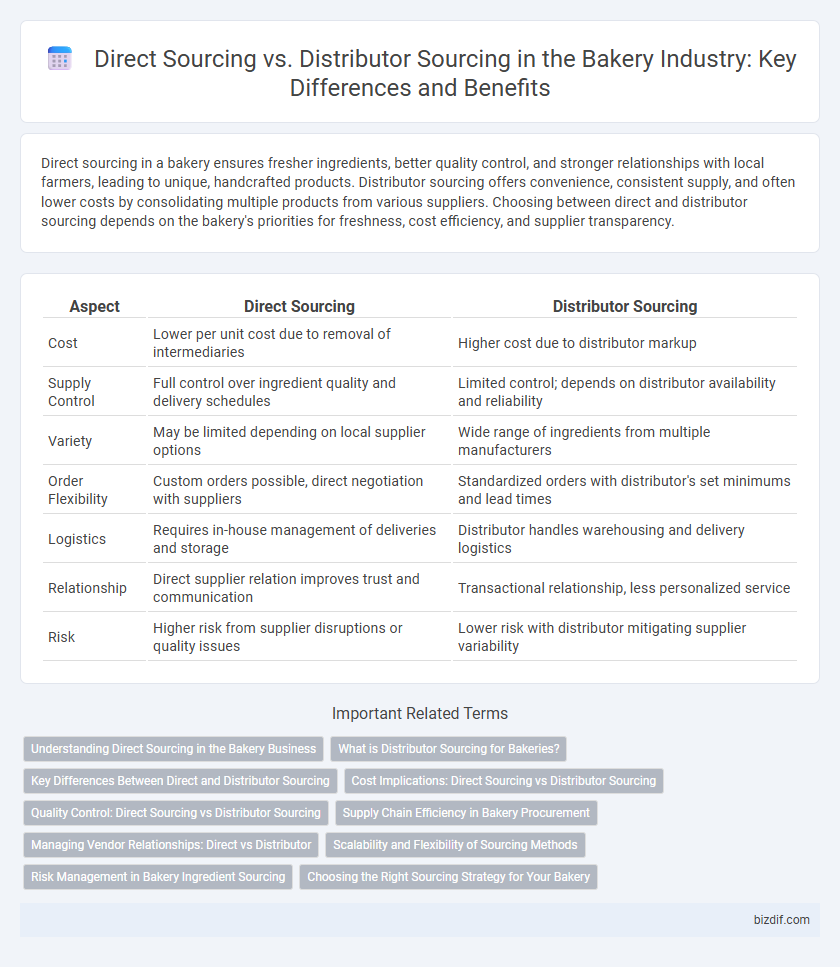

Direct sourcing in a bakery ensures fresher ingredients, better quality control, and stronger relationships with local farmers, leading to unique, handcrafted products. Distributor sourcing offers convenience, consistent supply, and often lower costs by consolidating multiple products from various suppliers. Choosing between direct and distributor sourcing depends on the bakery's priorities for freshness, cost efficiency, and supplier transparency.

Table of Comparison

| Aspect | Direct Sourcing | Distributor Sourcing |

|---|---|---|

| Cost | Lower per unit cost due to removal of intermediaries | Higher cost due to distributor markup |

| Supply Control | Full control over ingredient quality and delivery schedules | Limited control; depends on distributor availability and reliability |

| Variety | May be limited depending on local supplier options | Wide range of ingredients from multiple manufacturers |

| Order Flexibility | Custom orders possible, direct negotiation with suppliers | Standardized orders with distributor's set minimums and lead times |

| Logistics | Requires in-house management of deliveries and storage | Distributor handles warehousing and delivery logistics |

| Relationship | Direct supplier relation improves trust and communication | Transactional relationship, less personalized service |

| Risk | Higher risk from supplier disruptions or quality issues | Lower risk with distributor mitigating supplier variability |

Understanding Direct Sourcing in the Bakery Business

Direct sourcing in the bakery business involves procuring raw ingredients such as flour, sugar, and yeast directly from farmers or manufacturers, ensuring fresher quality and greater control over supply chains. This approach reduces intermediaries, leading to cost savings and enhanced transparency in ingredient origin, which is crucial for maintaining product consistency and meeting customer expectations. Emphasizing direct relationships with suppliers enables bakeries to customize orders, secure sustainable sourcing, and respond swiftly to market trends or ingredient shortages.

