Laminate dough involves folding layers of butter into the dough to create a flaky, airy texture ideal for pastries like croissants and Danish. Straight dough combines all ingredients in one step, resulting in a denser, more uniform crumb suitable for breads and rolls. Choosing between laminate and straight dough depends on the desired texture and final product in bakery pet creations.

Table of Comparison

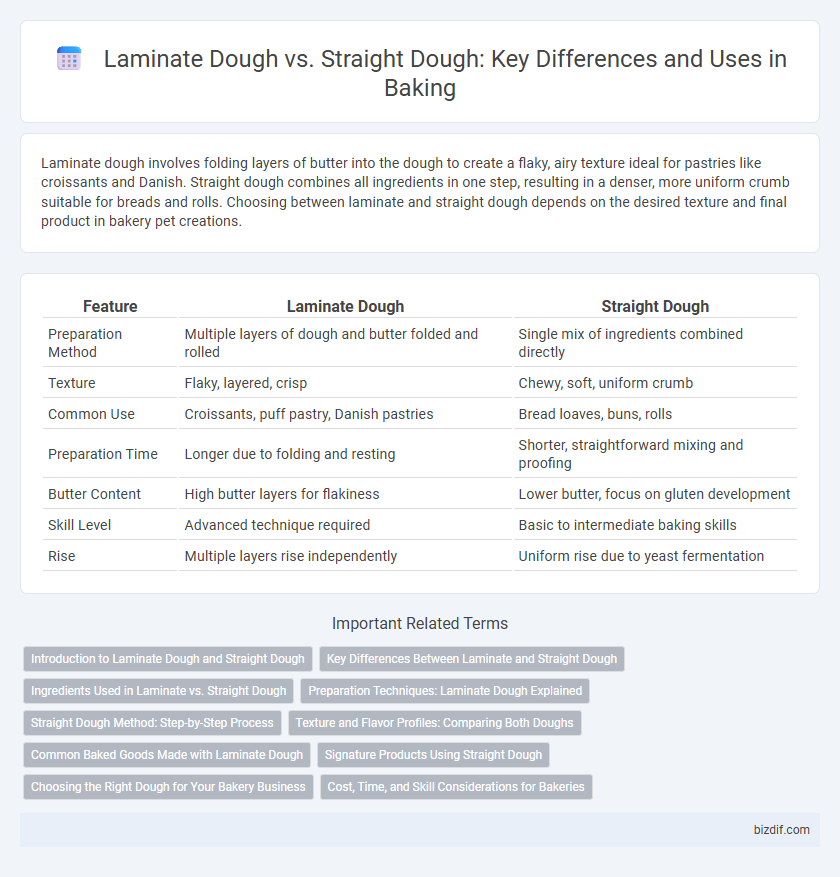

| Feature | Laminate Dough | Straight Dough |

|---|---|---|

| Preparation Method | Multiple layers of dough and butter folded and rolled | Single mix of ingredients combined directly |

| Texture | Flaky, layered, crisp | Chewy, soft, uniform crumb |

| Common Use | Croissants, puff pastry, Danish pastries | Bread loaves, buns, rolls |

| Preparation Time | Longer due to folding and resting | Shorter, straightforward mixing and proofing |

| Butter Content | High butter layers for flakiness | Lower butter, focus on gluten development |

| Skill Level | Advanced technique required | Basic to intermediate baking skills |

| Rise | Multiple layers rise independently | Uniform rise due to yeast fermentation |

Introduction to Laminate Dough and Straight Dough

Laminate dough consists of alternating layers of dough and butter, creating a flaky texture essential for croissants and puff pastries. Straight dough involves mixing all ingredients in one step, resulting in a denser, more uniform crumb typical of breads like sandwich loaves. Understanding the differences between laminate and straight dough is crucial for bakers aiming to achieve specific textures and flavors in their baked goods.

