Manual mixing provides bakers with tactile control over dough consistency, allowing for adjustments based on texture and ingredient integration. Automated mixing ensures uniformity and saves time, delivering consistent results perfect for large-scale production. Choosing between the two depends on the bakery's scale, desired dough characteristics, and operational efficiency.

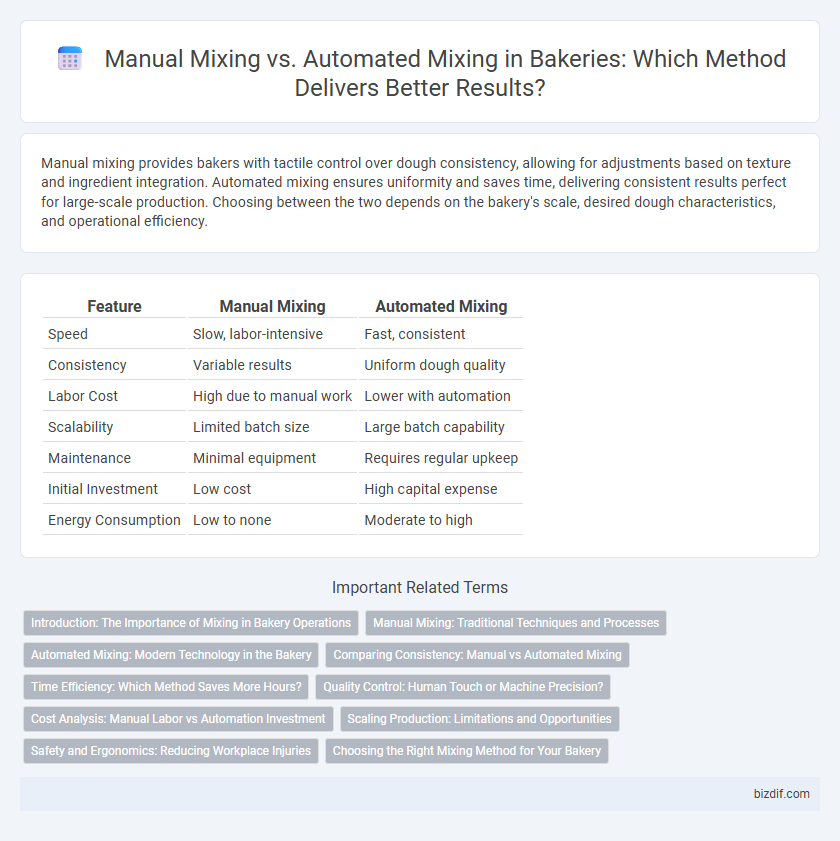

Table of Comparison

| Feature | Manual Mixing | Automated Mixing |

|---|---|---|

| Speed | Slow, labor-intensive | Fast, consistent |

| Consistency | Variable results | Uniform dough quality |

| Labor Cost | High due to manual work | Lower with automation |

| Scalability | Limited batch size | Large batch capability |

| Maintenance | Minimal equipment | Requires regular upkeep |

| Initial Investment | Low cost | High capital expense |

| Energy Consumption | Low to none | Moderate to high |

Introduction: The Importance of Mixing in Bakery Operations

Mixing is a critical step in bakery operations that directly influences dough consistency, texture, and overall product quality. Manual mixing allows precise control over ingredient incorporation but can be time-consuming and inconsistent for large batches. Automated mixing enhances efficiency and uniformity, enabling scalable production with consistent results essential for meeting commercial demand.

Manual Mixing: Traditional Techniques and Processes

Manual mixing in bakery relies on traditional techniques where bakers use hand tools such as wooden spoons, whisks, or dough hooks to combine ingredients. This process allows for precise control of texture and consistency, essential for artisanal bread and delicate pastries. Skilled bakers can adjust mixing intensity and duration intuitively, ensuring optimal gluten development and ingredient integration.

Automated Mixing: Modern Technology in the Bakery

Automated mixing in bakeries utilizes advanced machinery equipped with programmable settings for consistent dough texture and precise ingredient integration. This technology reduces labor costs and enhances production efficiency by allowing continuous operation and minimizing human error. Modern automated mixers feature sensor-driven systems that adapt mixing speed and duration to specific recipes, ensuring optimal product quality and uniformity.

Comparing Consistency: Manual vs Automated Mixing

Manual mixing in bakery often results in variable dough consistency due to human factors like strength and technique, impacting the final product quality. Automated mixing machines utilize precise, programmable settings to ensure uniform ingredient incorporation and consistent dough texture across batches. Consistent dough quality achieved with automated mixing enhances product reliability, reduces waste, and improves overall production efficiency.

Time Efficiency: Which Method Saves More Hours?

Automated mixing in bakeries significantly reduces mixing time by maintaining consistent speed and precision, saving up to 50% more hours compared to manual mixing. Manual mixing requires intensive labor and frequent breaks, often extending the process and increasing the risk of inconsistent dough texture. Investing in automated mixers enhances overall bakery productivity by enabling faster batch turnover and reducing operator fatigue.

Quality Control: Human Touch or Machine Precision?

Manual mixing in bakery offers precise control over dough texture and consistency through sensory feedback, ensuring artisanal quality and adaptability to ingredient variations. Automated mixing provides consistent speed and thorough ingredient integration, reducing human error and enhancing product uniformity on large scales. Quality control depends on balancing human expertise's tactile judgment with machine precision's reproducibility for optimal bakery outcomes.

Cost Analysis: Manual Labor vs Automation Investment

Manual mixing in bakeries incurs higher ongoing costs due to labor wages, potential for inconsistent product quality, and slower production rates, impacting overall efficiency. Automated mixing requires significant upfront investment in machinery and maintenance but reduces labor costs, increases production speed, and ensures consistent dough quality, leading to long-term savings. Evaluating cost analysis reveals that automation yields better return on investment as batch sizes and production demands increase.

Scaling Production: Limitations and Opportunities

Manual mixing in bakery production often limits scaling due to inconsistent dough texture and slower batch processing times, impacting overall product uniformity and output capacity. Automated mixing systems offer precise ingredient blending, increased mixing speed, and repeatable results, enabling bakeries to scale production efficiently while maintaining quality standards. However, initial investment costs and equipment maintenance present challenges for small-scale operations considering automated solutions.

Safety and Ergonomics: Reducing Workplace Injuries

Manual mixing in bakeries often leads to repetitive strain injuries and wrist fatigue due to prolonged physical effort, increasing the risk of workplace accidents. Automated mixing machines minimize manual labor, offering consistent speed and torque while reducing operator exposure to hazards like heavy lifting and repetitive motions. Prioritizing ergonomic design and safety features in automation enhances worker wellbeing and decreases injury-related downtime in bakery environments.

Choosing the Right Mixing Method for Your Bakery

Selecting the optimal mixing method for your bakery depends on batch size, product consistency, and labor availability. Manual mixing offers precise control ideal for small-scale or artisanal batches, while automated mixers ensure uniformity and efficiency for high-volume production. Evaluating equipment costs, staff expertise, and desired dough texture helps maximize bakery productivity and product quality.

Manual Mixing vs Automated Mixing Infographic

bizdif.com

bizdif.com