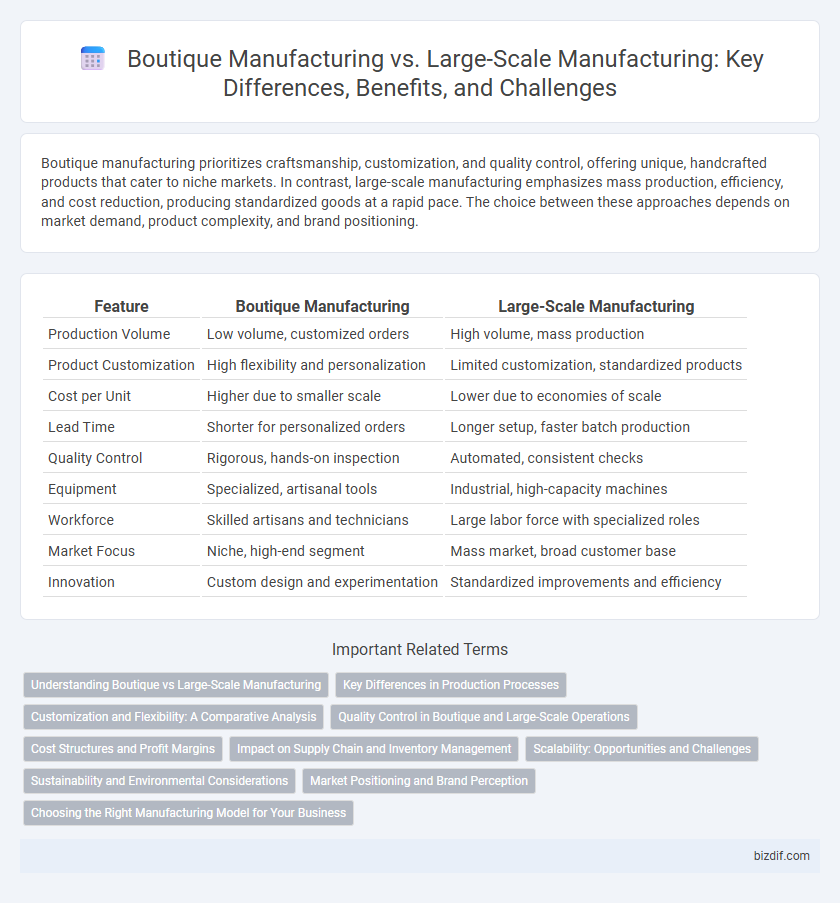

Boutique manufacturing prioritizes craftsmanship, customization, and quality control, offering unique, handcrafted products that cater to niche markets. In contrast, large-scale manufacturing emphasizes mass production, efficiency, and cost reduction, producing standardized goods at a rapid pace. The choice between these approaches depends on market demand, product complexity, and brand positioning.

Table of Comparison

| Feature | Boutique Manufacturing | Large-Scale Manufacturing |

|---|---|---|

| Production Volume | Low volume, customized orders | High volume, mass production |

| Product Customization | High flexibility and personalization | Limited customization, standardized products |

| Cost per Unit | Higher due to smaller scale | Lower due to economies of scale |

| Lead Time | Shorter for personalized orders | Longer setup, faster batch production |

| Quality Control | Rigorous, hands-on inspection | Automated, consistent checks |

| Equipment | Specialized, artisanal tools | Industrial, high-capacity machines |

| Workforce | Skilled artisans and technicians | Large labor force with specialized roles |

| Market Focus | Niche, high-end segment | Mass market, broad customer base |

| Innovation | Custom design and experimentation | Standardized improvements and efficiency |

Understanding Boutique vs Large-Scale Manufacturing

Boutique manufacturing emphasizes customized, small-batch production tailored to niche markets, allowing for greater flexibility and higher quality control. Large-scale manufacturing prioritizes mass production with standardized processes to achieve economies of scale and lower per-unit costs. Understanding these differences helps businesses choose between personalized craftsmanship and efficient volume output based on market demands and product complexity.