What is Distributor Sourcing for Bakeries?

Distributor sourcing for bakeries involves purchasing ingredients and supplies through a third-party distributor who consolidates products from multiple manufacturers. This approach offers convenience, access to a wide range of products, and often provides better supply chain reliability compared to direct sourcing. Distributors typically negotiate bulk pricing and manage inventory, allowing bakeries to focus on production and customer service.

Key Differences Between Direct and Distributor Sourcing

Direct sourcing in bakery supplies involves purchasing ingredients and materials straight from manufacturers or farmers, enabling better control over quality and pricing. Distributor sourcing, conversely, offers convenience through bulk purchasing, a wider product selection, and streamlined logistics, but often at higher costs and less product transparency. Choosing between these methods depends on the bakery's scale, budget, and need for product customization.

Cost Implications: Direct Sourcing vs Distributor Sourcing

Direct sourcing in bakery operations often reduces costs by eliminating distributor markups and allowing bulk purchasing, leading to lower per-unit expenses and higher profit margins. Distributor sourcing, while potentially increasing costs due to added fees and smaller order volumes, offers convenience, faster delivery, and a wider product selection that can offset the price premium. Careful analysis of order frequency, storage capacity, and supplier relationships is essential to optimize cost efficiency in ingredient procurement.

Quality Control: Direct Sourcing vs Distributor Sourcing

Direct sourcing in bakery supply chains enables tighter quality control by allowing bakeries to inspect raw materials firsthand and establish direct relationships with suppliers, ensuring freshness and consistency. Distributor sourcing often involves less transparency, increasing the risk of variability in ingredient quality due to multiple handling stages. Maintaining strict quality standards is more feasible when bakeries source directly, minimizing contamination and meeting specific product specifications.

Supply Chain Efficiency in Bakery Procurement

Direct sourcing in bakery procurement streamlines supply chain efficiency by eliminating intermediaries, ensuring fresher ingredients and faster delivery times critical for perishable goods. Distributor sourcing offers broader access to diverse bakery supplies but may introduce delays and variability in product quality due to additional handling. Optimizing bakery supply chains involves balancing direct relationships with ingredient producers and reliable distributors to maintain consistent inventory levels and reduce shortages.

Managing Vendor Relationships: Direct vs Distributor

Managing vendor relationships in bakery supply chains differs significantly between direct sourcing and distributor sourcing. Direct sourcing allows bakeries to establish close, transparent partnerships with ingredient producers, ensuring consistent quality and timely customization. Distributor sourcing offers streamlined communication with a single point of contact managing multiple suppliers, reducing administrative burden but potentially limiting direct influence over individual vendor performance.

Scalability and Flexibility of Sourcing Methods

Direct sourcing in bakery operations enhances scalability by allowing personalized control over ingredient quality and supply volume, facilitating rapid adjustments to demand fluctuations. Distributor sourcing offers greater flexibility through access to a wide variety of products and simplified procurement processes, enabling bakeries to diversify offerings without extensive supplier management. Balancing both methods can optimize supply chain responsiveness and cost-efficiency in expanding bakery businesses.

Risk Management in Bakery Ingredient Sourcing

Direct sourcing of bakery ingredients reduces the risk of supply chain disruptions by enabling closer relationships with farmers and producers, ensuring consistent quality and traceability. Distributor sourcing provides flexibility and access to a broader range of products but may increase exposure to variability in ingredient quality and delivery delays. Effective risk management in bakery ingredient sourcing balances direct supplier partnerships with distributor networks to optimize cost, quality, and reliability.

Choosing the Right Sourcing Strategy for Your Bakery

Direct sourcing allows bakeries to secure fresh, high-quality ingredients directly from farmers or producers, enhancing product authenticity and traceability. Distributor sourcing offers convenience and a wide range of products with reliable delivery schedules, reducing procurement complexity. Selecting the right sourcing strategy depends on your bakery's scale, budget, and commitment to ingredient quality and supply chain transparency.

Direct Sourcing vs Distributor Sourcing Infographic

bizdif.com

bizdif.com