metrics such as cycle time, throughput, and customer satisfaction scores. The 5S methodology focuses on workplace organization and standardization, using visual audits and compliance rates to measure success. Both approaches yield productivity gains, but LEAN provides broader operational insights while 5S ensures sustained orderliness and safety.

Choosing the Best Method for Your Business Needs

LEAN organizing emphasizes eliminating waste and improving workflow efficiency by continuously identifying value-added activities, making it ideal for businesses seeking dynamic process optimization. The 5S methodology--Sort, Set in order, Shine, Standardize, and Sustain--provides a structured approach to workplace organization that enhances cleanliness, safety, and consistency, perfect for environments requiring disciplined spatial management. Selecting between LEAN organizing and 5S depends on business goals, with LEAN suited for ongoing operational improvements and 5S excelling in establishing foundational order and standardization.

LEAN organizing vs 5S methodology Infographic

bizdif.com

bizdif.com