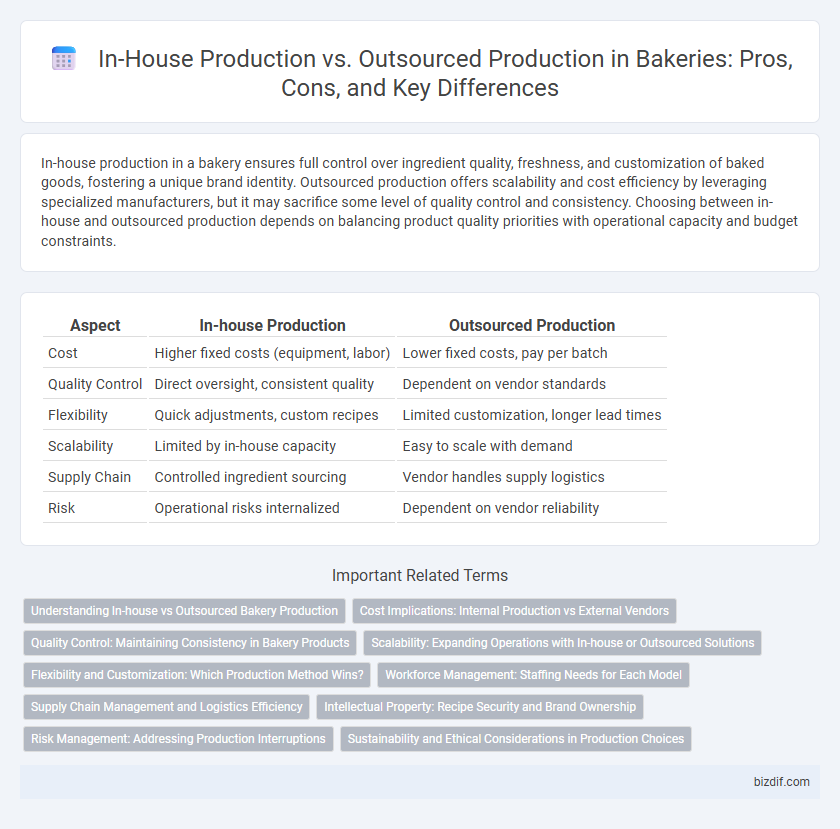

In-house production in a bakery ensures full control over ingredient quality, freshness, and customization of baked goods, fostering a unique brand identity. Outsourced production offers scalability and cost efficiency by leveraging specialized manufacturers, but it may sacrifice some level of quality control and consistency. Choosing between in-house and outsourced production depends on balancing product quality priorities with operational capacity and budget constraints.

Table of Comparison

| Aspect | In-house Production | Outsourced Production |

|---|---|---|

| Cost | Higher fixed costs (equipment, labor) | Lower fixed costs, pay per batch |

| Quality Control | Direct oversight, consistent quality | Dependent on vendor standards |

| Flexibility | Quick adjustments, custom recipes | Limited customization, longer lead times |

| Scalability | Limited by in-house capacity | Easy to scale with demand |

| Supply Chain | Controlled ingredient sourcing | Vendor handles supply logistics |

| Risk | Operational risks internalized | Dependent on vendor reliability |

Understanding In-house vs Outsourced Bakery Production

In-house bakery production offers greater control over ingredient quality, recipe customization, and consistency, enabling bakeries to maintain unique flavors and brand identity. Outsourced production reduces labor costs and increases scalability by leveraging specialized manufacturers, but may compromise freshness and flexibility in product offerings. Evaluating production strategies involves balancing cost efficiency, quality control, and delivery timelines to meet consumer demand effectively.

Cost Implications: Internal Production vs External Vendors

In-house production in bakeries often incurs higher upfront costs due to labor, ingredient sourcing, and equipment maintenance but allows for greater quality control and customization. Outsourcing to external vendors typically reduces variable expenses and capital investments, benefiting from economies of scale and streamlined supply chains. Careful cost-benefit analysis considering overhead, production volume, and product consistency is crucial for optimizing bakery profitability.

Quality Control: Maintaining Consistency in Bakery Products

In-house production in bakeries ensures strict quality control by allowing direct supervision of ingredient selection, baking processes, and final product inspection, which maintains consistent texture and flavor. Outsourced production may introduce variability due to differences in baking standards and ingredient sourcing, potentially compromising product uniformity. Consistency in bakery products relies heavily on meticulous quality checks that are more effectively managed within an in-house production environment.

Scalability: Expanding Operations with In-house or Outsourced Solutions

In-house production offers greater control and customization but may face limitations in scalability due to equipment and labor constraints. Outsourced production enables rapid scaling by leveraging established facilities and workforce, facilitating response to fluctuating demand without heavy capital investment. Choosing the optimal approach depends on balancing growth goals with cost efficiency and operational flexibility within the bakery industry.

Flexibility and Customization: Which Production Method Wins?

In-house bakery production offers superior flexibility and customization, allowing bakeries to quickly adjust recipes and create unique products tailored to customer preferences. Outsourced production often limits customization options due to standardized processes and bulk manufacturing constraints. Therefore, bakeries aiming for bespoke offerings and agile product development benefit significantly from maintaining in-house production capabilities.

Workforce Management: Staffing Needs for Each Model

In-house production requires a dedicated workforce skilled in diverse baking techniques, enabling precise quality control but demanding higher staffing levels and training investment. Outsourced production minimizes direct staffing needs, shifting workforce management responsibilities to external suppliers, which reduces labor costs but may limit flexibility and oversight. Effective workforce management balances operational efficiency with production demands, ensuring timely output and product consistency regardless of the chosen model.

Supply Chain Management and Logistics Efficiency

In-house production in bakeries allows for tighter control over supply chain management, improving ingredient quality, inventory accuracy, and production scheduling, which optimizes logistics efficiency by reducing lead times and transportation costs. Outsourced production can introduce variability in supply chain reliability and increase logistical complexity due to dependency on external suppliers and longer delivery routes. Effective coordination and real-time communication platforms are crucial to mitigate delays and maintain consistent product quality whether production is in-house or outsourced.

Intellectual Property: Recipe Security and Brand Ownership

In-house production in bakery ensures stronger control over intellectual property by safeguarding proprietary recipes and techniques, preventing unauthorized use or replication. Outsourced production increases risks of recipe leaks and brand dilution, as third parties may access or misuse confidential formulations. Maintaining brand ownership and recipe security is critical for preserving competitive advantage and customer trust within the bakery industry.

Risk Management: Addressing Production Interruptions

In-house bakery production allows for greater control over risk management by enabling immediate response to equipment failure or ingredient shortages, minimizing production interruptions. Outsourced production, while potentially reducing fixed costs, introduces dependencies on third-party schedules and quality controls, increasing the risk of delays or inconsistent product availability. Implementing robust contingency plans and maintaining transparent communication channels are critical to mitigating risks associated with both production models.

Sustainability and Ethical Considerations in Production Choices

In-house production in bakeries enables closer control over sustainable sourcing and waste reduction practices, ensuring ethically sourced ingredients and minimizing environmental impact. Outsourced production often faces challenges in transparency, making it harder to verify suppliers' adherence to fair labor standards and eco-friendly methods. Prioritizing in-house baking supports local economies and reduces carbon footprints by limiting transportation emissions and packaging waste.

In-house production vs Outsourced production Infographic

bizdif.com

bizdif.com