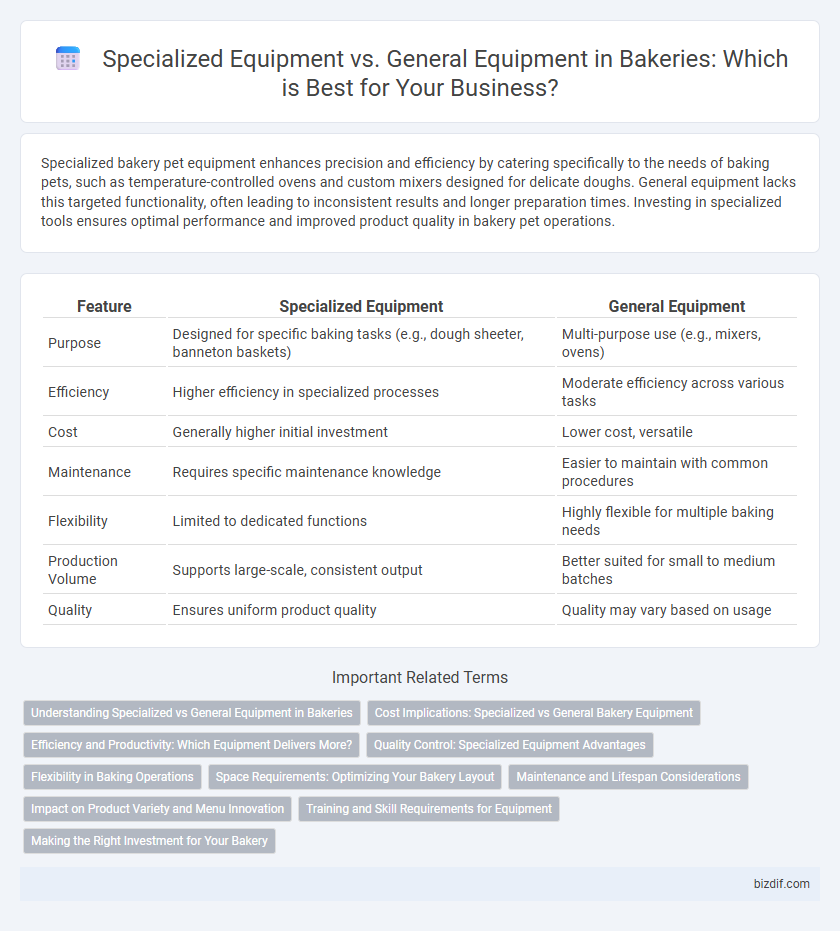

Specialized bakery pet equipment enhances precision and efficiency by catering specifically to the needs of baking pets, such as temperature-controlled ovens and custom mixers designed for delicate doughs. General equipment lacks this targeted functionality, often leading to inconsistent results and longer preparation times. Investing in specialized tools ensures optimal performance and improved product quality in bakery pet operations.

Table of Comparison

| Feature | Specialized Equipment | General Equipment |

|---|---|---|

| Purpose | Designed for specific baking tasks (e.g., dough sheeter, banneton baskets) | Multi-purpose use (e.g., mixers, ovens) |

| Efficiency | Higher efficiency in specialized processes | Moderate efficiency across various tasks |

| Cost | Generally higher initial investment | Lower cost, versatile |

| Maintenance | Requires specific maintenance knowledge | Easier to maintain with common procedures |

| Flexibility | Limited to dedicated functions | Highly flexible for multiple baking needs |

| Production Volume | Supports large-scale, consistent output | Better suited for small to medium batches |

| Quality | Ensures uniform product quality | Quality may vary based on usage |

Understanding Specialized vs General Equipment in Bakeries

Specialized equipment in bakeries, such as dough mixers, proofer cabinets, and deck ovens, is designed to enhance efficiency and product consistency, catering specifically to baking processes. General equipment like mixers, ovens, and refrigerators serve multiple purposes but may lack the precision or functionality needed for certain bakery tasks. Understanding the distinction helps bakery owners optimize workflow, improve product quality, and manage operational costs effectively.

