Hand-laminated dough offers superior flakiness and distinct layers due to the careful folding and resting process carried out by skilled bakers, resulting in a delicate texture and enhanced flavor. Machine-laminated dough provides consistency and speed, ideal for large-scale production, but may compromise the artisan quality and subtle nuances in texture. Choosing between hand and machine lamination depends on whether the priority is traditional craftsmanship or efficient mass production.

Table of Comparison

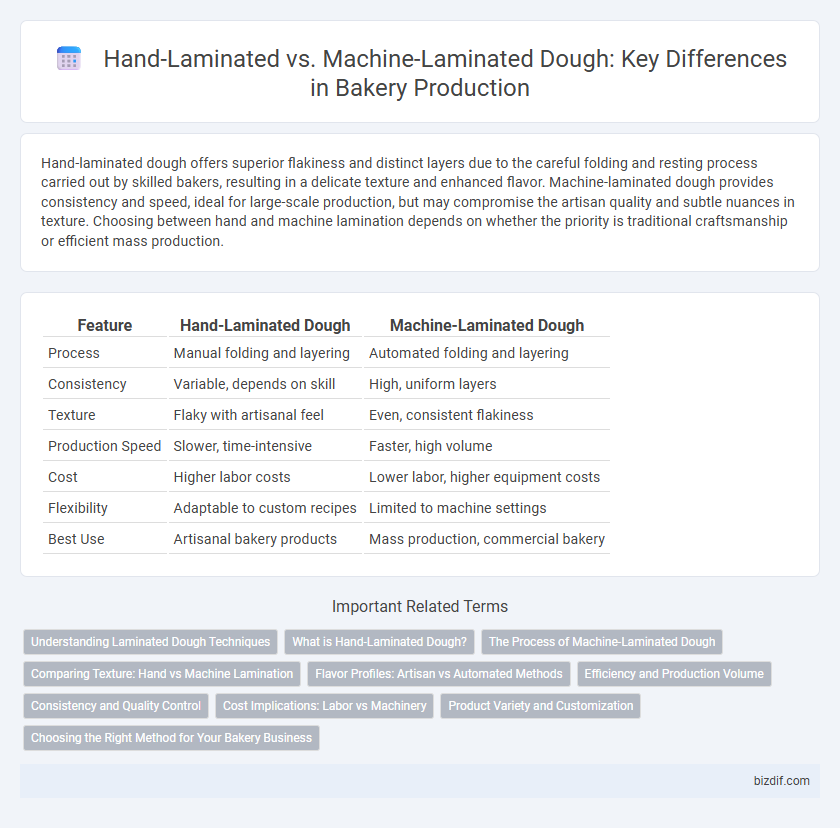

| Feature | Hand-Laminated Dough | Machine-Laminated Dough |

|---|---|---|

| Process | Manual folding and layering | Automated folding and layering |

| Consistency | Variable, depends on skill | High, uniform layers |

| Texture | Flaky with artisanal feel | Even, consistent flakiness |

| Production Speed | Slower, time-intensive | Faster, high volume |

| Cost | Higher labor costs | Lower labor, higher equipment costs |

| Flexibility | Adaptable to custom recipes | Limited to machine settings |

| Best Use | Artisanal bakery products | Mass production, commercial bakery |

Understanding Laminated Dough Techniques

Hand-laminated dough involves carefully folding butter into dough multiple times to create thin, flaky layers with a tender texture, often preferred for artisanal pastries due to its delicate crumb and intricate layering. Machine-laminated dough uses automated rollers and folders to achieve consistent lamination quickly, ideal for commercial bakeries seeking uniformity and higher production rates. Understanding laminated dough techniques requires recognizing the balance between manual skill that enhances flavor and texture, and mechanized precision that ensures efficiency and standardized quality.

What is Hand-Laminated Dough?

Hand-laminated dough is a traditional baking technique where layers of dough and butter are folded and rolled by hand to create delicate, flaky pastries such as croissants and puff pastries. This method allows precise control over the dough's texture and butter distribution, resulting in a superior crumb structure and enhanced flavor complexity. Highly skilled bakers rely on hand-lamination to achieve artisanal quality that machine-laminated dough often cannot replicate.

The Process of Machine-Laminated Dough

Machine-laminated dough involves the use of automated rollers and presses to layer butter and dough efficiently, ensuring consistent thickness and uniform lamination across batches. This mechanized process reduces preparation time while producing dough with evenly distributed fat, essential for achieving distinct flaky layers in pastries like croissants and puff pastry. Controlled temperature and precise timing in machine lamination minimize butter melting, preserving the integrity of laminated layers and resulting in superior texture and rise during baking.

Comparing Texture: Hand vs Machine Lamination

Hand-laminated dough typically produces a flakier and more delicate texture due to the careful, uneven folding that creates distinct, irregular layers of butter and dough. Machine-laminated dough yields a more uniform and consistent crumb structure but often lacks the nuanced airiness and slight crunch achieved through manual lamination. The artisanal quality of hand lamination enhances the sensory experience with a richer mouthfeel and varied layers, making it preferred in high-end patisserie products.

Flavor Profiles: Artisan vs Automated Methods

Hand-laminated dough produces complex, layered textures and rich, buttery flavors due to the slow, precise folding by skilled artisans. Machine-laminated dough, while consistent and efficient, often results in a more uniform crumb and a milder flavor profile lacking the nuanced depth of hand-crafted pastries. The artisan method enhances the flavor complexity by preserving delicate butter layers and encouraging natural fermentation, which automated processes may compromise.

Efficiency and Production Volume

Hand-laminated dough offers artisanal quality with precise dough layering but requires significant manual labor, limiting production volume and efficiency. Machine-laminated dough dramatically increases throughput and consistency, enabling bakeries to produce large batches rapidly while reducing labor costs. Industrial bakeries often prefer machine lamination to meet high demand and optimize operational efficiency.

Consistency and Quality Control

Hand-laminated dough offers artisanal texture variation and subtle flavor nuances due to manual folding, but this method can lead to inconsistencies in dough layers and thickness. Machine-laminated dough ensures precise, uniform layering with consistent gluten development, optimizing quality control and reproducibility in large-scale bakery production. Automated processes reduce human error, maintaining steady product quality essential for commercial bakery operations.

Cost Implications: Labor vs Machinery

Hand-laminated dough requires skilled labor, significantly increasing production costs due to longer preparation times and manual expertise involved. Machine-laminated dough reduces labor expenses by accelerating the lamination process and ensuring consistent quality, but it involves higher initial investment and maintenance costs for equipment. Balancing labor costs against machinery investment depends on production scale, with hand-lamination favored for artisanal batches and machine lamination optimal for large-scale commercial bakeries.

Product Variety and Customization

Hand-laminated dough allows bakers to produce unique, artisanal pastries with greater control over layering and texture, enabling a wider variety of specialty products. Machine-laminated dough offers consistent quality and speed but limits customization options due to standardized settings and processes. This makes hand lamination ideal for custom orders and small-batch varieties while machine lamination suits large-scale, uniform production.

Choosing the Right Method for Your Bakery Business

Hand-laminated dough offers artisanal texture and irregular, flaky layers that appeal to premium bakery products, while machine-laminated dough ensures consistency, speed, and higher volume production suitable for large-scale operations. Selecting the right method depends on your bakery's target market, production capacity, and desired product quality, with hand lamination favoring craftsmanship and machine lamination optimizing efficiency. Balancing these factors helps maximize profitability and meet customer expectations within your bakery business model.

Hand-laminated dough vs Machine-laminated dough Infographic

bizdif.com

bizdif.com