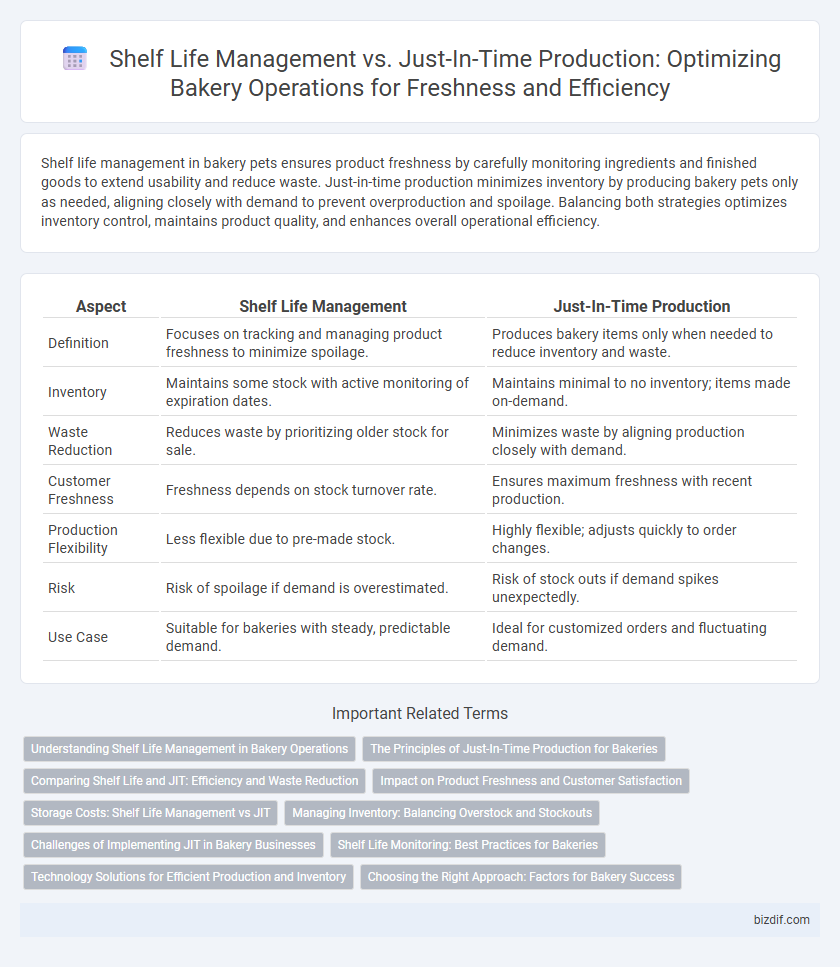

Shelf life management in bakery pets ensures product freshness by carefully monitoring ingredients and finished goods to extend usability and reduce waste. Just-in-time production minimizes inventory by producing bakery pets only as needed, aligning closely with demand to prevent overproduction and spoilage. Balancing both strategies optimizes inventory control, maintains product quality, and enhances overall operational efficiency.

Table of Comparison

| Aspect | Shelf Life Management | Just-In-Time Production |

|---|---|---|

| Definition | Focuses on tracking and managing product freshness to minimize spoilage. | Produces bakery items only when needed to reduce inventory and waste. |

| Inventory | Maintains some stock with active monitoring of expiration dates. | Maintains minimal to no inventory; items made on-demand. |

| Waste Reduction | Reduces waste by prioritizing older stock for sale. | Minimizes waste by aligning production closely with demand. |

| Customer Freshness | Freshness depends on stock turnover rate. | Ensures maximum freshness with recent production. |

| Production Flexibility | Less flexible due to pre-made stock. | Highly flexible; adjusts quickly to order changes. |

| Risk | Risk of spoilage if demand is overestimated. | Risk of stock outs if demand spikes unexpectedly. |

| Use Case | Suitable for bakeries with steady, predictable demand. | Ideal for customized orders and fluctuating demand. |

Understanding Shelf Life Management in Bakery Operations

Shelf life management in bakery operations involves monitoring the freshness and quality of products to minimize waste and ensure customer satisfaction, relying on accurate forecasting and inventory control. Unlike just-in-time production, which focuses on producing goods exactly when needed to reduce storage time, shelf life management emphasizes maintaining product viability through optimal storage conditions and rotation practices. Effective shelf life management reduces spoilage costs and supports sustainable bakery practices by extending the usability of baked goods.

