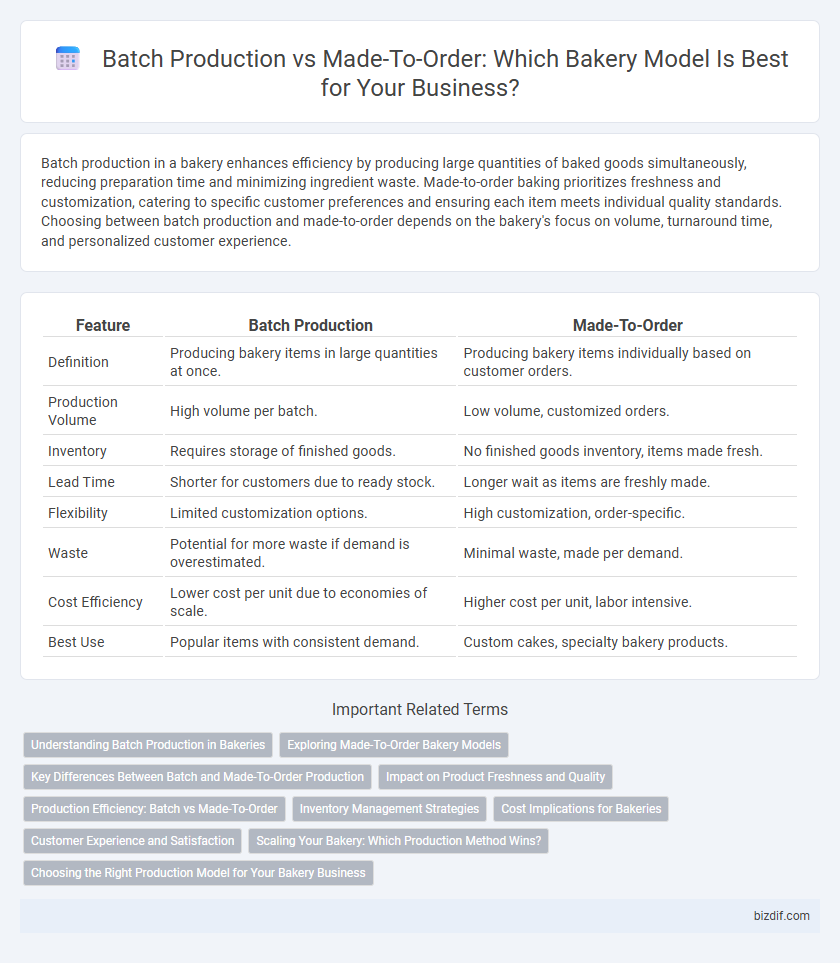

Batch production in a bakery enhances efficiency by producing large quantities of baked goods simultaneously, reducing preparation time and minimizing ingredient waste. Made-to-order baking prioritizes freshness and customization, catering to specific customer preferences and ensuring each item meets individual quality standards. Choosing between batch production and made-to-order depends on the bakery's focus on volume, turnaround time, and personalized customer experience.

Table of Comparison

| Feature | Batch Production | Made-To-Order |

|---|---|---|

| Definition | Producing bakery items in large quantities at once. | Producing bakery items individually based on customer orders. |

| Production Volume | High volume per batch. | Low volume, customized orders. |

| Inventory | Requires storage of finished goods. | No finished goods inventory, items made fresh. |

| Lead Time | Shorter for customers due to ready stock. | Longer wait as items are freshly made. |

| Flexibility | Limited customization options. | High customization, order-specific. |

| Waste | Potential for more waste if demand is overestimated. | Minimal waste, made per demand. |

| Cost Efficiency | Lower cost per unit due to economies of scale. | Higher cost per unit, labor intensive. |

| Best Use | Popular items with consistent demand. | Custom cakes, specialty bakery products. |

Understanding Batch Production in Bakeries

Batch production in bakeries involves producing a set quantity of baked goods simultaneously, optimizing efficiency and consistency by using standardized recipes and processes. This method allows for better inventory management, reduced waste, and faster turnaround times compared to made-to-order baking. Bakeries employing batch production can scale output to meet demand patterns while maintaining product quality and minimizing labor costs.

