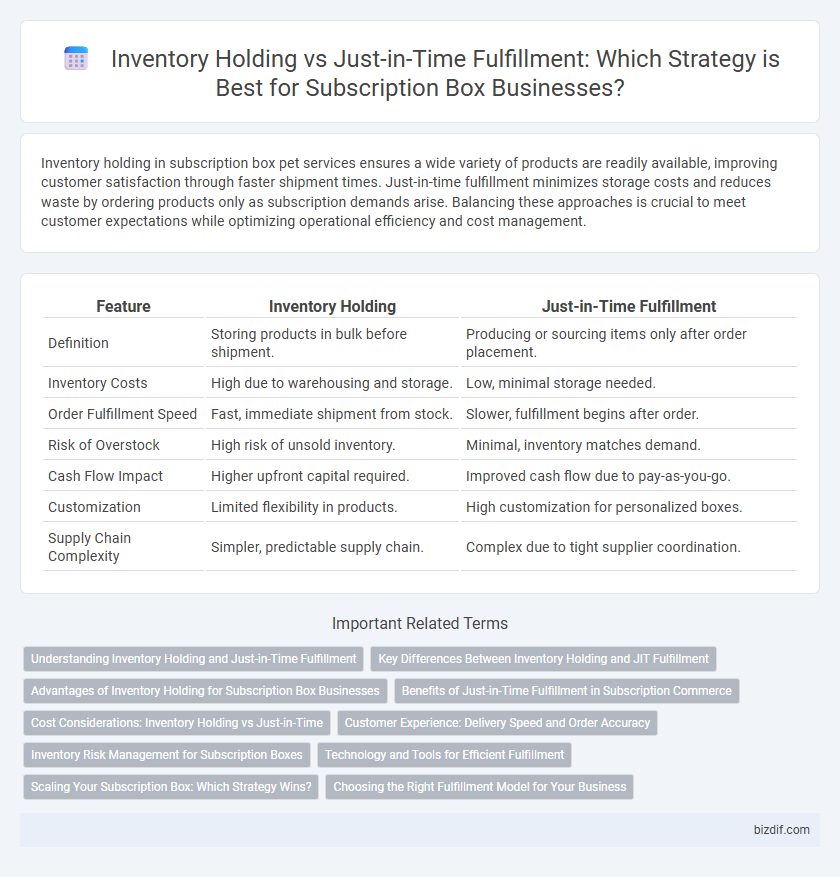

Inventory holding in subscription box pet services ensures a wide variety of products are readily available, improving customer satisfaction through faster shipment times. Just-in-time fulfillment minimizes storage costs and reduces waste by ordering products only as subscription demands arise. Balancing these approaches is crucial to meet customer expectations while optimizing operational efficiency and cost management.

Table of Comparison

| Feature | Inventory Holding | Just-in-Time Fulfillment |

|---|---|---|

| Definition | Storing products in bulk before shipment. | Producing or sourcing items only after order placement. |

| Inventory Costs | High due to warehousing and storage. | Low, minimal storage needed. |

| Order Fulfillment Speed | Fast, immediate shipment from stock. | Slower, fulfillment begins after order. |

| Risk of Overstock | High risk of unsold inventory. | Minimal, inventory matches demand. |

| Cash Flow Impact | Higher upfront capital required. | Improved cash flow due to pay-as-you-go. |

| Customization | Limited flexibility in products. | High customization for personalized boxes. |

| Supply Chain Complexity | Simpler, predictable supply chain. | Complex due to tight supplier coordination. |

Understanding Inventory Holding and Just-in-Time Fulfillment

Inventory holding involves maintaining a stockpile of products to meet demand immediately, reducing delivery times but increasing storage costs and risk of excess inventory. Just-in-time fulfillment minimizes inventory levels by receiving goods only as needed, optimizing cash flow and reducing waste but requiring precise demand forecasting and supplier reliability. Balancing these strategies can enhance operational efficiency and customer satisfaction in subscription box services.

