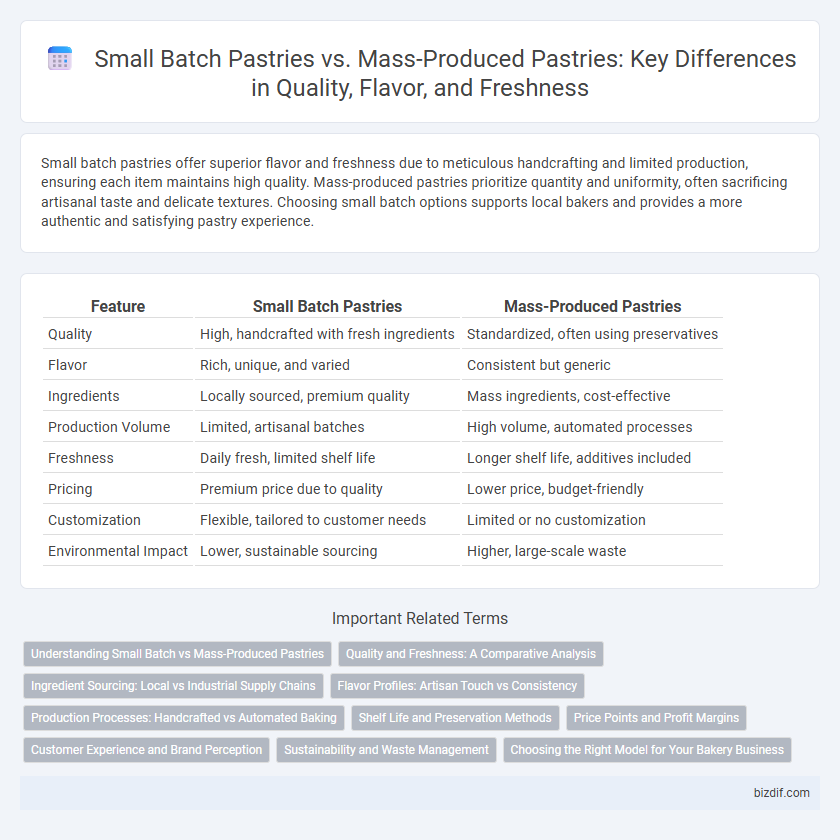

Small batch pastries offer superior flavor and freshness due to meticulous handcrafting and limited production, ensuring each item maintains high quality. Mass-produced pastries prioritize quantity and uniformity, often sacrificing artisanal taste and delicate textures. Choosing small batch options supports local bakers and provides a more authentic and satisfying pastry experience.

Table of Comparison

| Feature | Small Batch Pastries | Mass-Produced Pastries |

|---|---|---|

| Quality | High, handcrafted with fresh ingredients | Standardized, often using preservatives |

| Flavor | Rich, unique, and varied | Consistent but generic |

| Ingredients | Locally sourced, premium quality | Mass ingredients, cost-effective |

| Production Volume | Limited, artisanal batches | High volume, automated processes |

| Freshness | Daily fresh, limited shelf life | Longer shelf life, additives included |

| Pricing | Premium price due to quality | Lower price, budget-friendly |

| Customization | Flexible, tailored to customer needs | Limited or no customization |

| Environmental Impact | Lower, sustainable sourcing | Higher, large-scale waste |

Understanding Small Batch vs Mass-Produced Pastries

Small batch pastries emphasize quality and artisanal techniques, often handcrafted to ensure freshness and unique flavors, while mass-produced pastries prioritize volume and consistency using automated processes. The small batch approach allows for customization and minimal preservatives, appealing to consumers seeking authenticity and gourmet experiences. In contrast, mass-produced pastries target broad markets, offering affordability and longer shelf life but often sacrificing texture and flavor complexity.

