Gluten-free bakery production requires dedicated equipment and rigorous cross-contamination controls to ensure product safety for individuals with gluten intolerance or celiac disease. Unlike conventional bakery production, which often uses shared facilities and ingredients containing gluten, gluten-free production demands specific sourcing of alternative flours such as rice, almond, or tapioca to maintain texture and flavor. This specialized approach enhances allergen management but may increase costs and impact scalability compared to traditional methods.

Table of Comparison

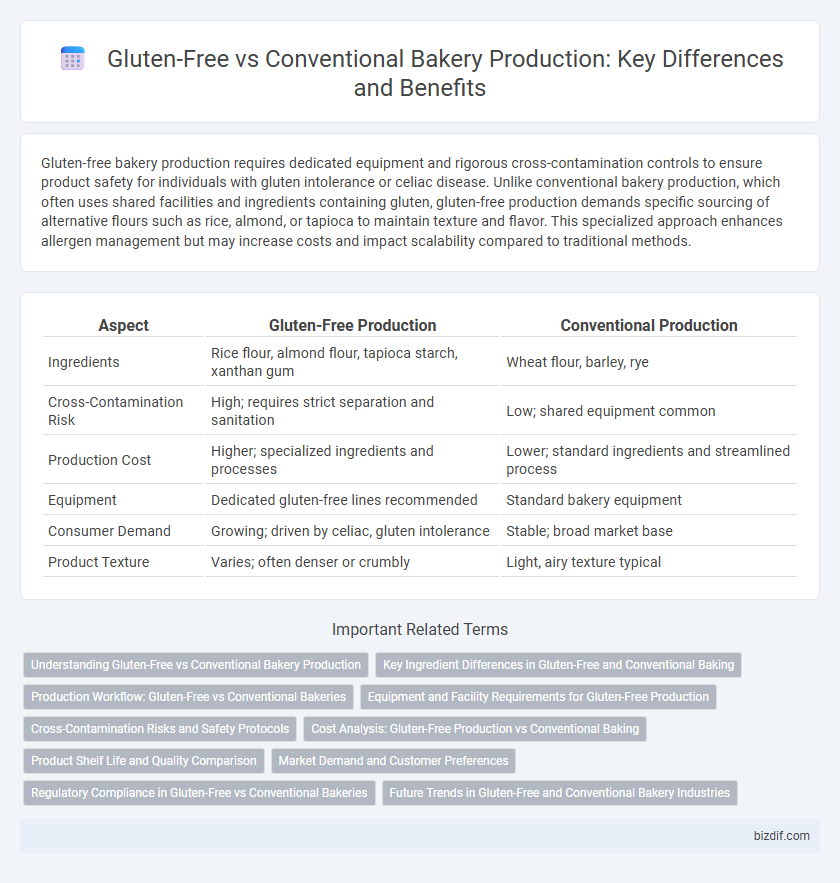

| Aspect | Gluten-Free Production | Conventional Production |

|---|---|---|

| Ingredients | Rice flour, almond flour, tapioca starch, xanthan gum | Wheat flour, barley, rye |

| Cross-Contamination Risk | High; requires strict separation and sanitation | Low; shared equipment common |

| Production Cost | Higher; specialized ingredients and processes | Lower; standard ingredients and streamlined process |

| Equipment | Dedicated gluten-free lines recommended | Standard bakery equipment |

| Consumer Demand | Growing; driven by celiac, gluten intolerance | Stable; broad market base |

| Product Texture | Varies; often denser or crumbly | Light, airy texture typical |

Understanding Gluten-Free vs Conventional Bakery Production

Gluten-free bakery production requires specialized ingredients such as rice flour, almond flour, or tapioca starch to replace wheat-based products used in conventional baking, which rely on gluten for dough elasticity and structure. This difference demands distinct manufacturing processes to prevent cross-contamination and maintain product integrity, often involving dedicated equipment and strict allergen controls. Understanding these variations is essential for maintaining quality and meeting the dietary needs of gluten-intolerant consumers in gluten-free bakery operations.