Exploring Made-To-Order Bakery Models

Made-to-order bakery models prioritize fresh, customized products by baking goods only after receiving customer orders, reducing waste and enhancing product quality. This approach allows bakeries to tailor recipes and accommodate dietary preferences, increasing customer satisfaction and loyalty. Unlike batch production, which emphasizes volume and efficiency, made-to-order prioritizes flexibility and freshness, aligning with demand-driven production strategies.

Key Differences Between Batch and Made-To-Order Production

Batch production in bakeries involves creating large quantities of standardized products such as bread or cookies in groups, maximizing efficiency and reducing costs through economies of scale. Made-to-order production focuses on customizing baked goods according to specific customer requests, offering tailored products like personalized cakes or specialty pastries with greater freshness and uniqueness. Key differences between these methods include production volume, customization level, and lead time, with batch production emphasizing uniformity and speed, while made-to-order prioritizes customer preferences and flexibility.

Impact on Product Freshness and Quality

Batch production in bakeries allows for consistent quality control and efficient use of ingredients, but may lead to slight variations in product freshness as items are made in large quantities ahead of demand. Made-to-order baking ensures maximum product freshness and customization by preparing items only after receiving customer orders, promoting optimal texture and flavor with minimal holding time. However, this method can increase production time and limit volume, affecting overall operational efficiency compared to batch production.

Production Efficiency: Batch vs Made-To-Order

Batch production in bakeries streamlines output by producing large quantities of standardized products, optimizing oven usage and ingredient preparation to minimize downtime. Made-to-order production tailors each item to customer specifications, reducing inventory waste but potentially increasing production time and labor costs. Efficiency in batch production generally surpasses made-to-order models due to economies of scale and predictable demand patterns.

Inventory Management Strategies

Batch production in bakery allows for efficient ingredient utilization and standardized inventory control by producing large quantities of items simultaneously, reducing waste and storage costs. Made-to-order baking relies on precise demand forecasting and real-time inventory tracking to minimize raw material excess and ensure product freshness. Implementing a hybrid inventory management strategy can optimize supply levels, balancing bulk ingredient purchases with flexible production schedules to meet customer demand while preventing overstocking.

Cost Implications for Bakeries

Batch production in bakeries reduces unit costs by enabling bulk purchasing of ingredients and efficient use of oven time, resulting in economies of scale. Made-to-order production often incurs higher costs due to smaller ingredient quantities, increased preparation time, and variability in demand leading to potential waste. Choosing between the two impacts overall profitability, with batch production favoring cost efficiency and made-to-order supporting customization at a premium price.

Customer Experience and Satisfaction

Batch production in bakeries ensures consistent product availability and uniform quality, enhancing customer satisfaction through reliability and quick service. Made-to-order baking offers personalized products, catering to specific customer preferences, which increases perceived value and engagement. Balancing batch production's efficiency with made-to-order's customization optimizes overall customer experience and loyalty.

Scaling Your Bakery: Which Production Method Wins?

Batch production allows bakeries to efficiently scale by producing large quantities of standardized goods, reducing per-unit costs and optimizing ingredient usage. Made-to-order baking offers customization and fresher products but limits output and increases labor intensity, posing challenges for large-scale operations. Choosing batch production is advantageous for consistent demand and scaling, while made-to-order suits niche markets seeking personalized baked goods.

Choosing the Right Production Model for Your Bakery Business

Batch production in a bakery maximizes efficiency by producing large quantities of baked goods at once, reducing ingredient waste and lowering labor costs per unit. Made-to-order focuses on customization and freshness, catering to specific customer demands and minimizing inventory storage needs. Selecting the appropriate production model depends on your bakery's target market, product variety, and operational capacity to balance quality, cost, and customer satisfaction.

Batch Production vs Made-To-Order Infographic

bizdif.com

bizdif.com