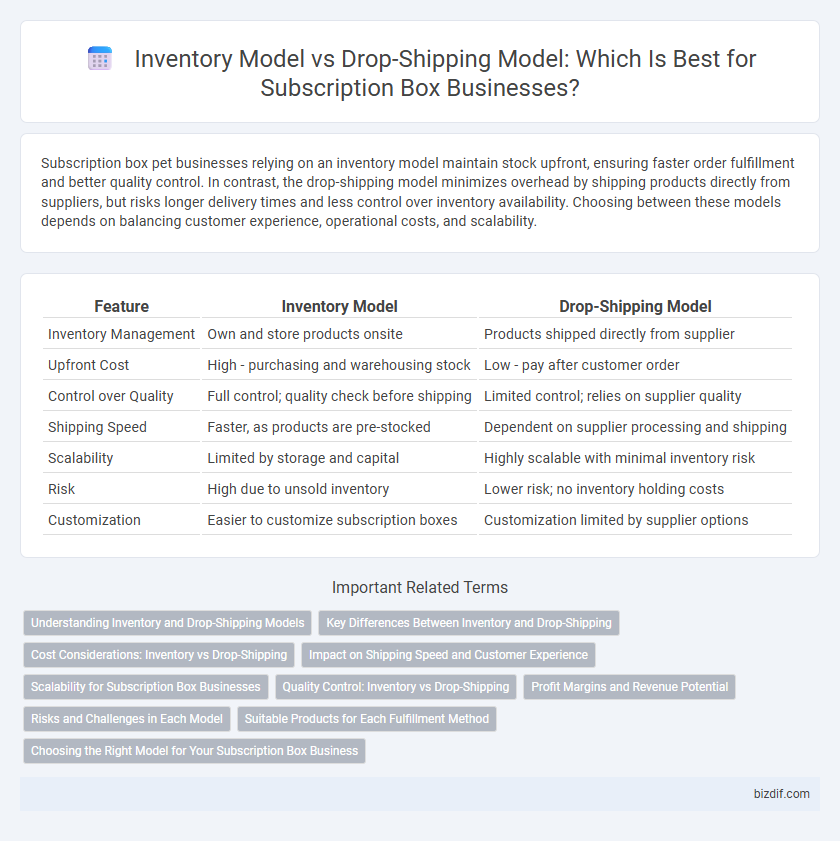

Subscription box pet businesses relying on an inventory model maintain stock upfront, ensuring faster order fulfillment and better quality control. In contrast, the drop-shipping model minimizes overhead by shipping products directly from suppliers, but risks longer delivery times and less control over inventory availability. Choosing between these models depends on balancing customer experience, operational costs, and scalability.

Table of Comparison

| Feature | Inventory Model | Drop-Shipping Model |

|---|---|---|

| Inventory Management | Own and store products onsite | Products shipped directly from supplier |

| Upfront Cost | High - purchasing and warehousing stock | Low - pay after customer order |

| Control over Quality | Full control; quality check before shipping | Limited control; relies on supplier quality |

| Shipping Speed | Faster, as products are pre-stocked | Dependent on supplier processing and shipping |

| Scalability | Limited by storage and capital | Highly scalable with minimal inventory risk |

| Risk | High due to unsold inventory | Lower risk; no inventory holding costs |

| Customization | Easier to customize subscription boxes | Customization limited by supplier options |

Understanding Inventory and Drop-Shipping Models

Inventory models require businesses to purchase, store, and manage products upfront, ensuring immediate availability but involving higher storage costs and risks of overstock. Drop-shipping models allow subscription box companies to partner with suppliers who directly ship products to customers, reducing inventory costs and minimizing risk but potentially increasing shipping times. Evaluating these models helps optimize supply chain efficiency and balance customer satisfaction with operational costs.

