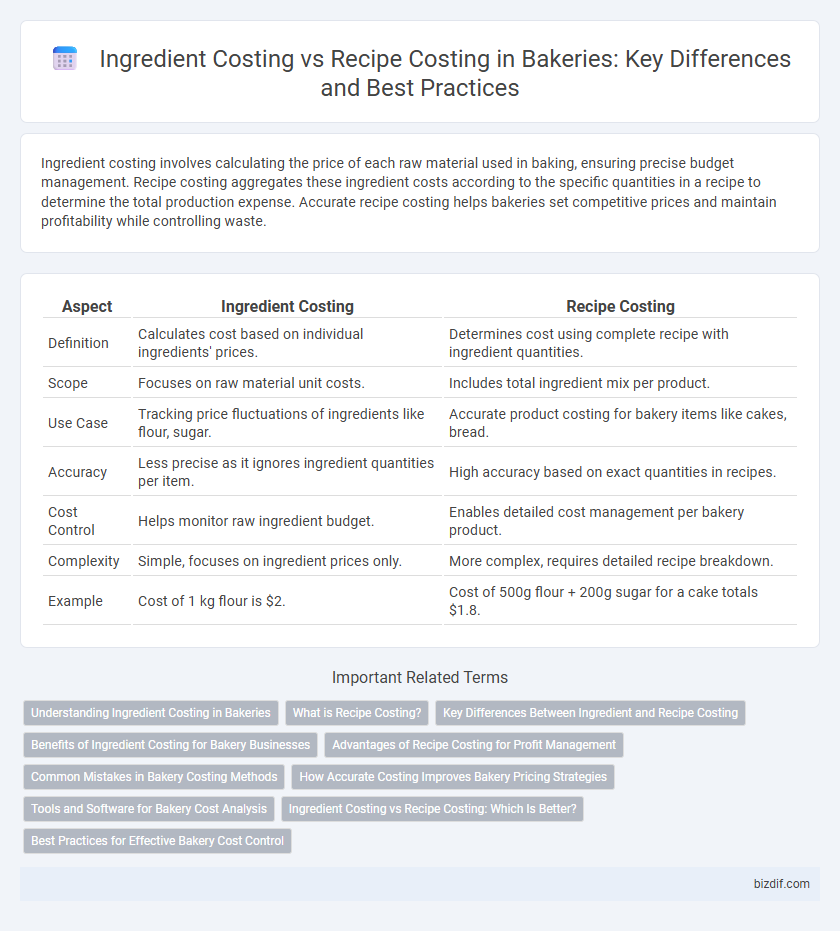

Ingredient costing involves calculating the price of each raw material used in baking, ensuring precise budget management. Recipe costing aggregates these ingredient costs according to the specific quantities in a recipe to determine the total production expense. Accurate recipe costing helps bakeries set competitive prices and maintain profitability while controlling waste.

Table of Comparison

| Aspect | Ingredient Costing | Recipe Costing |

|---|---|---|

| Definition | Calculates cost based on individual ingredients' prices. | Determines cost using complete recipe with ingredient quantities. |

| Scope | Focuses on raw material unit costs. | Includes total ingredient mix per product. |

| Use Case | Tracking price fluctuations of ingredients like flour, sugar. | Accurate product costing for bakery items like cakes, bread. |

| Accuracy | Less precise as it ignores ingredient quantities per item. | High accuracy based on exact quantities in recipes. |

| Cost Control | Helps monitor raw ingredient budget. | Enables detailed cost management per bakery product. |

| Complexity | Simple, focuses on ingredient prices only. | More complex, requires detailed recipe breakdown. |

| Example | Cost of 1 kg flour is $2. | Cost of 500g flour + 200g sugar for a cake totals $1.8. |

Understanding Ingredient Costing in Bakeries

Ingredient costing in bakeries involves calculating the exact expenses of raw materials such as flour, sugar, yeast, and butter used in each product. This precise cost analysis helps bakeries set accurate pricing, manage inventory efficiently, and control profit margins effectively. Tracking ingredient costs is essential for optimizing recipe formulations and minimizing waste in bakery operations.

