Dough lamination involves folding and rolling layers of butter into the dough to create flaky, airy pastries like croissants, while straight dough combines all ingredients in a single mix for a denser, more uniform bread texture. Laminated dough requires longer preparation and precise temperature control to maintain the butter layers, resulting in light, layered baked goods. Straight dough is simpler and faster, ideal for breads such as sandwich loaves where a consistent crumb and quicker production are desired.

Table of Comparison

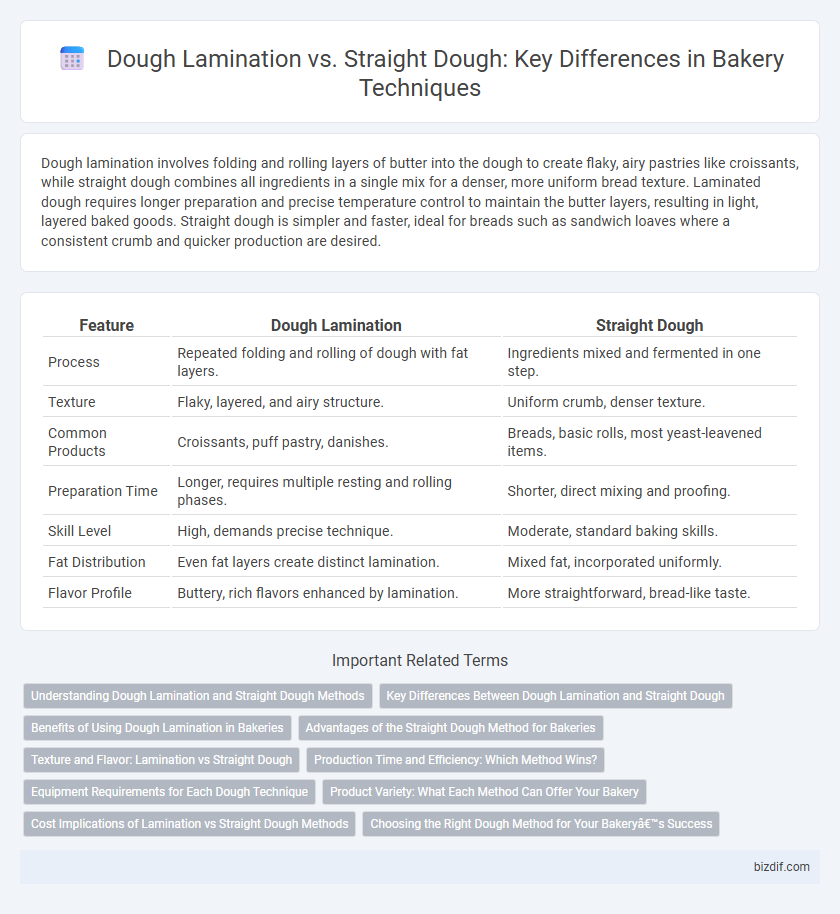

| Feature | Dough Lamination | Straight Dough |

|---|---|---|

| Process | Repeated folding and rolling of dough with fat layers. | Ingredients mixed and fermented in one step. |

| Texture | Flaky, layered, and airy structure. | Uniform crumb, denser texture. |

| Common Products | Croissants, puff pastry, danishes. | Breads, basic rolls, most yeast-leavened items. |

| Preparation Time | Longer, requires multiple resting and rolling phases. | Shorter, direct mixing and proofing. |

| Skill Level | High, demands precise technique. | Moderate, standard baking skills. |

| Fat Distribution | Even fat layers create distinct lamination. | Mixed fat, incorporated uniformly. |

| Flavor Profile | Buttery, rich flavors enhanced by lamination. | More straightforward, bread-like taste. |

Understanding Dough Lamination and Straight Dough Methods

Dough lamination involves folding and rolling layers of butter into the dough, creating a flaky and airy texture ideal for croissants and puff pastries, while straight dough combines all ingredients in a single mix, resulting in a denser, more uniform crumb typical of breads and rolls. Lamination requires precise temperature control and multiple resting periods to achieve distinct layers, whereas straight dough is faster and simpler, suitable for large-scale production with consistent quality. Understanding these methods helps bakers optimize texture, flavor development, and production efficiency based on the desired bakery product.

