Hand-kneading dough allows bakers to better control texture and develop gluten naturally, resulting in a chewier, artisan-quality bread. Machine-mixing offers consistency and efficiency, making it ideal for large batches and uniform dough production. Choosing between the two methods depends on the desired bread quality, production scale, and time constraints.

Table of Comparison

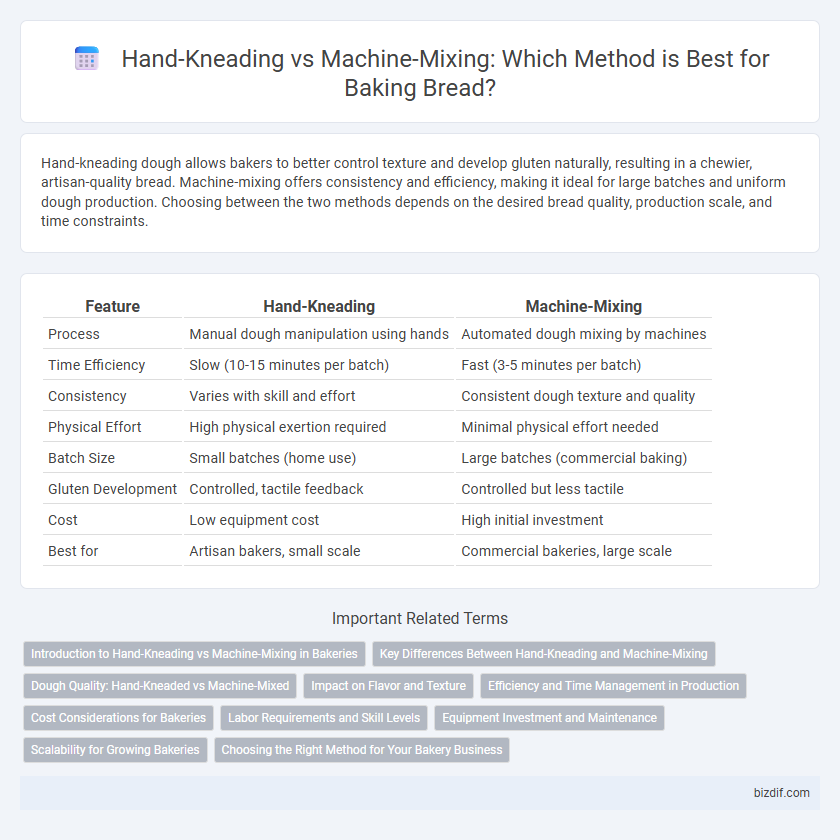

| Feature | Hand-Kneading | Machine-Mixing |

|---|---|---|

| Process | Manual dough manipulation using hands | Automated dough mixing by machines |

| Time Efficiency | Slow (10-15 minutes per batch) | Fast (3-5 minutes per batch) |

| Consistency | Varies with skill and effort | Consistent dough texture and quality |

| Physical Effort | High physical exertion required | Minimal physical effort needed |

| Batch Size | Small batches (home use) | Large batches (commercial baking) |

| Gluten Development | Controlled, tactile feedback | Controlled but less tactile |

| Cost | Low equipment cost | High initial investment |

| Best for | Artisan bakers, small scale | Commercial bakeries, large scale |

Introduction to Hand-Kneading vs Machine-Mixing in Bakeries

Hand-kneading in bakeries involves manually working dough to develop gluten structure, offering bakers precise control over texture and aroma. Machine-mixing accelerates dough production with consistent results, optimizing labor efficiency for large batches. Both methods impact dough hydration and gluten formation, influencing final bread quality and crumb characteristics.

Key Differences Between Hand-Kneading and Machine-Mixing

Hand-kneading dough offers precise tactile control, allowing bakers to gauge dough elasticity and hydration levels, which enhances texture and flavor. Machine-mixing provides consistent, time-efficient mixing with powerful, even kneading, ideal for large batches and uniform crumb development. The primary differences lie in the manual skill and sensory feedback of hand-kneading versus the speed, consistency, and scalability of machine-mixing in bakery production.

Dough Quality: Hand-Kneaded vs Machine-Mixed

Hand-kneaded dough tends to develop a more consistent gluten structure due to the tactile feedback and gradual control during mixing, resulting in a softer, chewier texture. Machine-mixed dough, while faster and more uniform, can sometimes overwork the gluten, leading to a denser crumb and less nuanced flavor profile. Artisan bakers often prefer hand-kneading for its ability to produce superior dough quality and enhanced fermentation outcomes.

Impact on Flavor and Texture

Hand-kneading dough promotes better gluten development, resulting in a chewier texture and more complex flavor due to the incorporation of air and even ingredient mixing. Machine-mixing, however, can achieve consistent dough texture quickly but may sometimes lead to overoxidation, reducing flavor depth and resulting in a less nuanced crumb. Artisanal bakers often prefer hand-kneading for enhanced aromatic profiles and ideal crumb structure in breads like sourdough and artisanal loaves.

Efficiency and Time Management in Production

Hand-kneading dough offers precise texture control but requires significant time and labor, impacting large-scale production efficiency. Machine-mixing accelerates the process, ensuring consistent dough development and reducing overall labor costs in commercial bakeries. Efficient time management is achieved through mechanization, enabling higher batch turnover and optimized resource allocation.

Cost Considerations for Bakeries

Hand-kneading requires minimal equipment investment but increases labor costs due to longer preparation times, impacting overall bakery profitability. Machine-mixing involves upfront expenses for purchasing and maintaining mixers, yet reduces labor hours and improves consistency, leading to long-term cost savings. Selecting between hand-kneading and machine-mixing depends on balancing initial capital outlay against recurring labor expenses and desired production scale.

Labor Requirements and Skill Levels

Hand-kneading dough demands significant physical effort and a high level of skill to achieve the correct texture, making it labor-intensive and suitable for artisanal bakeries. Machine-mixing reduces manual labor drastically, enabling consistent dough quality with less skilled operators, thereby increasing efficiency and throughput in commercial bakeries. The choice between hand-kneading and machine-mixing impacts workforce training, labor costs, and production capacity within bakery operations.

Equipment Investment and Maintenance

Hand-kneading requires minimal initial equipment investment, typically just basic tools like mixing bowls and a sturdy surface, making it cost-effective for small-scale bakeries. Machine-mixing involves higher upfront costs for purchasing industrial mixers but offers efficiency and consistency in dough preparation, which can boost large-scale production. Maintenance for hand-kneading is negligible, while machine mixers demand regular servicing and occasional part replacements to ensure optimal performance and longevity.

Scalability for Growing Bakeries

Hand-kneading limits scalability for growing bakeries due to its time-consuming and labor-intensive nature, making it challenging to meet higher production demands efficiently. Machine-mixing significantly increases capacity by enabling consistent dough preparation at a faster pace, reducing manual labor and allowing bakeries to scale operations smoothly. Optimizing production with industrial mixers streamlines workflow and supports expansion without compromising dough quality or consistency.

Choosing the Right Method for Your Bakery Business

Hand-kneading offers precise control over dough texture and is ideal for artisanal bakeries prioritizing craftsmanship and small batch quality. Machine-mixing improves consistency and efficiency, making it suitable for high-volume bakeries seeking to scale production and reduce labor costs. Evaluating factors such as dough type, batch size, and desired product characteristics is essential when choosing the right kneading method for your bakery business.

Hand-kneading vs Machine-mixing Infographic

bizdif.com

bizdif.com