Key Differences Between Laminate and Straight Dough

Laminate dough involves layering butter and dough through folding and rolling, creating flaky pastries like croissants, while straight dough combines all ingredients in a single mix, resulting in uniform, denser bread. Laminate dough requires precise temperature control to maintain butter layers, whereas straight dough is simpler and faster to prepare. The structural difference influences texture and flakiness, making laminate dough ideal for puff pastries and straight dough suited for traditional bread loaves.

Ingredients Used in Laminate vs. Straight Dough

Laminate dough uses layers of butter folded into the dough, creating a high fat content that results in a flaky, tender texture, often seen in croissants and puff pastries. Straight dough relies on a simple mixture of flour, water, yeast, sugar, salt, and fat, typically oil or butter, mixed all at once for a denser, chewier crumb ideal for breads and rolls. The primary ingredient difference is the incorporation of large quantities of butter in laminate dough compared to the minimal, fully integrated fat in straight dough.

Preparation Techniques: Laminate Dough Explained

Laminate dough involves a meticulous preparation technique where layers of butter are folded into the dough through a repeated rolling and folding process, creating a flaky, airy texture ideal for pastries like croissants and puff pastry. Straight dough preparation mixes all ingredients uniformly without layering, resulting in denser breads such as sandwich loaves. The lamination process critically impacts the final product's texture, requiring precise temperature control to prevent butter melting and ensure distinct, crisp layers.

Straight Dough Method: Step-by-Step Process

The Straight Dough Method involves mixing all ingredients simultaneously, allowing for a more straightforward and efficient dough preparation compared to Laminate Dough. This process typically includes combining flour, water, yeast, salt, and other ingredients, followed by kneading, fermenting, shaping, proofing, and finally baking. Mastery of temperature control and fermentation time is essential to achieve optimal texture and flavor in bread using the Straight Dough Method.

Texture and Flavor Profiles: Comparing Both Doughs

Laminate dough produces a flaky, layered texture with rich, buttery flavor due to the repeated folding of dough and butter, making it ideal for croissants and puff pastries. Straight dough yields a denser crumb with a more robust, yeasty flavor, commonly used in bread and rolls where a chewy texture is desired. The choice between laminate and straight dough directly influences the final product's mouthfeel and flavor complexity, catering to distinct baking purposes.

Common Baked Goods Made with Laminate Dough

Laminate dough is essential for creating flaky pastries such as croissants, Danish pastries, and puff pastry-based items, offering distinct layers and a tender crumb texture. Unlike straight dough, which is typically used for bread and rolls, laminate dough involves folding butter into the dough multiple times to achieve its characteristic flakiness. Popular bakery products featuring laminate dough include mille-feuille, kouign-amann, and palmiers, celebrated for their delicate, buttery layers.

Signature Products Using Straight Dough

Signature bakery products using straight dough include classic breads like French baguettes, sandwich loaves, and rustic country bread, prized for their simple, robust flavor and chewy texture. Straight dough method involves mixing all ingredients together in one step, leading to a more straightforward fermentation process that enhances natural yeast activity and gluten development. This technique is favored for its efficiency and consistent results, producing breads with a well-balanced crumb and extended shelf life.

Choosing the Right Dough for Your Bakery Business

Choosing the right dough for your bakery business depends on factors like production scale, desired texture, and flavor complexity. Laminate dough, known for its multiple layers created by folding butter into the dough, produces flaky pastries such as croissants, ideal for premium offerings. Straight dough, simpler and quicker to prepare, suits high-volume production and yields soft, airy breads like sandwich loaves, optimizing efficiency and cost.

Cost, Time, and Skill Considerations for Bakeries

Laminate dough requires higher skill levels and longer preparation time due to multiple folding and chilling stages, increasing labor costs and production complexity in bakeries. Straight dough methods are more cost-effective, faster to prepare, and ideal for large-scale production with less skilled staff. Choosing between laminate and straight dough depends on balancing product quality with operational efficiency and budget constraints in bakery operations.

Laminate dough vs Straight dough Infographic

bizdif.com

bizdif.com