Onsite bakery production ensures fresh, handcrafted products made daily, enhancing quality and customer satisfaction with immediate availability. Centralized production offers cost efficiency and consistent product quality through bulk preparation and streamlined processes. Choosing between onsite and centralized production depends on balancing freshness, operational efficiency, and scale of demand.

Table of Comparison

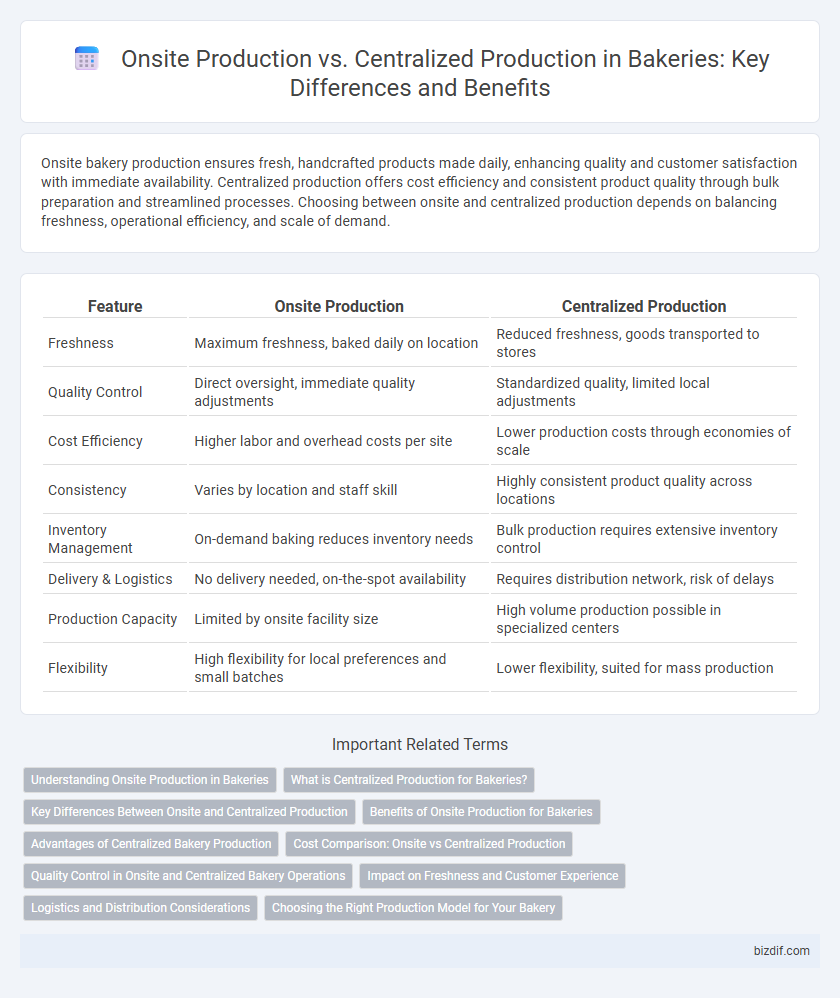

| Feature | Onsite Production | Centralized Production |

|---|---|---|

| Freshness | Maximum freshness, baked daily on location | Reduced freshness, goods transported to stores |

| Quality Control | Direct oversight, immediate quality adjustments | Standardized quality, limited local adjustments |

| Cost Efficiency | Higher labor and overhead costs per site | Lower production costs through economies of scale |

| Consistency | Varies by location and staff skill | Highly consistent product quality across locations |

| Inventory Management | On-demand baking reduces inventory needs | Bulk production requires extensive inventory control |

| Delivery & Logistics | No delivery needed, on-the-spot availability | Requires distribution network, risk of delays |

| Production Capacity | Limited by onsite facility size | High volume production possible in specialized centers |

| Flexibility | High flexibility for local preferences and small batches | Lower flexibility, suited for mass production |

Understanding Onsite Production in Bakeries

Onsite production in bakeries involves baking products directly at the retail location, ensuring fresher goods and immediate customization based on local customer preferences. This approach reduces transportation time and costs, enhances product quality through direct quality control, and allows for rapid response to demand fluctuations. Onsite production supports artisanal techniques and creates a unique customer experience by showcasing the baking process in real-time.

