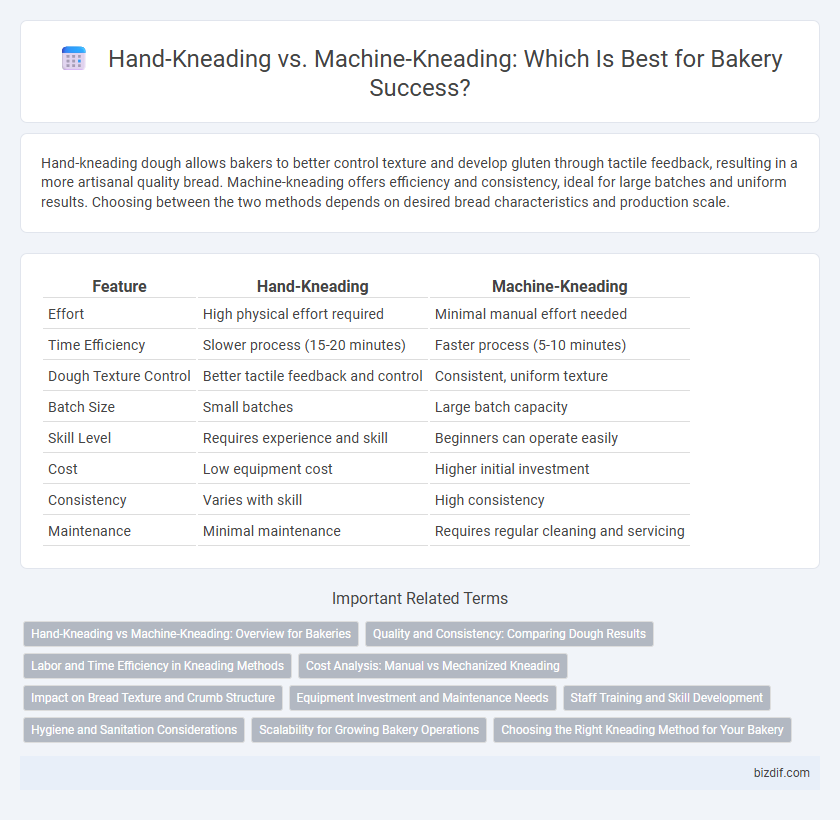

Hand-kneading dough allows bakers to better control texture and develop gluten through tactile feedback, resulting in a more artisanal quality bread. Machine-kneading offers efficiency and consistency, ideal for large batches and uniform results. Choosing between the two methods depends on desired bread characteristics and production scale.

Table of Comparison

| Feature | Hand-Kneading | Machine-Kneading |

|---|---|---|

| Effort | High physical effort required | Minimal manual effort needed |

| Time Efficiency | Slower process (15-20 minutes) | Faster process (5-10 minutes) |

| Dough Texture Control | Better tactile feedback and control | Consistent, uniform texture |

| Batch Size | Small batches | Large batch capacity |

| Skill Level | Requires experience and skill | Beginners can operate easily |

| Cost | Low equipment cost | Higher initial investment |

| Consistency | Varies with skill | High consistency |

| Maintenance | Minimal maintenance | Requires regular cleaning and servicing |

Hand-Kneading vs Machine-Kneading: Overview for Bakeries

Hand-kneading allows bakers to better control dough texture and develop gluten through tactile feedback, essential for artisan bread varieties. Machine-kneading, ideal for high-volume bakeries, offers consistent kneading speed and reduces labor time, improving efficiency in production. Both methods impact dough quality, with hand-kneading emphasizing craftsmanship and machine-kneading prioritizing scalability.

Quality and Consistency: Comparing Dough Results

Hand-kneading develops gluten more gradually, resulting in bread with a chewier texture and artisanal quality valued by traditional bakers. Machine-kneading ensures consistent dough elasticity and uniform mixing, producing reliable results ideal for commercial bakeries requiring standardized product quality. Dough kneaded by machines often rises more evenly, enhancing overall consistency compared to the variability found in hand-kneaded batches.

Labor and Time Efficiency in Kneading Methods

Hand-kneading requires considerable physical labor and can take 15 to 20 minutes to develop gluten properly, making it less efficient for large batches. Machine-kneading significantly reduces labor intensity and shortens kneading time to as little as 5 to 7 minutes, optimizing bakery workflow. Efficient machine-kneading ensures consistent dough texture while saving labor costs and increasing production capacity.

Cost Analysis: Manual vs Mechanized Kneading

Hand-kneading in bakery processes demands significant labor hours, increasing overall production costs due to slower throughput and higher manual wage expenses. Machine-kneading reduces labor requirements and boosts efficiency, lowering operational costs while maintaining consistent dough quality. Although initial investment in mechanized equipment is higher, the long-term savings in time, labor, and increased output often result in better cost-effectiveness compared to traditional hand-kneading methods.

Impact on Bread Texture and Crumb Structure

Hand-kneading develops gluten more gradually, resulting in a denser bread texture with a chewier crumb structure, offering more artisanal appeal. Machine-kneading, with its consistent and rapid motion, creates a well-oxygenated dough that often produces lighter, fluffier bread with an even crumb. The choice between hand and machine kneading significantly influences the elasticity and air retention in the dough, directly impacting the bread's final texture and volume.

Equipment Investment and Maintenance Needs

Hand-kneading requires minimal equipment investment, relying mainly on basic tools like a mixing bowl and hands, which reduces upfront costs. Machine-kneading demands significant investment in kneading machines that vary in size and capacity, impacting both initial expenditure and ongoing maintenance requirements. Maintenance for machines includes regular cleaning, lubrication, and occasional part replacements, whereas hand-kneading has negligible maintenance needs but higher labor intensity.

Staff Training and Skill Development

Hand-kneading develops artisanal skills, enhancing staff's tactile sense and dough consistency awareness through hands-on practice. Machine-kneading accelerates production while requiring training in equipment operation and maintenance to ensure dough quality and prevent mechanical issues. Combining both methods in staff training programs improves versatility and efficiency in bakery operations.

Hygiene and Sanitation Considerations

Hand-kneading in bakery ensures minimal machinery contact, reducing potential contamination points and allowing bakers to maintain direct control over hygiene. Machine-kneading requires rigorous cleaning protocols to prevent buildup of dough residues and bacterial growth in hard-to-reach parts like mixers and blades. Proper sanitation of equipment combined with hand hygiene practices in manual kneading significantly impacts the overall food safety standards in bakery operations.

Scalability for Growing Bakery Operations

Hand-kneading offers artisanal control but limits scalability in growing bakery operations due to its labor-intensive and time-consuming nature. Machine-kneading accelerates dough preparation, ensuring consistent quality and supporting higher production volumes essential for expanding bakeries. Investing in industrial mixers optimizes workflow efficiency, reduces manual labor costs, and enables meeting increasing customer demand without compromising product quality.

Choosing the Right Kneading Method for Your Bakery

Hand-kneading offers artisanal control and a tactile connection to dough, ideal for small batches and specialized breads where texture and character matter. Machine-kneading ensures consistency and efficiency, perfect for high-volume bakeries aiming to optimize production speed while maintaining dough quality. Selecting the right kneading method depends on your bakery's scale, desired product texture, and workflow priorities.

Hand-kneading vs Machine-kneading Infographic

bizdif.com

bizdif.com