Frozen dough offers convenience and extended shelf life, allowing bakeries to prepare batches in advance without compromising texture. Fresh dough provides superior flavor and a more delicate crumb, making it ideal for artisanal breads and pastries. Choosing between frozen and fresh dough depends on the balance between efficiency and quality desired in the bakery's production process.

Table of Comparison

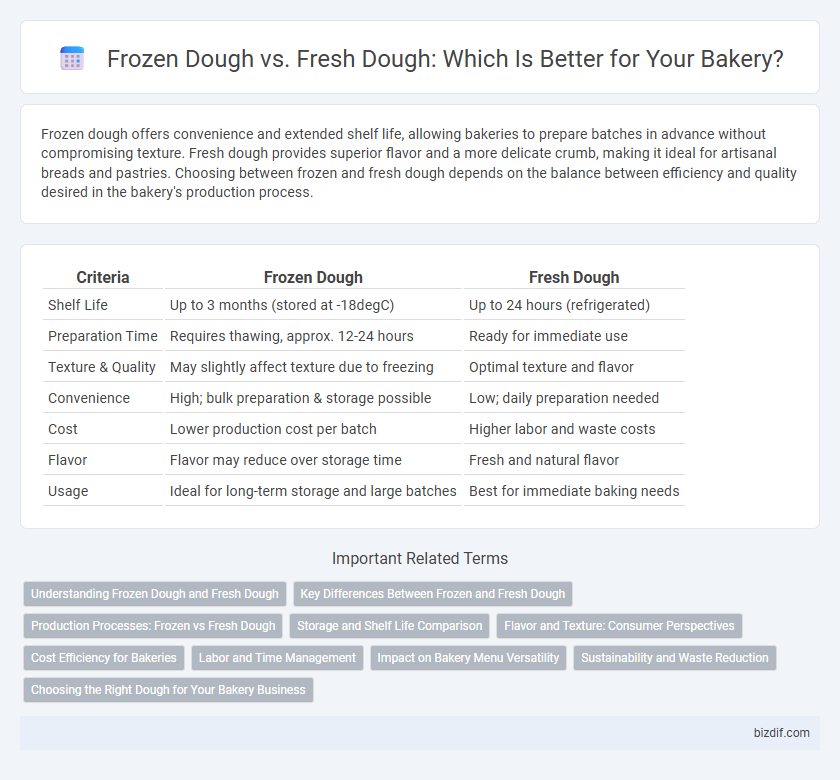

| Criteria | Frozen Dough | Fresh Dough |

|---|---|---|

| Shelf Life | Up to 3 months (stored at -18degC) | Up to 24 hours (refrigerated) |

| Preparation Time | Requires thawing, approx. 12-24 hours | Ready for immediate use |

| Texture & Quality | May slightly affect texture due to freezing | Optimal texture and flavor |

| Convenience | High; bulk preparation & storage possible | Low; daily preparation needed |

| Cost | Lower production cost per batch | Higher labor and waste costs |

| Flavor | Flavor may reduce over storage time | Fresh and natural flavor |

| Usage | Ideal for long-term storage and large batches | Best for immediate baking needs |

Understanding Frozen Dough and Fresh Dough

Frozen dough preserves the yeast activity and gluten structure by halting fermentation at subzero temperatures, allowing bakers to store it for extended periods without compromising dough quality. Fresh dough, freshly mixed and allowed to ferment immediately, offers optimal elasticity and flavor development but requires precise timing for baking. Understanding the biochemical effects of freezing on yeast viability and gluten network guides bakers in choosing between frozen and fresh dough for consistent product quality.

Key Differences Between Frozen and Fresh Dough

Frozen dough retains yeast viability and gluten structure through freezing, allowing for extended shelf life and convenience in batch preparation while possibly affecting texture and rise time once thawed. Fresh dough offers superior flavor complexity and optimal fermentation since it undergoes immediate proofing without the stress of low-temperature storage. Bakers must balance frozen dough's storage benefits against fresh dough's enhanced taste and texture to meet production demands and product quality standards.

Production Processes: Frozen vs Fresh Dough

Frozen dough streamlines production processes by allowing bulk preparation, extended storage, and on-demand thawing, minimizing waste and labor costs. Fresh dough requires immediate use, necessitating precise scheduling and faster turnover in bakery operations to maintain optimal quality. Industry data reveals that frozen dough can sustain dough viability for up to 90 days, while fresh dough typically remains optimal only for 24-48 hours post-preparation.

Storage and Shelf Life Comparison

Frozen dough can be stored for several weeks to months at temperatures below 0degF (-18degC), maintaining its yeast activity and dough quality, whereas fresh dough typically lasts only 1 to 2 days under refrigeration at 40degF (4degC). The extended shelf life of frozen dough reduces waste and enables bulk production, while fresh dough offers quicker preparation but requires immediate use or short-term storage. Proper thawing of frozen dough is essential to preserve texture and rise, ensuring consistent bakery product quality.

Flavor and Texture: Consumer Perspectives

Frozen dough often retains a slightly less robust flavor compared to fresh dough due to the freezing process, which can affect yeast activity and gluten development. Consumers typically notice that fresh dough provides a softer, more elastic texture with a richer, more complex taste profile. While frozen dough offers convenience and longer shelf life, many consumers prefer fresh dough for its superior flavor depth and tender crumb.

Cost Efficiency for Bakeries

Frozen dough reduces waste and extends shelf life, significantly lowering operational costs for bakeries by minimizing daily production inconsistencies. Fresh dough requires immediate use, increasing labor expenses and the risk of overproduction or spoilage. Investing in frozen dough enhances inventory management and ensures consistent product quality, optimizing overall cost efficiency.

Labor and Time Management

Frozen dough significantly reduces labor costs by minimizing the need for daily mixing and fermentation, allowing bakers to prepare large batches in advance. This time management advantage enables consistent production schedules and faster turnaround, improving overall bakery efficiency. In contrast, fresh dough requires continuous attention and skilled labor to manage timing and quality, which can increase operational complexity and labor expenses.

Impact on Bakery Menu Versatility

Frozen dough offers bakeries extended menu versatility by enabling the preparation of a wide variety of products without daily dough preparation, ensuring consistent quality and reducing labor costs. Fresh dough provides superior flavor and texture, essential for artisanal and specialty items that require unique characteristics and immediate baking. Combining frozen and fresh dough options allows bakeries to expand their offerings while maintaining efficiency and product authenticity.

Sustainability and Waste Reduction

Frozen dough significantly enhances sustainability by extending shelf life, reducing food waste compared to fresh dough that spoils faster. Utilizing frozen dough allows bakeries to produce on-demand, minimizing excess production and lowering energy consumption associated with frequent baking cycles. The reduction in discarded dough and fewer transportation runs further contribute to eco-friendly bakery operations.

Choosing the Right Dough for Your Bakery Business

Selecting between frozen dough and fresh dough depends on your bakery's production capacity, desired shelf life, and product consistency. Frozen dough offers extended storage, reduced waste, and convenient portion control, ideal for high-volume or seasonal demands. Fresh dough delivers superior flavor and texture, appealing to artisanal bakeries prioritizing quality and immediate consumption.

Frozen dough vs Fresh dough Infographic

bizdif.com

bizdif.com