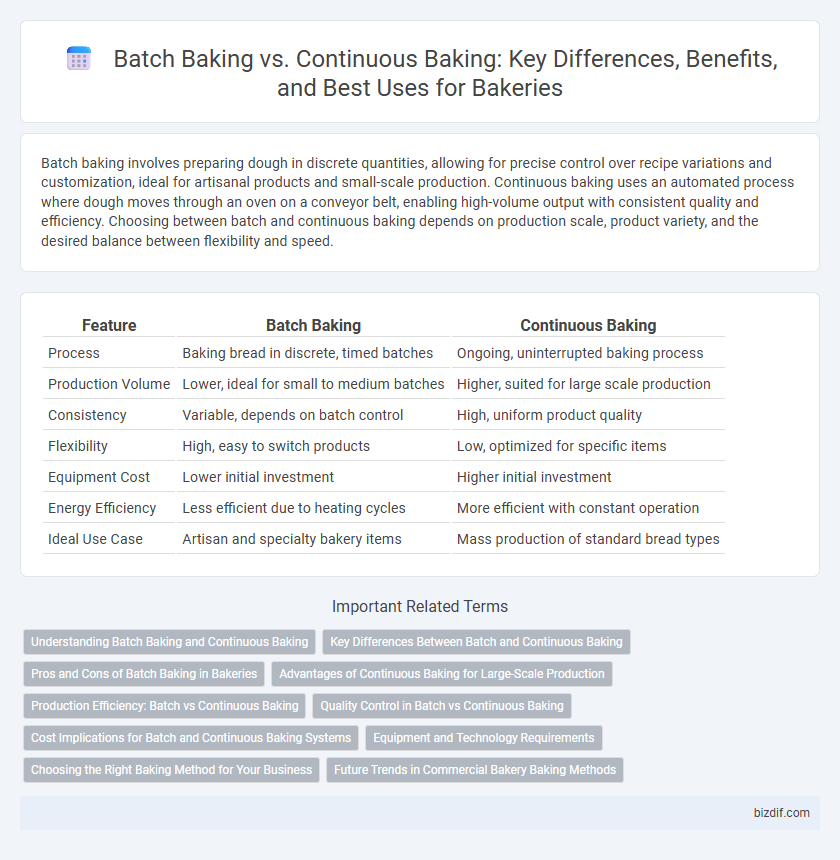

Batch baking involves preparing dough in discrete quantities, allowing for precise control over recipe variations and customization, ideal for artisanal products and small-scale production. Continuous baking uses an automated process where dough moves through an oven on a conveyor belt, enabling high-volume output with consistent quality and efficiency. Choosing between batch and continuous baking depends on production scale, product variety, and the desired balance between flexibility and speed.

Table of Comparison

| Feature | Batch Baking | Continuous Baking |

|---|---|---|

| Process | Baking bread in discrete, timed batches | Ongoing, uninterrupted baking process |

| Production Volume | Lower, ideal for small to medium batches | Higher, suited for large scale production |

| Consistency | Variable, depends on batch control | High, uniform product quality |

| Flexibility | High, easy to switch products | Low, optimized for specific items |

| Equipment Cost | Lower initial investment | Higher initial investment |

| Energy Efficiency | Less efficient due to heating cycles | More efficient with constant operation |

| Ideal Use Case | Artisan and specialty bakery items | Mass production of standard bread types |

Understanding Batch Baking and Continuous Baking

Batch baking involves preparing and baking dough in defined, separate quantities, allowing precise control over ingredient consistency and baking time for each batch. Continuous baking uses an ongoing process where dough moves steadily through the oven, enabling higher production rates and consistent quality over extended periods. Understanding the differences between batch and continuous baking helps optimize bakery operations based on production scale and product variety.

Key Differences Between Batch and Continuous Baking

Batch baking involves preparing and baking products in discrete groups, allowing for flexibility in recipe adjustments and varied product types, while continuous baking operates on a constant flow, maximizing production efficiency and consistency. Batch baking suits artisanal and small-scale operations requiring careful quality control, whereas continuous baking is ideal for large-scale industrial bakeries prioritizing volume and uniformity. Key differences include batch size, process control, production speed, and scalability, impacting product diversity and operational costs significantly.

Pros and Cons of Batch Baking in Bakeries

Batch baking in bakeries offers precise control over recipe variations and quality, ideal for artisan and specialty products, but it requires more labor and time compared to continuous baking systems. This method allows for smaller, customizable production runs, reducing waste and enabling flexibility in inventory management. However, batch baking may lead to inconsistent output volumes and increased production costs, limiting scalability for large-scale operations.

Advantages of Continuous Baking for Large-Scale Production

Continuous baking offers significant advantages for large-scale production by enabling consistent product quality through automated temperature and timing controls. This method increases efficiency with minimal downtime, resulting in higher throughput compared to batch baking. Additionally, continuous ovens reduce labor costs and energy consumption, optimizing overall operational expenses in industrial bakery settings.

Production Efficiency: Batch vs Continuous Baking

Batch baking offers flexibility and control over small to medium production runs but may result in longer downtime between batches, reducing overall production efficiency. Continuous baking maximizes throughput by maintaining an uninterrupted flow, ideal for large-scale operations requiring consistent product quality and faster output. The choice between batch and continuous baking depends on production volume, product variety, and desired efficiency metrics like output per hour and energy consumption.

Quality Control in Batch vs Continuous Baking

Batch baking allows for precise quality control by monitoring each batch individually, ensuring consistent texture, flavor, and appearance. Continuous baking relies on automated systems to maintain uniform temperature and baking conditions, which can reduce variability but may struggle with quick adjustments for product changes. The choice between batch and continuous baking impacts the ability to detect and correct quality issues promptly during production.

Cost Implications for Batch and Continuous Baking Systems

Batch baking incurs higher labor and energy costs due to frequent heating and cooling cycles, making it less cost-efficient for large-scale production. Continuous baking systems minimize downtime and maintain constant oven temperatures, significantly reducing energy consumption and labor expenses, which leads to lower overall operational costs. Investing in continuous baking technology offers economies of scale that optimize profitability for high-volume bakeries.

Equipment and Technology Requirements

Batch baking requires ovens that accommodate discrete, timed loads, often featuring adjustable racks and programmable controls for flexibility. Continuous baking systems utilize conveyor ovens with integrated heating technologies and automated dough handling to ensure uninterrupted production. Both methods demand specialized equipment tailored to production scale, with continuous baking favoring advanced automation and consistency controls.

Choosing the Right Baking Method for Your Business

Batch baking offers precise control over product quality and variation, making it ideal for artisan bakeries and small-scale operations with diverse product lines. Continuous baking suits high-volume production, ensuring consistent output and efficiency for large commercial bakeries focused on standardized products. Selecting the right method depends on your bakery's scale, product variety, and production goals to optimize quality, cost, and operational efficiency.

Future Trends in Commercial Bakery Baking Methods

Batch baking involves producing baked goods in discrete quantities, offering flexibility for varied product lines, while continuous baking uses automated conveyor systems for steady, high-volume output. Future trends in commercial bakery methods emphasize integrating AI-driven controls and energy-efficient technologies to optimize baking times and improve product consistency. Innovations like real-time quality monitoring and sustainable ovens are set to transform both batch and continuous baking toward greater efficiency and reduced environmental impact.

Batch Baking vs Continuous Baking Infographic

bizdif.com

bizdif.com