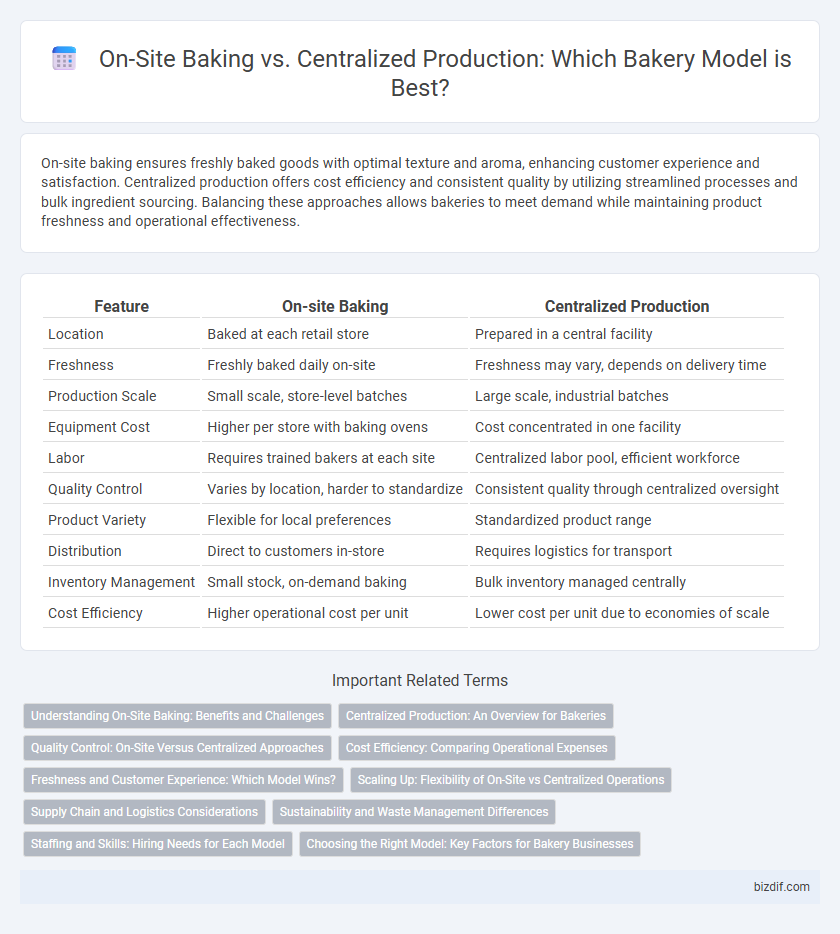

On-site baking ensures freshly baked goods with optimal texture and aroma, enhancing customer experience and satisfaction. Centralized production offers cost efficiency and consistent quality by utilizing streamlined processes and bulk ingredient sourcing. Balancing these approaches allows bakeries to meet demand while maintaining product freshness and operational effectiveness.

Table of Comparison

| Feature | On-site Baking | Centralized Production |

|---|---|---|

| Location | Baked at each retail store | Prepared in a central facility |

| Freshness | Freshly baked daily on-site | Freshness may vary, depends on delivery time |

| Production Scale | Small scale, store-level batches | Large scale, industrial batches |

| Equipment Cost | Higher per store with baking ovens | Cost concentrated in one facility |

| Labor | Requires trained bakers at each site | Centralized labor pool, efficient workforce |

| Quality Control | Varies by location, harder to standardize | Consistent quality through centralized oversight |

| Product Variety | Flexible for local preferences | Standardized product range |

| Distribution | Direct to customers in-store | Requires logistics for transport |

| Inventory Management | Small stock, on-demand baking | Bulk inventory managed centrally |

| Cost Efficiency | Higher operational cost per unit | Lower cost per unit due to economies of scale |

Understanding On-Site Baking: Benefits and Challenges

On-site baking enables bakeries to produce fresh bread and pastries directly where they are sold, ensuring optimal product freshness and enhancing customer experience. This approach reduces transportation costs and delivery times but requires significant investment in skilled staff and baking equipment at each location. Managing consistency and quality across multiple sites presents operational challenges that demand effective training and stringent quality control measures.