Key Differences Between Inventory and Drop-Shipping

The inventory model requires businesses to purchase, store, and manage stock upfront, resulting in higher initial capital investment and greater control over product quality and shipping times. In contrast, the drop-shipping model eliminates inventory holding by relying on third-party suppliers to fulfill orders directly, reducing overhead costs but increasing dependency on supplier reliability and longer fulfillment periods. Subscription box companies must weigh these trade-offs between inventory risks and operational flexibility when choosing their order fulfillment strategy.

Cost Considerations: Inventory vs Drop-Shipping

Inventory models require upfront investment in stock, incurring storage and warehousing costs, which can increase overall expenses but allow for better control over product availability and packaging quality. Drop-shipping minimizes inventory holding costs by directly shipping products from suppliers to customers, reducing overhead but potentially raising per-unit costs and limiting control over shipping times and product customization. Evaluating cost considerations between inventory and drop-shipping models is essential for subscription box businesses aiming to balance financial risk, customer experience, and operational efficiency.

Impact on Shipping Speed and Customer Experience

The inventory model stores products in-house, enabling faster order fulfillment and more reliable shipping schedules, which significantly enhances customer satisfaction. The drop-shipping model relies on third-party suppliers to ship directly to customers, often resulting in longer delivery times and less control over packaging and quality. Optimizing shipping speed through on-hand inventory typically leads to a more consistent and positive customer experience in subscription box services.

Scalability for Subscription Box Businesses

Inventory models offer subscription box businesses greater control over product quality and packaging, enabling consistent customer experiences crucial for brand loyalty. Scalability is often limited by upfront investment in inventory storage and potential overstock risks, which can strain cash flow during rapid growth phases. Drop-shipping models enhance scalability by eliminating inventory holding costs and allowing businesses to quickly expand product offerings without significant capital, though they may face challenges in quality control and longer shipping times impacting customer satisfaction.

Quality Control: Inventory vs Drop-Shipping

Inventory models offer enhanced quality control by allowing direct inspection and management of products before shipment, ensuring consistent customer satisfaction. Drop-shipping models rely on third-party suppliers, which can lead to variability in product quality due to limited oversight. Maintaining high-quality standards is more challenging in drop-shipping, making inventory models preferable for subscription boxes prioritizing reliability and brand trust.

Profit Margins and Revenue Potential

Subscription box businesses using inventory models often achieve higher profit margins due to bulk purchasing discounts and control over packaging, which lowers per-unit costs. In contrast, drop-shipping models reduce upfront inventory investment and risk but typically yield lower profit margins because of supplier fees and limited pricing flexibility. While inventory models maximize revenue potential through tailored pricing strategies and exclusive product sourcing, drop-shipping provides scalable revenue opportunities with less capital commitment but narrower profit channels.

Risks and Challenges in Each Model

Inventory models in subscription boxes require upfront investment and storage management, leading to risks like overstocking, product obsolescence, and cash flow constraints. Drop-shipping models eliminate inventory holding but pose challenges such as dependency on third-party suppliers for fulfillment, potential delays, inconsistent product quality, and lack of control over packaging experience. Each approach demands strategic risk mitigation to maintain customer satisfaction and operational efficiency in subscription services.

Suitable Products for Each Fulfillment Method

Subscription boxes featuring non-perishable, lightweight, and consistently in-demand products are best suited for inventory models, enabling bulk purchasing and streamlined order fulfillment. Drop-shipping models work well for customizable, high-value, or niche items that require minimal upfront investment and allow for flexible product offerings without inventory risk. Brands combining both methods can optimize cost efficiency and product variety by matching fulfillment strategies with specific product characteristics.

Choosing the Right Model for Your Subscription Box Business

Selecting the right inventory model for your subscription box business involves weighing control against flexibility. An inventory model provides better quality assurance and faster shipping by managing stock in-house, while a drop-shipping model reduces upfront costs and minimizes inventory risk by sourcing products directly from suppliers. Evaluating factors such as cash flow, storage capacity, and customer expectations is crucial to optimizing operational efficiency and ensuring long-term scalability.

Inventory model vs Drop-shipping model Infographic

bizdif.com

bizdif.com