What is Recipe Costing?

Recipe costing is a detailed method used in bakeries to calculate the total expense of producing a specific baked good by summing the cost of each ingredient in the recipe. This approach ensures precise pricing, helps maintain profit margins, and improves inventory management by tracking ingredient quantities and costs. Accurate recipe costing supports effective menu pricing strategies and reduces waste by aligning production with cost data.

Key Differences Between Ingredient and Recipe Costing

Ingredient costing calculates the price of individual raw materials like flour, sugar, and butter used in a bakery, focusing on unit prices and quantities. Recipe costing aggregates these ingredient costs along with labor, overhead, and wastage to determine the total cost per finished baked product. The key difference lies in ingredient costing serving as a component-level analysis, while recipe costing provides a comprehensive, product-level expense assessment.

Benefits of Ingredient Costing for Bakery Businesses

Ingredient costing enables bakery businesses to precisely track the cost of each raw material, improving overall budget management and reducing waste. It offers granular insight into price fluctuations of key components like flour, sugar, and butter, allowing for more accurate pricing strategies. This method enhances cost control, facilitates inventory management, and supports profitability by identifying the most cost-effective ingredient suppliers.

Advantages of Recipe Costing for Profit Management

Recipe costing provides precise control over ingredient quantities, allowing bakeries to accurately calculate production expenses and optimize profit margins. By linking costs directly to each recipe, bakeries can identify cost-saving opportunities and adjust pricing strategies to maintain competitiveness. This method enhances financial planning and reduces waste, contributing to improved overall profitability in bakery operations.

Common Mistakes in Bakery Costing Methods

Common mistakes in bakery costing methods include failing to account for ingredient wastage and portion sizes accurately, leading to skewed ingredient costing. Another error involves neglecting overhead expenses like labor and utilities in recipe costing, which results in underestimating total production costs. Inconsistent measurement units and ignoring ingredient price fluctuations further distort cost calculations, impacting profitability analysis.

How Accurate Costing Improves Bakery Pricing Strategies

Accurate ingredient costing ensures precise tracking of individual components, enabling bakers to calculate exact expenses per recipe. Recipe costing integrates these ingredient costs with labor and overhead, providing a comprehensive view of total production expenses. This accuracy in costing allows bakeries to set competitive prices that optimize profit margins while maintaining product quality and customer satisfaction.

Tools and Software for Bakery Cost Analysis

Bakery cost analysis relies heavily on specialized tools and software designed for ingredient costing and recipe costing to optimize production expenses and maximize profitability. Software like CostGuard and BakeSmart enable bakers to calculate precise ingredient costs by factoring in purchase prices, wastage, and yield percentages, while also facilitating recipe costing by aggregating ingredient costs to determine item pricing and profit margins. Advanced bakery management platforms integrate inventory tracking, supplier price updates, and batch scaling features to streamline cost control and improve financial accuracy in bakery operations.

Ingredient Costing vs Recipe Costing: Which Is Better?

Ingredient costing offers precise control over individual components, allowing bakers to track fluctuating prices and manage inventory efficiently, while recipe costing provides a comprehensive overview of total production expenses by bundling all ingredients into one cost. Recipe costing simplifies pricing and profit margin calculations, but ingredient costing enables more granular analysis and quicker adjustments based on supplier price changes or ingredient substitutions. Choosing between ingredient costing and recipe costing depends on bakery size, complexity, and the need for detailed cost insights versus streamlined financial management.

Best Practices for Effective Bakery Cost Control

Ingredient costing involves calculating expenses based on individual raw materials, while recipe costing aggregates these costs to reflect the complete product's expense. Accurate measurement, standardized recipes, and regular price updates ensure precise cost tracking, minimizing waste and maximizing profit margins. Implementing software tools for cost analysis and adjusting recipes based on ingredient price fluctuations are key best practices for effective bakery cost control.

Ingredient Costing vs Recipe Costing Infographic

bizdif.com

bizdif.com