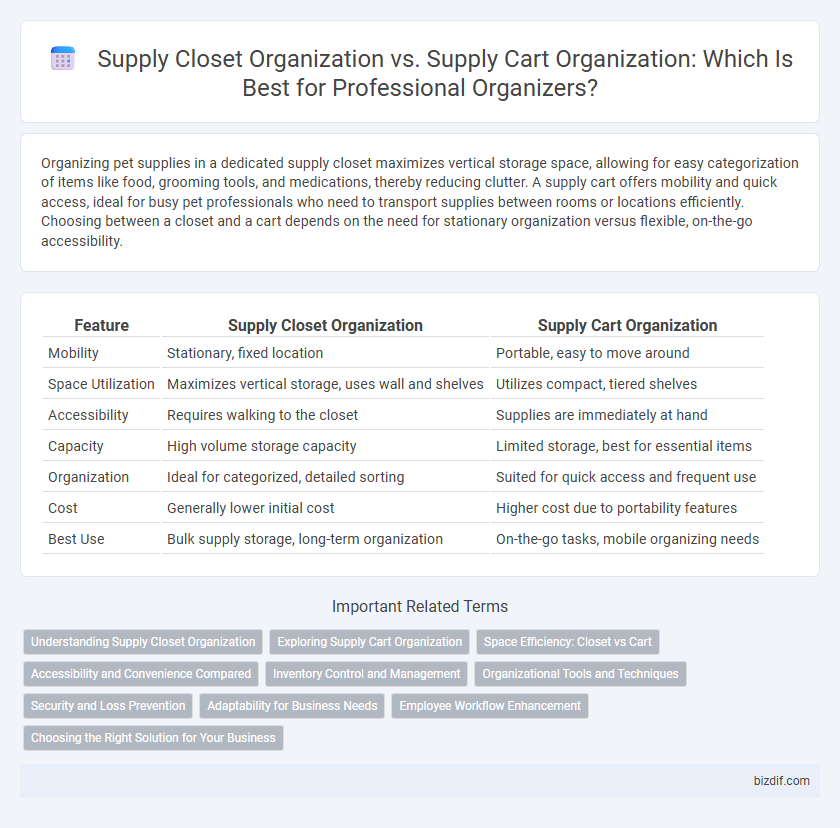

Organizing pet supplies in a dedicated supply closet maximizes vertical storage space, allowing for easy categorization of items like food, grooming tools, and medications, thereby reducing clutter. A supply cart offers mobility and quick access, ideal for busy pet professionals who need to transport supplies between rooms or locations efficiently. Choosing between a closet and a cart depends on the need for stationary organization versus flexible, on-the-go accessibility.

Table of Comparison

| Feature | Supply Closet Organization | Supply Cart Organization |

|---|---|---|

| Mobility | Stationary, fixed location | Portable, easy to move around |

| Space Utilization | Maximizes vertical storage, uses wall and shelves | Utilizes compact, tiered shelves |

| Accessibility | Requires walking to the closet | Supplies are immediately at hand |

| Capacity | High volume storage capacity | Limited storage, best for essential items |

| Organization | Ideal for categorized, detailed sorting | Suited for quick access and frequent use |

| Cost | Generally lower initial cost | Higher cost due to portability features |

| Best Use | Bulk supply storage, long-term organization | On-the-go tasks, mobile organizing needs |

Understanding Supply Closet Organization

Supply closet organization involves allocating designated storage spaces for bulk supplies, maximizing vertical shelving, clear labeling, and systematic categorization to ensure easy access and inventory management. Using adjustable shelving units and transparent containers enhances visibility and minimizes search time, making it easier to track supply levels and reorder efficiently. Properly organized supply closets reduce clutter, improve workflow, and support consistent restocking practices in professional settings.

Exploring Supply Cart Organization

Supply cart organization enhances mobility and accessibility, allowing professionals to efficiently transport tools and materials across multiple workstations. Compared to supply closets, carts offer real-time inventory management by keeping essential items within immediate reach, reducing downtime and improving workflow. Prioritizing ergonomic design in supply carts maximizes storage capacity while maintaining ease of movement in confined spaces.

Space Efficiency: Closet vs Cart

Supply closet organization maximizes vertical space with shelves, bins, and hooks, making it ideal for storing a large volume of supplies in a compact area, which reduces clutter and improves accessibility. In contrast, supply cart organization offers mobility and flexibility but typically provides limited storage capacity and less efficient use of vertical space. Businesses needing to optimize space for extensive supplies usually benefit more from a well-designed supply closet.

Accessibility and Convenience Compared

Supply closet organization often provides a centralized storage solution with clearly labeled shelves and bins, enhancing accessibility for larger teams and ensuring supplies are easy to locate. Supply cart organization offers mobility and convenience by allowing users to transport essential materials directly to the point of use, reducing time spent retrieving items. Both methods improve workflow efficiency, but supply carts excel in dynamic environments requiring frequent movement, while supply closets suit static, high-volume storage needs.

Inventory Control and Management

Supply closet organization centralizes inventory, allowing for comprehensive stock tracking and minimizing overordering through consistent visual audits, which enhances bulk management efficiency. Supply cart organization supports mobility and immediate access to essential items, improving workflow for on-the-go tasks but may require more frequent restocking due to limited capacity. Effective inventory control integrates digital tracking tools to monitor usage patterns and prevent stockouts regardless of storage method.

Organizational Tools and Techniques

Supply closet organization employs fixed shelving, labeled bins, and pegboards to maximize vertical space and ensure easy inventory management. Supply cart organization uses portable trays, modular compartments, and clear containers to enhance mobility and streamline access during activities. Both utilize color-coded systems and inventory tracking apps to maintain order and efficiency tailored to stationary or mobile needs.

Security and Loss Prevention

Supply closet organization enhances security by centralizing inventory in a locked, restricted-access area, reducing the risk of unauthorized use and minimizing loss. Supply carts, while mobile and convenient, present higher theft and misplacement risks due to their constant movement and limited physical security measures. Implementing barcode tracking and access controls in supply closets further strengthens loss prevention efforts compared to supply carts.

Adaptability for Business Needs

Supply closet organization offers a stationary, centralized solution ideal for businesses with fixed workspaces, providing easy inventory management and bulk storage capacity. Supply cart organization enhances adaptability by allowing mobility across various work areas, optimizing efficiency in dynamic or multi-location environments. Choosing between supply closets and carts depends on the need for either fixed accessibility or flexible, on-the-go supply management tailored to specific business operations.

Employee Workflow Enhancement

Organizing a supply closet centralizes materials for easy access and inventory management, reducing time spent searching for items during busy work periods. In contrast, a supply cart enhances mobility by bringing essential supplies directly to the employee's workspace, minimizing downtime and streamlining workflow. Employee productivity improves when storage solutions align with task demands, balancing centralized storage with on-the-go accessibility.

Choosing the Right Solution for Your Business

Supply closet organization maximizes fixed storage space with categorized shelves and labeled containers, ideal for businesses needing centralized inventory control. Supply cart organization provides mobility and quick access to essential items, perfect for dynamic work environments requiring frequent item relocation. Evaluating workflow patterns and space constraints helps determine whether a stationary supply closet or a portable supply cart best supports operational efficiency.

supply closet organization vs supply cart organization Infographic

bizdif.com

bizdif.com