Key Differences in Production Processes

Boutique manufacturing emphasizes handcrafted, small-batch production tailored to niche markets, resulting in high customization and quality control. Large-scale manufacturing relies on automated, assembly-line processes designed for mass production, optimizing efficiency and reducing unit costs. These contrasting production approaches impact flexibility, lead times, and customer personalization significantly.

Customization and Flexibility: A Comparative Analysis

Boutique manufacturing excels in customization and flexibility by producing limited quantities tailored to specific client needs, often using skilled artisans and adaptable processes. Large-scale manufacturing prioritizes high-volume output and cost efficiency, relying on standardized designs and automated systems that limit customization options. The boutique approach enables rapid adjustments and personalized products, while large-scale methods focus on consistency and economies of scale.

Quality Control in Boutique and Large-Scale Operations

Boutique manufacturing emphasizes meticulous quality control with handcrafted precision and personalized oversight, ensuring each product meets exacting standards. Large-scale manufacturing relies on standardized processes and automated inspections to maintain consistent quality across vast production volumes. Differences in quality control strategies affect product uniqueness, defect rates, and customer satisfaction levels in boutique versus mass production environments.

Cost Structures and Profit Margins

Boutique manufacturing typically incurs higher per-unit costs due to specialized materials and labor-intensive processes, resulting in narrower profit margins compared to large-scale manufacturing. Large-scale manufacturing leverages economies of scale, reducing fixed and variable costs through bulk purchasing and automated production lines, which enhances profit margins. However, boutique manufacturers often charge premium prices for customization and exclusivity that can offset higher costs and sustain profitability.

Impact on Supply Chain and Inventory Management

Boutique manufacturing offers highly customized products that require flexible supply chain strategies and lean inventory management to respond rapidly to changing customer demands. Large-scale manufacturing emphasizes standardized production processes, enabling bulk procurement and extensive inventory storage, which reduces per-unit costs but increases inventory holding risks. The supply chain in boutique settings prioritizes agility and supplier collaboration, while large-scale operations depend on efficiency and economies of scale for inventory management.

Scalability: Opportunities and Challenges

Boutique manufacturing offers high customization and agility, enabling rapid adaptation to market trends but faces limitations in scalability due to higher per-unit costs and resource constraints. Large-scale manufacturing benefits from economies of scale, significantly reducing production costs and enabling mass distribution, yet struggles with flexibility and slower response to niche market demands. Balancing these factors requires strategic investment in technology and process optimization to enhance scalability without compromising quality or innovation.

Sustainability and Environmental Considerations

Boutique manufacturing emphasizes sustainable practices by using eco-friendly materials and minimizing waste through limited production runs, which significantly reduces the environmental footprint compared to large-scale manufacturing. Large-scale operations often rely on mass production techniques that can lead to excessive resource consumption and higher greenhouse gas emissions. By prioritizing local sourcing and handcrafted methods, boutique manufacturers significantly contribute to environmental preservation and sustainability initiatives.

Market Positioning and Brand Perception

Boutique manufacturing emphasizes exclusivity and craftsmanship, positioning brands as premium and artisanal in the market. This approach fosters strong customer loyalty and allows for personalized marketing strategies that highlight uniqueness and quality. In contrast, large-scale manufacturing targets mass markets with standardized products, often perceived as more affordable but less distinctive in brand identity.

Choosing the Right Manufacturing Model for Your Business

Boutique manufacturing offers customized, high-quality products with a focus on craftsmanship and flexibility, making it ideal for niche markets and unique brand identities. Large-scale manufacturing excels in cost efficiency and mass production, suitable for businesses targeting broad markets and consistent volume demands. Selecting the right manufacturing model depends on product complexity, target audience, production volume, and budget, ensuring alignment with business goals and growth strategy.

Boutique Manufacturing vs Large-Scale Manufacturing Infographic

bizdif.com

bizdif.com