Centralized production in bakeries enables consistent quality control and cost efficiency by consolidating baking processes in a single location. Decentralized production allows for fresher products and quicker delivery to local markets, enhancing customer satisfaction. Choosing the right model depends on factors like scale, target market, and distribution logistics.

Table of Comparison

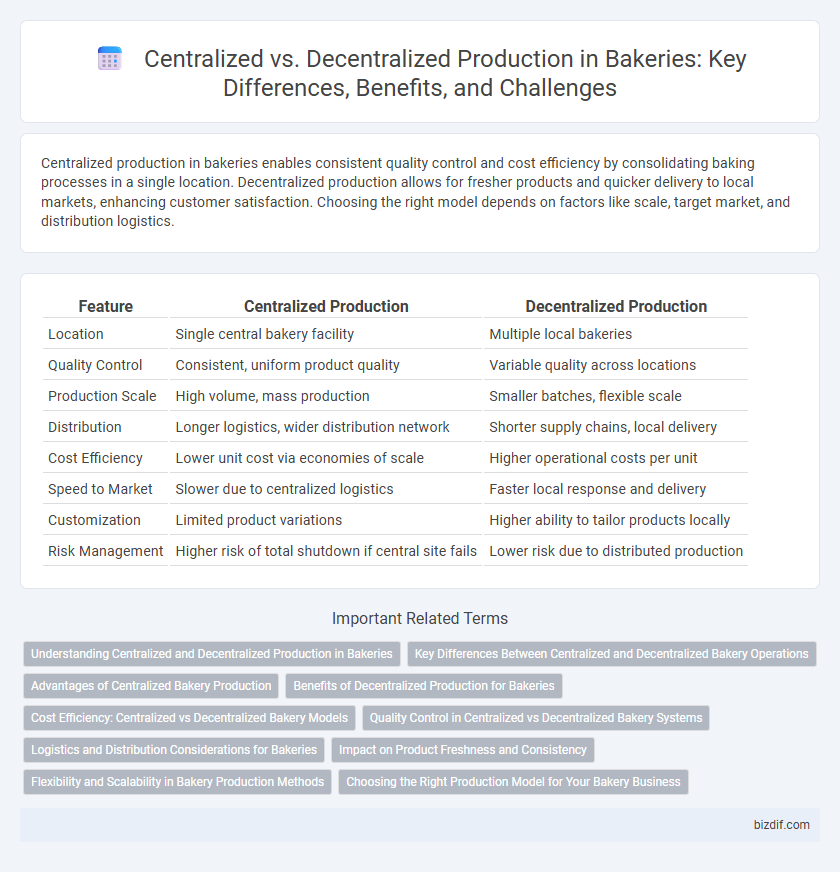

| Feature | Centralized Production | Decentralized Production |

|---|---|---|

| Location | Single central bakery facility | Multiple local bakeries |

| Quality Control | Consistent, uniform product quality | Variable quality across locations |

| Production Scale | High volume, mass production | Smaller batches, flexible scale |

| Distribution | Longer logistics, wider distribution network | Shorter supply chains, local delivery |

| Cost Efficiency | Lower unit cost via economies of scale | Higher operational costs per unit |

| Speed to Market | Slower due to centralized logistics | Faster local response and delivery |

| Customization | Limited product variations | Higher ability to tailor products locally |

| Risk Management | Higher risk of total shutdown if central site fails | Lower risk due to distributed production |

Understanding Centralized and Decentralized Production in Bakeries

Centralized production in bakeries consolidates baking processes in a single facility, enhancing consistency and reducing costs through economies of scale, while decentralized production involves multiple smaller sites closer to customers for fresher products and quicker delivery. Centralized bakeries benefit from streamlined operations and bulk purchasing, yet may face challenges in distribution and freshness maintenance. Decentralized bakeries improve responsiveness to local demand and customization but often incur higher operational expenses due to duplicated equipment and labor.