The Principles of Just-In-Time Production for Bakeries

Just-In-Time (JIT) production in bakeries emphasizes producing baked goods precisely when needed to minimize inventory and reduce waste. Key principles include synchronizing ingredient deliveries with production schedules, maintaining minimal stock levels, and implementing continuous flow techniques to ensure freshness. By aligning production closely with demand, bakeries optimize shelf life, enhance product quality, and increase operational efficiency.

Comparing Shelf Life and JIT: Efficiency and Waste Reduction

Shelf life management in bakeries optimizes product freshness by closely monitoring expiration dates, reducing waste through timely sales, and minimizing inventory holding costs. Just-In-Time (JIT) production enhances efficiency by producing baked goods precisely when demand arises, thereby limiting overproduction and spoilage. Comparing both approaches, shelf life management emphasizes demand forecasting to balance stock levels, while JIT relies on synchronized supply chains to streamline production, collectively minimizing waste and maximizing profitability.

Impact on Product Freshness and Customer Satisfaction

Effective shelf life management in bakery operations ensures optimal product freshness by carefully balancing inventory turnover and spoilage rates, directly enhancing customer satisfaction through consistently fresh offerings. Just-In-time production minimizes waste by producing baked goods shortly before demand, maintaining peak quality and reducing the risk of stale inventory. Combining both strategies maximizes freshness and reliability, fostering stronger customer trust and repeat business.

Storage Costs: Shelf Life Management vs JIT

Shelf life management in bakeries reduces storage costs by minimizing inventory through precise forecasting and rotating stock before expiration, preventing waste. Just-In-Time (JIT) production further cuts storage expenses by producing baked goods only as needed, eliminating the need for large storage spaces. Optimizing these methods balances cost efficiency with product freshness and availability.

Managing Inventory: Balancing Overstock and Stockouts

Effective shelf life management in bakeries reduces waste by closely monitoring product freshness and expiration dates, ensuring timely sales before spoilage. Just-in-time production minimizes inventory holding costs by synchronizing baking schedules with customer demand, preventing overstock situations. Balancing these approaches requires integrating real-time sales data and precise demand forecasting to avoid stockouts while maintaining optimal inventory levels.

Challenges of Implementing JIT in Bakery Businesses

Implementing Just-In-Time (JIT) production in bakery businesses presents challenges such as the perishable nature of baked goods, which demands precise timing to minimize waste and avoid stockouts. Variability in ingredient delivery and unpredictable consumer demand complicate inventory coordination and can disrupt the baking schedule. Effective shelf life management systems must integrate real-time data on product freshness to enable responsive adjustments and maintain product quality.

Shelf Life Monitoring: Best Practices for Bakeries

Effective shelf life monitoring in bakeries ensures product freshness and reduces waste by tracking expiration dates and storage conditions rigorously. Implementing temperature-controlled environments and utilizing real-time inventory management software optimize shelf life and enhance product quality. Regular audits and staff training on proper handling practices further prevent spoilage and maintain customer satisfaction.

Technology Solutions for Efficient Production and Inventory

Shelf life management in bakeries relies heavily on technology solutions such as IoT sensors and AI-driven inventory systems to monitor product freshness and reduce waste. Just-in-time production integrates real-time data analytics and automated scheduling software to synchronize baking processes with demand, minimizing overproduction. Combining both approaches enhances efficiency by optimizing inventory turnover and ensuring timely product delivery while maintaining quality standards.

Choosing the Right Approach: Factors for Bakery Success

Shelf life management in bakeries ensures product freshness by controlling storage conditions and production schedules, reducing waste and maintaining quality. Just-in-time production minimizes inventory by aligning baking with demand, enhancing turnover and responsiveness to market trends. Selecting the ideal approach depends on factors such as product type, shelf life duration, customer demand variability, and operational capacity to balance freshness, cost-efficiency, and delivery speed.

Shelf Life Management vs Just-In-Time Production Infographic

bizdif.com

bizdif.com