Centralized Production: An Overview for Bakeries

Centralized production in bakeries streamlines ingredient sourcing, enhances quality control, and reduces operational costs by consolidating baking processes into a single facility. This approach enables large-scale output with consistent product quality, benefiting from specialized equipment and skilled staff focused on efficiency. Centralized bakeries can better manage inventory, optimize supply chains, and meet high-volume demand without compromising freshness and taste.

Quality Control: On-Site Versus Centralized Approaches

On-site baking allows for immediate quality control with fresh product adjustments and real-time monitoring, ensuring consistent texture and flavor tailored to customer preferences. Centralized production offers standardized quality through advanced equipment and uniform processes, enabling tighter control over ingredient sourcing and batch consistency. Both approaches impact shelf life, product freshness, and customer satisfaction differently, depending on operational scale and quality priorities.

Cost Efficiency: Comparing Operational Expenses

On-site baking incurs higher operational expenses due to labor costs, equipment maintenance, and energy consumption spread across multiple locations. Centralized production reduces costs through economies of scale, streamlined labor management, and bulk purchasing of raw materials. Consolidating baking processes into a single facility enhances cost efficiency by minimizing overhead and optimizing resource allocation.

Freshness and Customer Experience: Which Model Wins?

On-site baking ensures peak freshness by producing goods directly in front of customers, enhancing aroma and visual appeal that significantly boosts customer experience and satisfaction. Centralized production offers consistency and scale but often sacrifices freshness due to transportation and storage times. For bakeries prioritizing aroma, texture, and immediate consumption, on-site baking delivers superior quality and customer engagement.

Scaling Up: Flexibility of On-Site vs Centralized Operations

On-site baking offers greater flexibility for scaling up production by allowing immediate adjustments to product variety and volume based on customer demand, enhancing freshness and customization. Centralized production enables large-scale output with consistent quality control and cost efficiency through streamlined processes and bulk ingredient sourcing. Balancing on-site adaptability and centralized efficiency is key for bakeries aiming to expand while maintaining product quality and responsiveness.

Supply Chain and Logistics Considerations

On-site baking reduces transportation costs and delivery times by producing fresh goods directly at the point of sale, enhancing product quality and customer satisfaction. Centralized production streamlines inventory management, lowers operational costs through economies of scale, and enables bulk purchasing of raw materials, but relies heavily on efficient logistics networks to ensure timely distribution. Balancing supply chain flexibility with centralized efficiency requires robust cold chain management and real-time demand forecasting to minimize spoilage and stockouts.

Sustainability and Waste Management Differences

On-site baking reduces transportation emissions by producing fresh products directly at the retail location, minimizing carbon footprint and packaging waste. Centralized production often benefits from economies of scale in waste management and energy efficiency, enabling better control over ingredient sourcing and bulk waste recycling. However, it may generate higher food waste due to distribution delays and overproduction, impacting overall sustainability efforts.

Staffing and Skills: Hiring Needs for Each Model

On-site baking requires a diverse team with strong artisan skills to handle multiple tasks such as mixing, shaping, and baking throughout the day, demanding continuous staffing and flexible scheduling. Centralized production prioritizes hiring specialized staff focused on batch processing and efficiency, often relying on automation to reduce labor intensity. The distinct skill sets and staffing models impact recruitment strategies, with on-site bakeries seeking versatile bakers and centralized facilities emphasizing technical expertise in large-scale production.

Choosing the Right Model: Key Factors for Bakery Businesses

On-site baking offers freshness and immediate product availability, enhancing customer experience and allowing customization for local demand. Centralized production improves efficiency, reduces labor costs, and ensures consistent quality across multiple locations through standardized processes. Key factors for bakery businesses when choosing between these models include volume of production, distribution logistics, target market preferences, and cost management.

On-site baking vs Centralized production Infographic

bizdif.com

bizdif.com