Small-batch roasting in bakery ensures greater control over the quality and flavor of coffee beans, producing a fresher and more aromatic cup ideal for pairing with baked goods. Mass production, while efficient and cost-effective, often sacrifices the nuanced flavors that come from carefully monitored roasting. Prioritizing small-batch roasting enhances the overall customer experience with a distinct, artisanal touch rarely found in mass-produced coffee options.

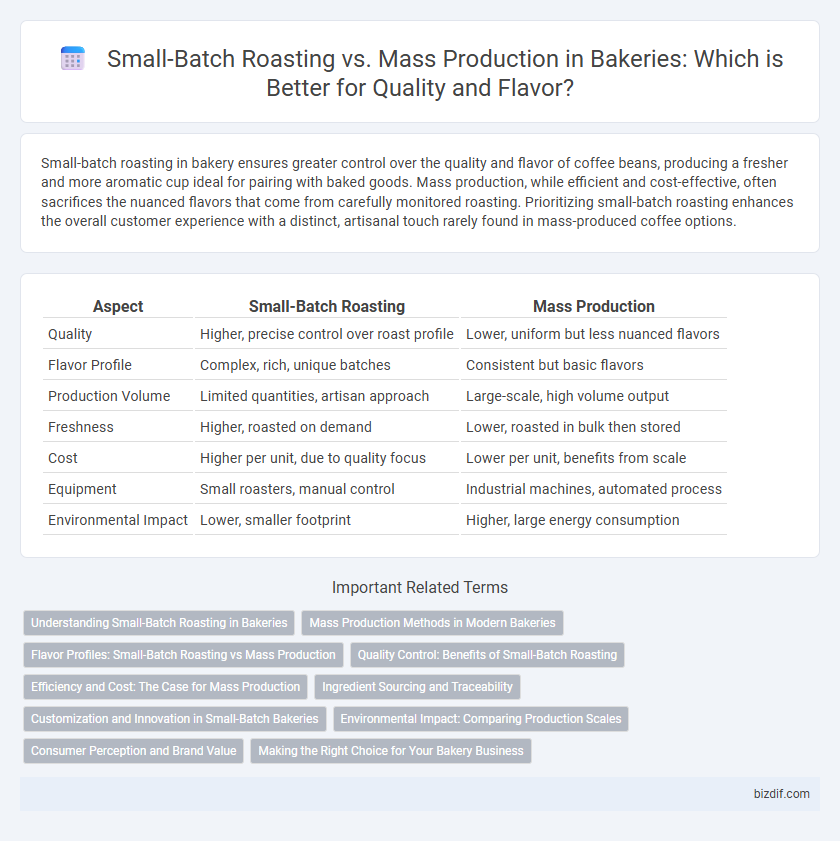

Table of Comparison

| Aspect | Small-Batch Roasting | Mass Production |

|---|---|---|

| Quality | Higher, precise control over roast profile | Lower, uniform but less nuanced flavors |

| Flavor Profile | Complex, rich, unique batches | Consistent but basic flavors |

| Production Volume | Limited quantities, artisan approach | Large-scale, high volume output |

| Freshness | Higher, roasted on demand | Lower, roasted in bulk then stored |

| Cost | Higher per unit, due to quality focus | Lower per unit, benefits from scale |

| Equipment | Small roasters, manual control | Industrial machines, automated process |

| Environmental Impact | Lower, smaller footprint | Higher, large energy consumption |

Understanding Small-Batch Roasting in Bakeries

Small-batch roasting in bakeries involves carefully roasting limited quantities of coffee beans or specialty grains to ensure optimal freshness and flavor complexity, which significantly enhances the overall product quality. This method allows for precise control over roasting parameters, resulting in a unique taste profile that mass production techniques cannot replicate. Emphasizing artisanal craftsmanship, small-batch roasting supports sustainable sourcing and caters to discerning customers seeking premium bakery experiences.

