Small batch production in a bakery ensures fresher products with greater attention to detail and higher quality control compared to mass production. This method allows for unique, artisanal flavors and customization that large-scale operations often cannot replicate. Although mass production yields consistent output at a lower cost, it may sacrifice the authenticity and handcrafted touch prized by discerning customers.

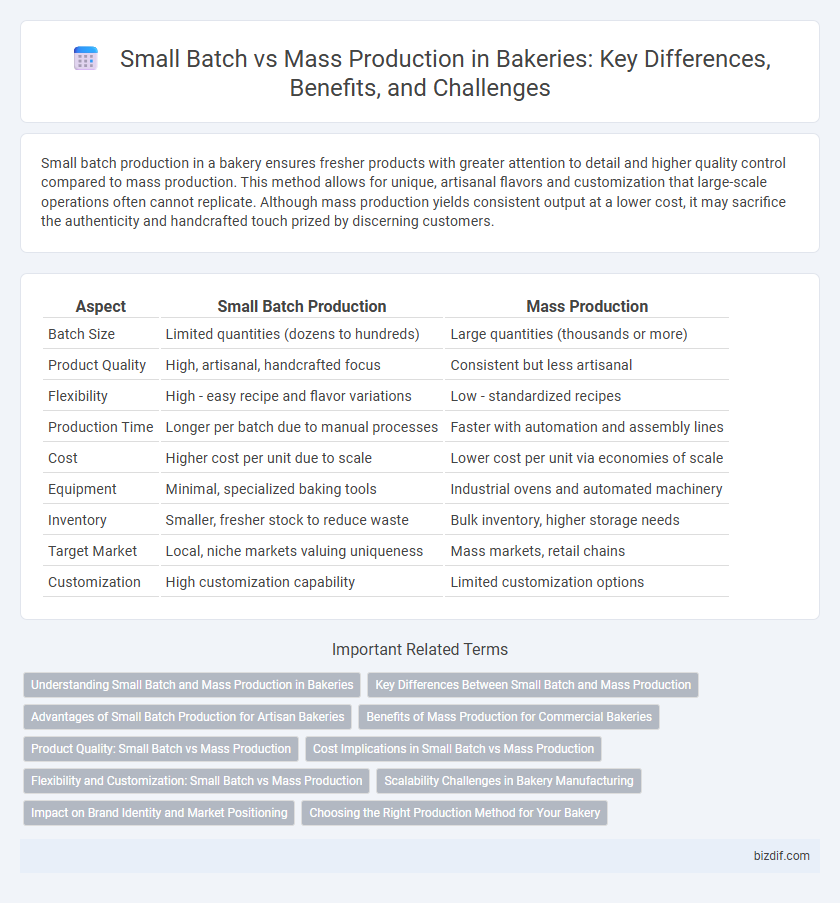

Table of Comparison

| Aspect | Small Batch Production | Mass Production |

|---|---|---|

| Batch Size | Limited quantities (dozens to hundreds) | Large quantities (thousands or more) |

| Product Quality | High, artisanal, handcrafted focus | Consistent but less artisanal |

| Flexibility | High - easy recipe and flavor variations | Low - standardized recipes |

| Production Time | Longer per batch due to manual processes | Faster with automation and assembly lines |

| Cost | Higher cost per unit due to scale | Lower cost per unit via economies of scale |

| Equipment | Minimal, specialized baking tools | Industrial ovens and automated machinery |

| Inventory | Smaller, fresher stock to reduce waste | Bulk inventory, higher storage needs |

| Target Market | Local, niche markets valuing uniqueness | Mass markets, retail chains |

| Customization | High customization capability | Limited customization options |

Understanding Small Batch and Mass Production in Bakeries

Small batch production in bakeries emphasizes artisanal quality, allowing for precise control over ingredients and baking processes that enhance flavor and texture. Mass production prioritizes efficiency and volume, utilizing standardized recipes and automated equipment to meet high consumer demand rapidly. Understanding these methods helps bakers balance creativity with scalability, ensuring product consistency while maintaining distinctiveness.