Quality and Freshness: A Comparative Analysis

Small batch pastries are crafted with meticulous attention to ingredient quality and preparation techniques, resulting in superior freshness and flavor retention compared to mass-produced pastries, which often rely on preservatives and extended shelf life. The artisanal process in small batches ensures each pastry is baked at peak freshness, enhancing texture and taste, whereas mass production prioritizes quantity, frequently compromising on ingredient customization and freshness. This comparative analysis highlights that small batch pastries offer a distinctly higher standard of quality and freshness, appealing to consumers seeking premium bakery products.

Ingredient Sourcing: Local vs Industrial Supply Chains

Small batch pastries often rely on locally sourced, high-quality ingredients from regional farms and artisanal producers, ensuring fresher flavors and supporting sustainable agriculture. Mass-produced pastries typically use ingredients supplied through extensive industrial supply chains, which prioritize cost-efficiency and consistency over ingredient origin. This difference in ingredient sourcing directly impacts the taste, nutritional value, and environmental footprint of the finished baked goods.

Flavor Profiles: Artisan Touch vs Consistency

Small batch pastries showcase complex flavor profiles, handcrafted with artisan techniques that highlight fresh, high-quality ingredients and nuanced textures. Mass-produced pastries prioritize uniformity and consistent taste, often relying on standardized recipes and preservatives to maintain shelf life. The contrast between the two lies in the rich, layered flavors of small batches versus the predictable, homogenized taste of large-scale production.

Production Processes: Handcrafted vs Automated Baking

Small batch pastries are meticulously handcrafted, allowing bakers to control every detail of the production process, resulting in unique flavors and textures. Mass-produced pastries rely on automated baking systems that prioritize speed and uniformity, often sacrificing artisanal quality for higher output. The contrast between manual techniques and mechanized production directly impacts the freshness, taste, and overall experience of the pastries.

Shelf Life and Preservation Methods

Small batch pastries typically feature fresher ingredients and lack preservatives, resulting in a shorter shelf life of 1-3 days, which necessitates immediate consumption or refrigeration to maintain quality. Mass-produced pastries often contain stabilizers and preservatives such as sorbic acid or calcium propionate, extending their shelf life to several weeks under controlled packaging conditions. Modified atmosphere packaging (MAP) and vacuum sealing are common preservation methods used in mass production to inhibit microbial growth and prolong freshness.

Price Points and Profit Margins

Small batch pastries typically command higher price points due to the artisanal techniques and premium ingredients involved, resulting in enhanced profit margins despite lower production volumes. Mass-produced pastries benefit from economies of scale, enabling lower cost per unit and competitive pricing, but often yield slimmer profit margins because of standardized recipes and bulk ingredients. Balancing production methods with market demand allows bakeries to optimize profitability across diverse consumer segments.

Customer Experience and Brand Perception

Small batch pastries offer a handcrafted quality that enhances customer experience through unique flavors and fresher ingredients, fostering a strong emotional connection to the brand. Mass-produced pastries provide consistency and affordability but often sacrifice artisanal appeal, which can lead to a perception of lower quality and reduced brand loyalty. Consumers increasingly value authenticity and craftsmanship, making small batch pastries a strategic advantage for premium bakery brands.

Sustainability and Waste Management

Small batch pastries prioritize sustainability by using locally sourced ingredients and producing limited quantities, which significantly reduces food waste and energy consumption. Mass-produced pastries often generate excess inventory, leading to higher levels of unsold products discarded, contributing to landfill waste. Employing small batch methods improves waste management outcomes by aligning production closely with actual consumer demand and minimizing packaging waste.

Choosing the Right Model for Your Bakery Business

Small batch pastries emphasize artisanal quality, freshness, and unique flavors, making them ideal for bakeries aiming to attract discerning customers and build brand loyalty. Mass-produced pastries focus on efficiency, consistency, and scalability, suited for high-volume sales in retail chains or supermarkets. Selecting the right model depends on your target market, production capacity, and desired product differentiation to maximize profitability and customer satisfaction.

Small batch pastries vs Mass-produced pastries Infographic

bizdif.com

bizdif.com