Key Differences Between Dough Lamination and Straight Dough

Dough lamination involves folding and layering butter into dough multiple times to create flaky, airy textures, commonly used in croissants and puff pastry, whereas straight dough mixes all ingredients at once without layering, producing a denser crumb typical of breads like sandwich loaves. Lamination requires precise temperature control and longer preparation time to maintain butter consistency, contrasting with the quicker, simpler straight dough method that favors efficiency and consistent fermentation. The structural differences in these techniques result in distinct textural outcomes, with lamination emphasizing lightness and flakiness versus the straightforward crumb of straight dough products.

Benefits of Using Dough Lamination in Bakeries

Dough lamination enhances bakery product texture by creating multiple thin layers of dough and fat, resulting in a flaky, buttery crumb ideal for croissants and puff pastries. The process improves oven spring and volume, yielding consistent rise and a delicate crust that delights consumers. Bakers achieve better control over dough extensibility and moisture retention, leading to longer shelf life and superior product quality.

Advantages of the Straight Dough Method for Bakeries

The straight dough method offers significant advantages for bakeries, including a simplified process that reduces production time and labor costs by combining all ingredients in a single mixing phase. This method enhances consistency and scalability, making it easier to achieve uniform dough quality batch after batch. Additionally, straight dough allows for more flexibility in ingredient adjustments, accommodating diverse recipes and bakery needs without compromising texture or flavor.

Texture and Flavor: Lamination vs Straight Dough

Laminated dough creates a flaky, layered texture with rich buttery flavor due to multiple folds incorporating fat, ideal for croissants and Danish pastries. Straight dough produces a denser crumb with a more straightforward, yeasty taste, common in breads like sandwich loaves and buns. The lamination process enhances complexity in texture and flavor, whereas straight dough emphasizes simplicity and softness.

Production Time and Efficiency: Which Method Wins?

Dough lamination, involving multiple folds and layers, typically requires more production time than the straightforward mixing and resting of straight dough, impacting overall bakery efficiency. However, lamination enhances texture and flakiness, justifying the longer process in premium products like croissants and puff pastries. Straight dough methods excel in faster production cycles and higher throughput, making them ideal for large-scale operations focused on efficiency.

Equipment Requirements for Each Dough Technique

Dough lamination requires specialized equipment such as dough sheeters and rollers to create multiple thin layers of dough and fat, essential for producing flaky pastries like croissants and puff pastries. In contrast, the straight dough method depends primarily on mixers and proofing cabinets, focusing on simpler blending and fermentation processes without the need for extensive mechanical layering. The choice of equipment directly influences workflow efficiency and product texture in bakery operations.

Product Variety: What Each Method Can Offer Your Bakery

Dough lamination creates delicate, flaky pastries like croissants and Danish with multiple buttery layers, enhancing product variety with rich textures. Straight dough methods provide versatility for a wide range of breads and rolls, offering fluffier, denser products ideal for everyday baked goods. Combining both techniques expands your bakery's menu, catering to diverse customer preferences from artisanal laminated pastries to hearty, traditional breads.

Cost Implications of Lamination vs Straight Dough Methods

Dough lamination involves folding and layering dough with fat, increasing ingredient costs and labor time compared to the straight dough method, which mixes all ingredients at once. Lamination requires specialized equipment and skilled labor, driving up production expenses, but offers superior texture and flakiness that may justify the higher cost in premium baked goods. Straight dough is more economical for large-scale production due to lower ingredient waste and faster processing, making it ideal for cost-sensitive bakery operations.

Choosing the Right Dough Method for Your Bakery’s Success

Dough lamination creates layers through folding and rolling, ideal for flaky pastries like croissants, while straight dough mixes ingredients directly, producing a denser texture suited for breads. Selecting the right dough method depends on your bakery's product range, desired texture, and production capacity. Optimizing this choice enhances product quality, operational efficiency, and customer satisfaction.

Dough Lamination vs Straight Dough Infographic

bizdif.com

bizdif.com