Cost Implications: Specialized vs General Bakery Equipment

Specialized bakery equipment often entails higher upfront costs due to advanced features tailored for specific tasks like dough sheeting or croissant laminating, whereas general equipment offers versatility at a lower initial investment. Maintenance and repair expenses for specialized machines can be more costly, influenced by proprietary parts and skilled technician requirements. Investing in general equipment provides cost-effective flexibility for small-scale bakeries, while specialized equipment drives efficiency and product consistency in larger operations, justifying long-term higher expenses.

Efficiency and Productivity: Which Equipment Delivers More?

Specialized bakery equipment such as dough sheeters, proofer cabinets, and rotary ovens enhances efficiency by automating specific tasks, reducing manual labor, and ensuring consistent product quality. In contrast, general equipment like standard mixers and basic ovens offer versatility but may slow production due to less automation and longer preparation times. Investing in specialized tools typically increases productivity by streamlining workflows and minimizing errors, making them more effective for high-volume bakery operations.

Quality Control: Specialized Equipment Advantages

Specialized bakery equipment enhances quality control by providing precise temperature regulation and consistent mixing speeds, ensuring uniform dough texture and bake times. These machines often include built-in sensors and automation features that reduce human error and maintain product consistency batch after batch. Utilizing specialized equipment directly improves the overall product quality, leading to higher customer satisfaction and reduced waste.

Flexibility in Baking Operations

Specialized baking equipment, such as deck ovens and dough sheeters, enhances precision and consistency for specific products, streamlining high-volume production. General equipment, like convection ovens and mixers, offers greater flexibility, allowing bakeries to adapt quickly to a variety of recipes and product types. Balancing specialized and general equipment enables efficient scaling of operations while maintaining the ability to innovate and respond to market trends.

Space Requirements: Optimizing Your Bakery Layout

Specialized bakery equipment, such as dough sheeters and proofing cabinets, often requires dedicated and precise placement to maximize efficiency in limited kitchen space. In contrast, general equipment like mixers and ovens can be more flexibly arranged, allowing for adaptable layout adjustments as production demands change. Evaluating space requirements for each type of equipment ensures optimal workflow, reduces clutter, and enhances productivity in bakery operations.

Maintenance and Lifespan Considerations

Specialized bakery equipment, such as dough sheeters and proofer cabinets, typically requires targeted maintenance protocols to ensure optimal performance and longevity, as their complex mechanisms are designed for specific tasks. General equipment, like mixers and ovens, offers versatility but may suffer faster wear if used beyond intended purposes, leading to increased maintenance frequency and potentially shorter lifespan. Investing in specialized equipment can reduce downtime and repair costs through enhanced durability and tailored upkeep, maximizing operational efficiency in commercial bakery settings.

Impact on Product Variety and Menu Innovation

Specialized bakery equipment, such as dough sheeters and proofing cabinets, enables precise product consistency and supports the creation of niche items like croissants and artisan bread, thereby expanding menu variety. In contrast, general equipment like standard mixers and ovens offers versatility but may limit the complexity and uniqueness of baked goods, potentially restricting menu innovation. Investing in specialized tools directly correlates with the ability to experiment with diverse recipes and introduce innovative products that attract broader customer segments.

Training and Skill Requirements for Equipment

Specialized bakery equipment such as dough sheeters and spiral mixers demand advanced training and specific skill sets to operate effectively, ensuring consistent product quality. General equipment like hand mixers or standard ovens require minimal training, making them accessible to a broader range of employees with basic baking knowledge. Investing in training for specialized machinery enhances efficiency and precision but involves a steeper learning curve compared to general equipment.

Making the Right Investment for Your Bakery

Choosing specialized equipment like dough sheeters and proofing cabinets enhances efficiency and product consistency in bakeries, directly impacting quality and output. General equipment such as mixers and ovens offers versatility for various baking tasks, reducing upfront costs and space requirements. Balancing these investments ensures optimal workflow, cost management, and the ability to meet specific bakery product demands.

Specialized Equipment vs General Equipment Infographic

bizdif.com

bizdif.com