Curing time in soap making is crucial for ensuring hardness, mildness, and longer-lasting bars, while ready-to-sell soap refers to finished products that have fully cured and are safe for use. Insufficient curing may result in soap that is too soft or harsh on the skin, impacting customer satisfaction and durability. Properly cured soap not only improves quality but also enhances the overall pet-safe product experience.

Table of Comparison

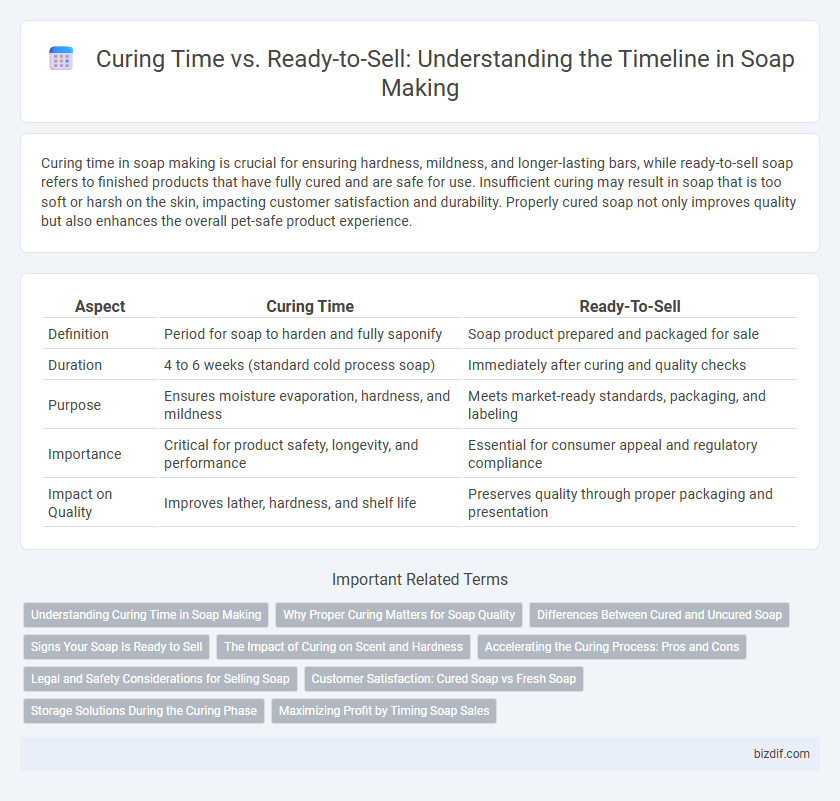

| Aspect | Curing Time | Ready-To-Sell |

|---|---|---|

| Definition | Period for soap to harden and fully saponify | Soap product prepared and packaged for sale |

| Duration | 4 to 6 weeks (standard cold process soap) | Immediately after curing and quality checks |

| Purpose | Ensures moisture evaporation, hardness, and mildness | Meets market-ready standards, packaging, and labeling |

| Importance | Critical for product safety, longevity, and performance | Essential for consumer appeal and regulatory compliance |

| Impact on Quality | Improves lather, hardness, and shelf life | Preserves quality through proper packaging and presentation |

Understanding Curing Time in Soap Making

Curing time in soap making is the essential period during which soap hardens, loses excess water, and completes saponification, typically lasting 4 to 6 weeks. Proper curing enhances soap quality by improving hardness, lather, and longevity, making it safe and effective for use. Selling soap prematurely before adequate curing can result in a softer product prone to quicker deterioration and reduced customer satisfaction.

Why Proper Curing Matters for Soap Quality

Proper curing time in soap making is crucial to ensure complete saponification and water evaporation, which directly impacts soap hardness and longevity. Insufficient curing results in soft, overly alkaline soap that can irritate the skin and deteriorate quickly. Allowing soap to cure for 4 to 6 weeks enhances its quality, moisturizing properties, and overall user safety, making it ready-to-sell with optimal performance.

Differences Between Cured and Uncured Soap

Curing time in soap making refers to the period during which soap undergoes saponification and excess water evaporation, typically lasting 4 to 6 weeks. Uncured soap contains higher moisture levels, resulting in softer texture and reduced lather quality, while cured soap is harder, longer-lasting, and offers improved cleansing and skin benefits. Understanding the differences between cured and uncured soap ensures optimal product quality and customer satisfaction for ready-to-sell soap batches.

Signs Your Soap Is Ready to Sell

Proper soap curing time typically ranges from 4 to 6 weeks, allowing excess water to evaporate and the soap to harden, resulting in a longer-lasting bar. Key signs your soap is ready to sell include a firm texture that doesn't dent when pressed, a neutral or pleasant scent indicating full saponification, and a smooth surface free from excess moisture or tackiness. Testing the soap's pH level, which should ideally be between 7 and 10, ensures safety for skin and confirms readiness for retail.

The Impact of Curing on Scent and Hardness

Curing time significantly influences both the scent and hardness of handmade soap, with longer curing periods allowing excess water to evaporate and essential oils to fully mature. This process enhances the soap's hardness, resulting in longer-lasting bars, while also intensifying and stabilizing the fragrance for a more consistent scent experience. Soap typically reaches its optimal ready-to-sell condition after 4 to 6 weeks of curing, balancing durability and aromatic quality.

Accelerating the Curing Process: Pros and Cons

Accelerating the soap curing process, typically shortened from the standard 4-6 weeks, can speed up time to market but may compromise the soap's hardness, lather quality, and long-term durability. Techniques such as using higher temperatures, fans, or dehumidifiers can reduce water content faster, yet risk uneven curing and potential skin irritation due to residual alkali. Manufacturers must balance the benefits of quicker sales cycles against possible declines in soap performance and customer satisfaction.

Legal and Safety Considerations for Selling Soap

Soap curing time directly impacts its pH balance and moisture content, which are critical for consumer safety and compliance with regulatory standards such as FDA guidelines. Selling soap before the recommended curing period risks skin irritation due to incomplete saponification and insufficient hardness, potentially violating product safety laws. Ensuring a minimum curing time of 4-6 weeks allows for chemical stabilization, reducing liability and meeting legal requirements for safe market distribution.

Customer Satisfaction: Cured Soap vs Fresh Soap

Curing time significantly impacts customer satisfaction by enhancing soap hardness, longevity, and lather quality, making cured soap more desirable than fresh soap immediately after production. Fresh soap often contains excess moisture and alkaline substances, which can cause skin irritation and reduce overall performance, whereas properly cured soap offers a gentle, long-lasting cleansing experience. Prioritizing curing time ensures a premium product that meets customer expectations for durability, safety, and effectiveness.

Storage Solutions During the Curing Phase

Proper storage solutions during the curing phase of soap making are essential to ensure optimal drying and hardness, which typically takes 4 to 6 weeks. Using well-ventilated shelving units in a cool, dry environment prevents moisture buildup and promotes even curing. Airtight containers or plastic wrap should be avoided, as they can trap humidity and extend curing time, delaying readiness for sale.

Maximizing Profit by Timing Soap Sales

Curing time directly impacts soap hardness, lather quality, and moisture content, which are critical for customer satisfaction and repeat sales. Releasing soap too early may lead to poor texture and faster deterioration, reducing brand reputation and profitability. Optimizing curing periods enhances product value, enabling higher pricing and maximizing profit margins in competitive markets.

Curing Time vs Ready-To-Sell Infographic

bizdif.com

bizdif.com