Key Differences Between Small Batch and Mass Production

Small batch production in bakeries emphasizes artisanal quality, using limited ingredients to produce unique, fresh products with higher customization and less waste. Mass production focuses on efficiency and volume, utilizing automated processes to bake large quantities with consistent taste and longer shelf life. Key differences include production scale, product variety, quality control, and flexibility, impacting cost, customer satisfaction, and market reach.

Advantages of Small Batch Production for Artisan Bakeries

Small batch production allows artisan bakeries to maintain higher quality control and consistency in their baked goods by closely monitoring each batch. This approach enables the use of premium, often locally sourced ingredients, enhancing flavor and freshness which attracts discerning customers. Small batch production also fosters creativity and flexibility in recipe experimentation, helping artisan bakeries differentiate themselves in a competitive market.

Benefits of Mass Production for Commercial Bakeries

Mass production in commercial bakeries enables consistent product quality and faster output, meeting high consumer demand efficiently. Automated processes reduce labor costs and minimize human error, resulting in improved profitability and scalability. Bulk ingredient purchasing further lowers expenses, enhancing overall operational efficiency for large-scale bakery businesses.

Product Quality: Small Batch vs Mass Production

Small batch production in bakeries ensures higher product quality through meticulous attention to ingredient selection and baking techniques, resulting in fresher, more flavorful goods. Mass production often compromises quality due to standardized processes and longer shelf storage, which can affect texture and taste consistency. Small batches also allow for better quality control and customization, enhancing overall customer satisfaction with each product.

Cost Implications in Small Batch vs Mass Production

Small batch production in bakery typically incurs higher per-unit costs due to frequent changeovers, manual processes, and lower economies of scale, resulting in increased labor and ingredient expenses. In contrast, mass production benefits from bulk purchasing, automated equipment, and streamlined processes, significantly reducing cost per unit and increasing profit margins. However, small batch production allows for greater product customization and quality control, often justifying the higher costs for artisanal or specialty baked goods.

Flexibility and Customization: Small Batch vs Mass Production

Small batch production in bakeries allows for greater flexibility and customization, enabling bakers to experiment with unique recipes and tailor products to specific customer preferences. In contrast, mass production prioritizes uniformity and scale, limiting the ability to adjust flavors, ingredients, or designs for individual orders. This flexibility in small batch approaches supports artisan quality and niche market demands, while mass production excels in meeting high-volume, consistent supply needs.

Scalability Challenges in Bakery Manufacturing

Small batch production in bakery manufacturing offers flexibility and quality control but faces scalability challenges such as higher labor costs and limited output capacity. Mass production enables large-scale output and consistent product uniformity but requires significant investment in automation and can reduce artisanal characteristics. Balancing these approaches demands adopting scalable processes that maintain product integrity while optimizing efficiency to meet growing market demand.

Impact on Brand Identity and Market Positioning

Small batch production in bakeries enhances brand identity by emphasizing artisanal quality, unique flavors, and limited availability, which appeals to niche markets seeking authenticity. Mass production supports broader market positioning through consistent product availability, competitive pricing, and widespread brand recognition, catering to high-volume demand. The choice between these methods directly shapes consumer perception, influencing loyalty and market differentiation.

Choosing the Right Production Method for Your Bakery

Small batch production in bakeries ensures higher quality, fresher products, and greater flexibility to customize recipes, ideal for artisan or specialty bakeries targeting niche markets. Mass production suits large-scale bakeries aiming for consistent output, cost efficiency, and meeting high consumer demand with standardized products. Evaluating bakery size, customer expectations, ingredient sourcing, and equipment investment helps determine the best production method to optimize operational efficiency and product appeal.

Small Batch Production vs Mass Production Infographic

bizdif.com

bizdif.com