Key Differences Between Centralized and Decentralized Bakery Operations

Centralized bakery operations consolidate baking processes and distribution in a single large facility, ensuring consistent product quality and efficient resource utilization. Decentralized bakery operations involve multiple smaller production sites closer to customers, enabling faster delivery and enhanced customization to local tastes. Centralized systems benefit from economies of scale, while decentralized setups offer greater flexibility and responsiveness to market demand.

Advantages of Centralized Bakery Production

Centralized bakery production improves consistency and product quality by maintaining uniform baking processes and ingredient control across all batches. It reduces operational costs through bulk purchasing and streamlined labor, increasing overall efficiency and profitability. Centralized facilities also simplify inventory management and quality assurance, enabling faster innovation and scaling of new product lines.

Benefits of Decentralized Production for Bakeries

Decentralized production in bakeries enhances flexibility by allowing multiple small-scale ovens to operate closer to target markets, reducing delivery times and preserving product freshness. This approach lowers transportation costs and minimizes risks related to equipment failure or supply chain disruptions, as individual units can function independently. Increased responsiveness to local tastes and demand fluctuations also improves customer satisfaction and supports sustainable growth.

Cost Efficiency: Centralized vs Decentralized Bakery Models

Centralized bakery production leverages economies of scale by consolidating baking processes in a single location, significantly reducing labor, equipment, and ingredient costs per unit. Decentralized bakery models incur higher operational expenses due to multiple production sites requiring duplicated resources, but they benefit from localized freshness and reduced distribution costs. Cost-efficiency in centralized systems is optimized through bulk purchasing and streamlined workflows, while decentralized setups prioritize market responsiveness at the expense of higher overhead.

Quality Control in Centralized vs Decentralized Bakery Systems

Centralized bakery production allows for stringent quality control through standardized processes, consistent ingredient sourcing, and specialized equipment, ensuring product uniformity and compliance with safety regulations. Decentralized bakery systems may face challenges maintaining consistent quality due to variations in local ingredient availability, differing staff expertise, and less centralized oversight. Implementing digitized quality monitoring tools in decentralized bakeries can help bridge the quality control gap by enabling real-time data collection and analysis across multiple locations.

Logistics and Distribution Considerations for Bakeries

Centralized production in bakeries streamlines logistics by consolidating baking processes in a single facility, reducing inventory complexity and enabling bulk transportation efficiencies. Decentralized production requires robust distribution networks to ensure fresh product delivery from multiple locations, increasing logistical challenges and transportation costs. Strategic location of baking sites near key markets decreases delivery times and preserves product quality in both production models.

Impact on Product Freshness and Consistency

Centralized production in bakeries ensures consistent product quality by using standardized recipes and equipment across multiple outlets, but it may affect freshness due to transportation and storage time. Decentralized production allows bakeries to bake goods closer to the point of sale, enhancing freshness and immediate availability for customers. Balancing freshness and consistency depends on factors like distribution logistics, shelf life of baked goods, and customer expectations for quality.

Flexibility and Scalability in Bakery Production Methods

Centralized bakery production streamlines operations by consolidating baking processes in a single facility, enhancing scalability through standardized systems and bulk ingredient procurement. Decentralized production offers greater flexibility, allowing bakeries to customize products and respond quickly to local demand fluctuations by operating multiple smaller kitchens. Balancing both methods enables bakeries to efficiently scale output while maintaining adaptability to regional preferences and market changes.

Choosing the Right Production Model for Your Bakery Business

Centralized production in a bakery allows for consistent quality control and streamlined ingredient sourcing, making it ideal for businesses aiming to scale efficiently. Decentralized production offers flexibility and faster delivery to local markets, which benefits bakeries targeting diverse customer preferences and customization. Selecting the right model depends on factors like target market size, product variety, and logistical capabilities to optimize cost and customer satisfaction.

Centralized production vs Decentralized production Infographic

bizdif.com

bizdif.com