Key Differences Between Inventory Holding and JIT Fulfillment

Inventory holding requires maintaining stock on-site, leading to higher storage costs and potential overstock risks, whereas Just-in-time fulfillment minimizes inventory by procuring products as orders arrive, reducing storage expenses and waste. Inventory holding allows faster order processing and higher product availability but demands accurate demand forecasting to avoid excess stock. Just-in-time fulfillment offers greater flexibility and cash flow management, relying heavily on reliable supplier lead times and efficient logistics to prevent delays in delivery.

Advantages of Inventory Holding for Subscription Box Businesses

Inventory holding in subscription box businesses ensures immediate product availability, reducing shipping delays and enhancing customer satisfaction. Maintaining stock allows for better demand forecasting, bulk purchasing discounts, and efficient packaging processes, ultimately lowering overall costs. This approach also supports smoother customization options and reliable fulfillment during peak demand periods, strengthening brand loyalty.

Benefits of Just-in-Time Fulfillment in Subscription Commerce

Just-in-time fulfillment in subscription commerce minimizes inventory holding costs by reducing the need for large storage spaces and decreasing the risk of overstock or obsolescence. This approach enhances cash flow management and allows businesses to respond quickly to customer preferences and trends, ensuring fresh, relevant products in every subscription box. Streamlined operations in just-in-time fulfillment also lead to faster order processing and improved customer satisfaction through timely deliveries.

Cost Considerations: Inventory Holding vs Just-in-Time

Inventory holding in subscription boxes incurs storage, insurance, and depreciation costs that can significantly increase overall expenses compared to just-in-time fulfillment, which minimizes these by procuring items only when orders are received. Just-in-time fulfillment reduces capital tied up in stock, enhances cash flow, and decreases the risk of unsold inventory, optimizing cost efficiency. However, inventory holding can benefit from bulk purchasing discounts, potentially lowering per-unit costs despite higher carrying expenses.

Customer Experience: Delivery Speed and Order Accuracy

Inventory holding ensures faster delivery and higher order accuracy by pre-stocking popular subscription box items, minimizing delays caused by supplier lead times. Just-in-time fulfillment reduces storage costs but risks slower delivery and potential stockouts, negatively impacting customer satisfaction. Optimizing between these methods enhances subscription box customer experience through timely shipments and precise order fulfillment.

Inventory Risk Management for Subscription Boxes

Inventory holding in subscription boxes helps maintain consistent product availability but increases risk of overstock and obsolescence, leading to higher storage costs. Just-in-time fulfillment minimizes inventory risk by aligning supply closely with demand, reducing excess stock and improving cash flow efficiency. Effective inventory risk management balances these approaches to ensure timely deliveries while optimizing warehouse space and minimizing lost revenue from unsold products.

Technology and Tools for Efficient Fulfillment

Inventory holding leverages warehouse management systems (WMS) and automated tracking technologies to maintain stock levels, ensuring faster order processing for subscription boxes. Just-in-time fulfillment relies on real-time demand forecasting tools, integrated supplier communication platforms, and AI-driven analytics to minimize storage costs and optimize supply chain responsiveness. Both strategies benefit from cloud-based inventory software and barcode scanning systems that enhance accuracy and streamline fulfillment workflows.

Scaling Your Subscription Box: Which Strategy Wins?

Scaling your subscription box business requires choosing between inventory holding and just-in-time fulfillment, each impacting costs and customer satisfaction differently. Inventory holding ensures faster delivery and bulk purchasing savings but increases storage expenses and risk of unsold stock. Just-in-time fulfillment reduces overhead by ordering products as needed, improving cash flow and adaptability, but may introduce delays affecting subscriber retention.

Choosing the Right Fulfillment Model for Your Business

Choosing the right fulfillment model for your subscription box business hinges on balancing inventory holding costs with order accuracy and delivery speed. Inventory holding allows bulk purchasing discounts and immediate shipment but increases storage expenses and risk of unsold stock. Just-in-time fulfillment minimizes inventory costs and reduces waste by sourcing products only after orders are placed, ideal for businesses prioritizing cash flow and customization.

Inventory holding vs Just-in-time fulfillment Infographic

bizdif.com

bizdif.com