Key Ingredient Differences in Gluten-Free and Conventional Baking

Gluten-free baking relies on alternative flours such as almond, rice, or tapioca to replace wheat flour, which contains gluten, the primary protein providing elasticity and structure in conventional baking. Key ingredients like xanthan gum or guar gum are often added in gluten-free recipes to mimic gluten's binding properties, ensuring proper texture and moisture retention. Conventional baking primarily uses wheat-based flours rich in gluten, enabling dough development and a characteristic airy crumb without needing additional stabilizers.

Production Workflow: Gluten-Free vs Conventional Bakeries

Gluten-free production workflows require stringent contamination controls, including separate equipment and dedicated production areas to prevent gluten cross-contact, which increases complexity compared to conventional bakery operations. Ingredient sourcing is more meticulous in gluten-free bakeries, focusing on certified gluten-free grains and alternative flours that often require different mixing and baking times. While conventional bakeries benefit from a streamlined process with standard wheat-based recipes, gluten-free facilities implement rigorous testing and cleaning protocols to maintain product safety and compliance with gluten-free labeling standards.

Equipment and Facility Requirements for Gluten-Free Production

Gluten-free production requires dedicated equipment and facilities to prevent cross-contamination with gluten-containing ingredients, often involving separate mixers, ovens, and storage areas. Strict cleaning protocols and air filtration systems are essential to maintain a gluten-free environment, ensuring compliance with safety standards and allergen controls. Conventional production typically allows shared equipment but cannot guarantee gluten-free safety without rigorous cleaning and testing processes.

Cross-Contamination Risks and Safety Protocols

Gluten-free bakery production demands strict separation from conventional lines to prevent cross-contamination risks that can trigger severe allergic reactions or celiac disease symptoms. Dedicated equipment, thorough cleaning protocols, and staff training are essential safety measures to maintain gluten-free integrity throughout production. Even trace amounts of gluten can compromise product safety, making rigorous control practices a critical aspect of gluten-free bakery operations.

Cost Analysis: Gluten-Free Production vs Conventional Baking

Gluten-free production incurs higher costs primarily due to expensive specialty ingredients like xanthan gum, rice flour, and almond flour, as well as the need for dedicated facilities to prevent cross-contamination. Conventional baking benefits from established supply chains and bulk purchasing of standard wheat-based ingredients, significantly reducing ingredient and operational expenses. These cost disparities often result in gluten-free products being priced 20-50% higher than their conventional counterparts.

Product Shelf Life and Quality Comparison

Gluten-free bakery products typically have a shorter shelf life compared to conventional products due to the absence of gluten, which helps retain moisture and structure. The texture and freshness of gluten-free items often decline faster, leading to increased brittleness or dryness over time. Conventional baked goods benefit from gluten's elasticity, resulting in longer-lasting softness, improved volume, and consistent quality throughout their shelf life.

Market Demand and Customer Preferences

Gluten-free bakery products have seen a significant surge in market demand, driven by increasing awareness of celiac disease and gluten sensitivities. Consumers prioritize clean-label ingredients, natural flavors, and allergen-free certifications when choosing gluten-free options over conventional baked goods. This shift in customer preferences is prompting bakeries to expand gluten-free lines while maintaining quality and taste comparable to traditional products.

Regulatory Compliance in Gluten-Free vs Conventional Bakeries

Gluten-free production requires strict adherence to regulations such as the FDA's gluten-free labeling rule, which mandates products contain less than 20 parts per million (ppm) of gluten. Conventional bakeries face broader food safety standards but do not have to meet the specific gluten threshold, making cross-contamination controls less stringent. Compliance in gluten-free bakeries involves detailed allergen management systems and frequent testing to ensure product safety and regulatory conformity.

Future Trends in Gluten-Free and Conventional Bakery Industries

Future trends in the bakery industry highlight a growing demand for gluten-free products driven by increasing celiac disease awareness and consumer preference for healthier options, pushing manufacturers to innovate with alternative flours like almond, coconut, and chickpea. Conventional bakery production continues to evolve through automation, sustainable sourcing, and enhanced shelf-life technologies to meet mass-market needs while balancing cost efficiency. The integration of clean-label ingredients and functional additives characterizes the convergence of gluten-free and conventional bakery sectors, aligning with consumer demands for transparency and nutritional benefits.

Gluten-free production vs Conventional production Infographic

bizdif.com

bizdif.com