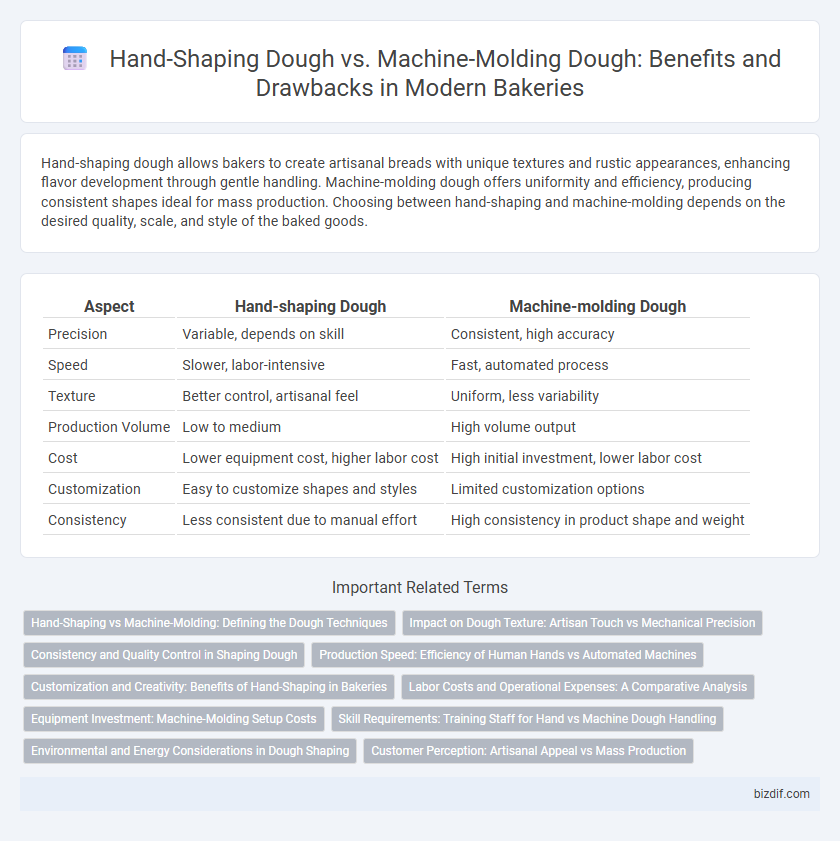

Hand-shaping dough allows bakers to create artisanal breads with unique textures and rustic appearances, enhancing flavor development through gentle handling. Machine-molding dough offers uniformity and efficiency, producing consistent shapes ideal for mass production. Choosing between hand-shaping and machine-molding depends on the desired quality, scale, and style of the baked goods.

Table of Comparison

| Aspect | Hand-shaping Dough | Machine-molding Dough |

|---|---|---|

| Precision | Variable, depends on skill | Consistent, high accuracy |

| Speed | Slower, labor-intensive | Fast, automated process |

| Texture | Better control, artisanal feel | Uniform, less variability |

| Production Volume | Low to medium | High volume output |

| Cost | Lower equipment cost, higher labor cost | High initial investment, lower labor cost |

| Customization | Easy to customize shapes and styles | Limited customization options |

| Consistency | Less consistent due to manual effort | High consistency in product shape and weight |

Hand-Shaping vs Machine-Molding: Defining the Dough Techniques

Hand-shaping dough involves manually stretching, folding, and forming dough to create artisanal textures and uneven, rustic crusts prized in traditional bakery products. Machine-molding dough automates this process, ensuring consistency and uniformity in size and shape, often preferred for mass production and standardized bread items. The choice between hand-shaping and machine-molding directly influences dough fermentation, gluten development, and final product quality in bakery operations.

Impact on Dough Texture: Artisan Touch vs Mechanical Precision

Hand-shaping dough in bakery preserves the artisan touch by allowing subtle pressure variations that create an open crumb and irregular bubbles, enhancing texture complexity. Machine-molding dough, driven by mechanical precision, ensures uniformity with consistent density and tighter crumb structure, ideal for mass production. The choice influences final bread texture, balancing handmade authenticity against standardized output.

Consistency and Quality Control in Shaping Dough

Hand-shaping dough allows for artisanal touch and subtle adjustments, but can lead to variability in consistency and shape due to human factors. Machine-molding dough ensures uniform size, weight, and shape across batches, significantly enhancing quality control and reducing product defects. Automated shaping processes contribute to standardized texture and baking performance, critical for large-scale bakery production.

Production Speed: Efficiency of Human Hands vs Automated Machines

Hand-shaping dough offers artisanal quality and customization but significantly slows production speed compared to machine-molding dough. Automated machines increase efficiency by producing thousands of uniform dough pieces per hour, optimizing bakery output for large-scale operations. Balancing handcraftsmanship with machine precision depends on bakery size, product type, and demand.

Customization and Creativity: Benefits of Hand-Shaping in Bakeries

Hand-shaping dough in bakeries enhances customization, allowing bakers to create unique textures, shapes, and designs that machines cannot replicate. This artisanal technique supports creativity by enabling adjustments based on dough consistency and desired appearance, leading to distinct, high-quality products. Hand-shaped dough often results in superior crust formation and a more authentic, handcrafted appeal valued by consumers.

Labor Costs and Operational Expenses: A Comparative Analysis

Hand-shaping dough involves higher labor costs due to the skill and time required for manual craftsmanship, contributing to increased operational expenses in artisanal bakeries. Machine-molding dough significantly reduces labor hours and operational overhead by automating repetitive tasks, enhancing production efficiency and consistency. Evaluating these methods reveals that machine-molding offers cost advantages for large-scale operations, while hand-shaping adds value through artisanal quality despite greater labor investments.

Equipment Investment: Machine-Molding Setup Costs

Machine-molding dough requires a significant initial investment in specialized equipment such as automated dough dividers, molders, and conveyors, which can cost upwards of $50,000 to $100,000 depending on capacity and features. Hand-shaping dough minimizes upfront expenses but increases labor costs and limits production speed, affecting overall efficiency in high-volume bakeries. Investing in machine-molding equipment often leads to faster throughput, consistent product sizes, and scalability, justifying the higher setup costs for commercial bakeries aiming to increase output.

Skill Requirements: Training Staff for Hand vs Machine Dough Handling

Hand-shaping dough demands skilled bakers with extensive training in tactile techniques, dough elasticity, and shape consistency, ensuring artisanal quality and unique textures. Machine-molding dough requires operators trained in equipment handling, calibration, and maintenance, emphasizing efficiency and uniformity in large-scale production. Investing in staff training for both methods improves dough quality, reduces waste, and enhances overall bakery productivity.

Environmental and Energy Considerations in Dough Shaping

Hand-shaping dough consumes significantly less energy compared to machine-molding, reducing the carbon footprint associated with bakery production. Manual techniques eliminate the need for electricity-intensive equipment, decreasing greenhouse gas emissions and reliance on fossil fuels. Sustainable baking practices favor hand-shaping for its lower environmental impact and energy efficiency.

Customer Perception: Artisanal Appeal vs Mass Production

Hand-shaping dough is often perceived by customers as a hallmark of artisanal craftsmanship, emphasizing authenticity and unique texture in baked goods. Machine-molding dough, while ensuring consistency and efficiency, can sometimes be viewed as mass production lacking the personal touch associated with traditional bakeries. Consumer preference tends to favor hand-shaped products for their perceived quality and heritage, enhancing brand loyalty in boutique bakery markets.

Hand-shaping Dough vs Machine-molding Dough Infographic

bizdif.com

bizdif.com