What is Centralized Production for Bakeries?

Centralized production for bakeries involves manufacturing baked goods in a single, large-scale facility that supplies multiple retail locations or distribution centers. This method enhances consistency, operational efficiency, and cost control by consolidating baking processes, ingredient procurement, and quality management in one central kitchen. Centralized production systems enable bakeries to scale output, maintain standardized product quality, and streamline supply chain logistics.

Key Differences Between Onsite and Centralized Production

Onsite production in a bakery involves baking goods directly at the retail location, ensuring freshness and immediate availability, while centralized production relies on a single, large facility to produce items for multiple outlets, emphasizing efficiency and consistency. Onsite production allows for customization and quick response to customer demand, whereas centralized production benefits from economies of scale and standardized quality control. Inventory management in onsite bakeries tends to be more flexible but complex, contrasting with the streamlined logistics and cost-effectiveness of centralized distribution.

Benefits of Onsite Production for Bakeries

Onsite production in bakeries enhances product freshness by enabling immediate baking and delivery, which significantly improves customer satisfaction and taste quality. It allows greater flexibility to customize products based on local preferences and seasonal ingredients, fostering a unique brand identity. Furthermore, onsite production reduces transportation costs and risks of product damage, contributing to cost efficiency and sustainability.

Advantages of Centralized Bakery Production

Centralized bakery production enhances consistency and quality control by standardizing recipes and processes across multiple locations. It reduces operational costs through economies of scale, including bulk purchasing of ingredients and shared labor resources. Centralized production also streamlines inventory management and minimizes waste, contributing to increased overall efficiency.

Cost Comparison: Onsite vs Centralized Production

Onsite bakery production often incurs higher labor and equipment maintenance costs due to smaller batch sizes and less automation compared to centralized production facilities, which benefit from economies of scale and streamlined logistics. Centralized production reduces per-unit costs by leveraging bulk purchasing of raw materials and consistent manufacturing processes, minimizing waste and improving efficiency. However, onsite production can offset some costs by lowering transportation expenses and ensuring fresher products tailored to local demand.

Quality Control in Onsite and Centralized Bakery Operations

Onsite production in bakery operations allows for real-time quality control, ensuring freshness and immediate adjustment to customer preferences, which enhances product consistency. Centralized production benefits from standardized processes and automated quality checks, leading to scalable and uniform output but may face challenges with product freshness during distribution. Effective quality control systems in both onsite and centralized bakeries are crucial for maintaining food safety standards and meeting consumer expectations.

Impact on Freshness and Customer Experience

Onsite production ensures optimal freshness by baking products directly at the retail location, minimizing transportation time and preserving flavor and texture. Centralized production allows for consistent quality and streamlined operations but may compromise freshness due to longer delivery times and storage requirements. Customers typically perceive onsite-baked goods as higher quality, enhancing satisfaction and encouraging repeat visits.

Logistics and Distribution Considerations

Onsite production in bakeries reduces transportation costs and minimizes product freshness loss, ensuring faster delivery to customers. Centralized production allows for bulk ingredient purchasing and consistent quality control but requires robust logistics networks to manage longer distribution routes and refrigeration needs. Efficient route planning and temperature-controlled vehicles are essential to maintain product integrity when distributing from a central facility to multiple retail locations.

Choosing the Right Production Model for Your Bakery

Choosing the right production model for your bakery hinges on factors such as product variety, scale, and quality control. Onsite production allows fresh, customized goods with immediate quality checks, ideal for artisan bakeries with diverse offerings. Centralized production enhances efficiency and consistency, suitable for larger operations focused on volume and streamlined distribution.

Onsite Production vs Centralized Production Infographic

bizdif.com

bizdif.com