Mass Production Methods in Modern Bakeries

Mass production methods in modern bakeries employ automated equipment and conveyor systems to efficiently produce large quantities of baked goods with consistent quality. These techniques leverage precise temperature control, standardized ingredient mixing, and high-speed ovens to optimize output and reduce labor costs. By utilizing scalable production lines, mass production meets growing consumer demand while maintaining product uniformity across distribution channels.

Flavor Profiles: Small-Batch Roasting vs Mass Production

Small-batch roasting enhances flavor profiles by allowing precise control over roasting times and temperatures, resulting in richer, more complex coffee notes with pronounced acidity and aroma. Mass production often sacrifices these nuanced flavors due to uniform roasting processes designed for consistency and volume, leading to a flatter, more generic taste. Bakers and coffee artisans who prioritize small-batch roasting achieve a distinctive cup quality that highlights unique bean characteristics and terroir.

Quality Control: Benefits of Small-Batch Roasting

Small-batch roasting allows for precise quality control by roasting limited coffee quantities, ensuring consistent flavor profiles and freshness. This method enables bakers to monitor each batch closely, reducing the risk of defects and enhancing product uniqueness. In contrast, mass production often sacrifices attention to detail, leading to variability and diminished overall quality in bakery offerings.

Efficiency and Cost: The Case for Mass Production

Mass production in bakery roasting significantly boosts efficiency by utilizing automated machinery that processes large quantities of dough or ingredients swiftly, reducing labor costs. Economies of scale enable mass production to lower raw material expenses and energy consumption per unit, resulting in competitive pricing for consumers. While small-batch roasting offers artisanal quality, mass production excels in cost-effectiveness and output consistency essential for meeting high market demand.

Ingredient Sourcing and Traceability

Small-batch roasting in bakeries ensures meticulous ingredient sourcing with a focus on traceability, often partnering directly with local farmers to guarantee fresh, high-quality grains and unique flavor profiles. Mass production typically relies on bulk ingredient suppliers, which can limit transparency and reduce the ability to track the origin and quality of raw materials. This difference significantly impacts product freshness, flavor consistency, and consumer trust in ingredient authenticity.

Customization and Innovation in Small-Batch Bakeries

Small-batch roasting in bakeries allows for greater customization, enabling bakers to experiment with unique blends, flavors, and ingredient combinations tailored to specific customer preferences. This approach fosters innovation by facilitating creative recipes and small-scale testing, leading to distinctive products that stand out from mass-produced baked goods. Small-batch bakeries can quickly adapt to emerging trends, ensuring fresher, higher-quality items with a personal touch that mass production often lacks.

Environmental Impact: Comparing Production Scales

Small-batch roasting in bakeries minimizes environmental impact through reduced energy consumption and lower carbon emissions compared to mass production methods, which often involve large-scale equipment and resource-intensive processes. Small-batch operations prioritize sustainable sourcing and waste reduction, enhancing the overall ecological footprint. Mass production, while efficient for meeting high demand, typically generates higher levels of waste and environmental degradation due to its scale and mechanized processes.

Consumer Perception and Brand Value

Small-batch roasting in bakeries is perceived by consumers as a marker of artisanal quality and freshness, often enhancing the brand's premium value and customer loyalty. Mass production, while efficient, can lead to perceptions of lower quality and diminished uniqueness, potentially weakening brand differentiation. Emphasizing small-batch techniques aligns with growing consumer preferences for authenticity and handcrafted products, driving higher perceived value.

Making the Right Choice for Your Bakery Business

Small-batch roasting enables bakeries to maintain superior coffee bean freshness and flavor consistency, essential for pairing with high-quality baked goods and enhancing customer experience. Mass production offers cost efficiencies and scalability but may compromise the nuanced taste profiles that distinguish artisanal baked products. Selecting the right roast method depends on your bakery's brand identity, target market preferences, and commitment to product excellence.

Small-batch roasting vs Mass production Infographic

bizdif.com

bizdif.com