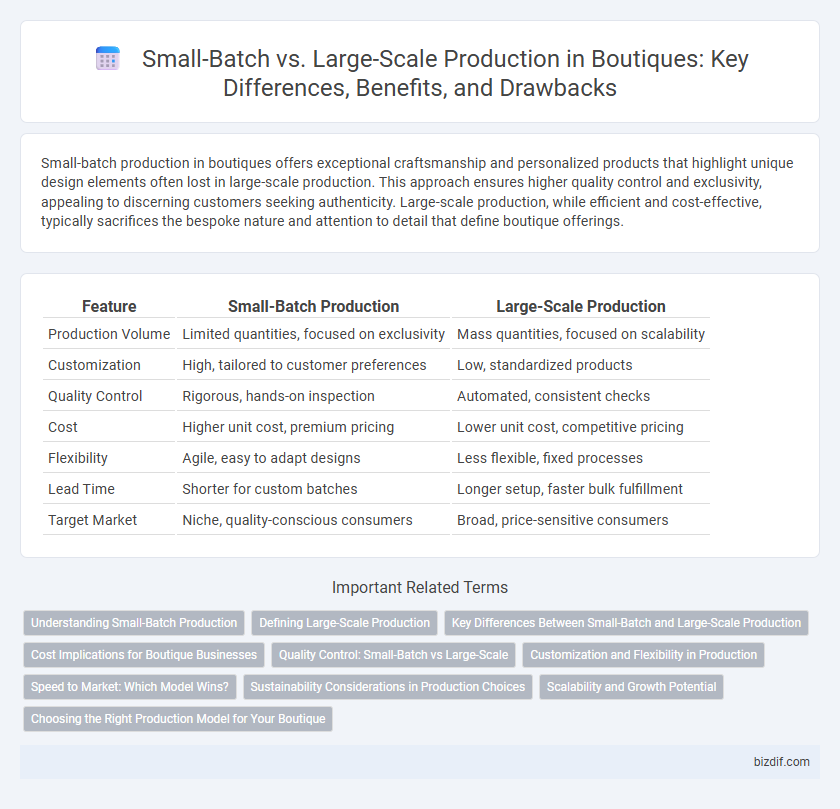

Small-batch production in boutiques offers exceptional craftsmanship and personalized products that highlight unique design elements often lost in large-scale production. This approach ensures higher quality control and exclusivity, appealing to discerning customers seeking authenticity. Large-scale production, while efficient and cost-effective, typically sacrifices the bespoke nature and attention to detail that define boutique offerings.

Table of Comparison

| Feature | Small-Batch Production | Large-Scale Production |

|---|---|---|

| Production Volume | Limited quantities, focused on exclusivity | Mass quantities, focused on scalability |

| Customization | High, tailored to customer preferences | Low, standardized products |

| Quality Control | Rigorous, hands-on inspection | Automated, consistent checks |

| Cost | Higher unit cost, premium pricing | Lower unit cost, competitive pricing |

| Flexibility | Agile, easy to adapt designs | Less flexible, fixed processes |

| Lead Time | Shorter for custom batches | Longer setup, faster bulk fulfillment |

| Target Market | Niche, quality-conscious consumers | Broad, price-sensitive consumers |

Understanding Small-Batch Production

Small-batch production emphasizes crafting limited quantities of products, allowing for greater quality control, customization, and flexibility compared to large-scale production. This approach is ideal for boutiques seeking to maintain exclusivity, reduce waste, and quickly adapt to market trends. Small-batch techniques often involve artisanal methods and careful attention to detail, resulting in unique, high-quality goods that appeal to discerning customers.

Defining Large-Scale Production

Large-scale production refers to the manufacturing of goods in extensive quantities using advanced machinery, automated processes, and assembly lines to maximize efficiency and reduce per-unit costs. This method is common in industries like automotive, electronics, and consumer goods, where consistent quality and high output are crucial. Large-scale production contrasts with small-batch or boutique production by prioritizing volume, standardization, and economies of scale.

Key Differences Between Small-Batch and Large-Scale Production

Small-batch production emphasizes artisanal quality with limited quantities, allowing for greater customization and faster adaptation to market trends. Large-scale production focuses on mass output, leveraging economies of scale to lower costs and maintain consistent product standards across extensive distribution channels. The key differences lie in production volume, flexibility, cost per unit, and the degree of personalization available to consumers.

Cost Implications for Boutique Businesses

Small-batch production in boutique businesses often results in higher per-unit costs due to limited economies of scale and increased material expenses, impacting overall profitability. Large-scale production reduces costs through bulk purchasing and streamlined processes but may compromise the unique quality and exclusivity valued by boutique clientele. Balancing production scale with cost management is essential for boutiques aiming to maintain brand integrity while achieving sustainable margins.

Quality Control: Small-Batch vs Large-Scale

Small-batch production prioritizes meticulous quality control by allowing artisans to closely monitor each item, reducing defects and ensuring superior craftsmanship. In contrast, large-scale production often relies on automated processes that may lead to inconsistencies due to the high volume and speed of output. Boutique brands leveraging small-batch methods achieve higher product integrity and personalized detailing, setting them apart from mass-produced counterparts.

Customization and Flexibility in Production

Small-batch production enables high customization and flexibility, allowing boutiques to tailor products precisely to customer preferences and respond quickly to market trends. In contrast, large-scale production prioritizes uniformity and cost-efficiency, often sacrificing the ability to make personalized adjustments. Boutiques leveraging small-batch methods benefit from unique, limited-edition offerings that enhance brand exclusivity and customer loyalty.

Speed to Market: Which Model Wins?

Small-batch production offers faster speed to market due to its agile manufacturing processes and ability to rapidly adjust to design changes or trends. Large-scale production, although efficient in volume, often requires longer lead times for setup and quality control, delaying product launch. For boutiques prioritizing quick market entry and responsiveness, small-batch production typically ensures a competitive advantage.

Sustainability Considerations in Production Choices

Small-batch production in boutique settings minimizes waste and reduces energy consumption by producing limited quantities tailored to demand, enhancing sustainability. Large-scale production often involves resource-intensive processes and higher carbon footprints due to mass manufacturing and extended supply chains. Prioritizing small-batch methods supports eco-friendly practices, including local sourcing and ethical labor, aligning with sustainability goals.

Scalability and Growth Potential

Small-batch production enables boutiques to maintain high-quality craftsmanship and exclusivity, but scalability is limited due to resource-intensive processes. Large-scale production offers significant growth potential by leveraging automation and economies of scale, allowing rapid expansion to meet increasing demand. Balancing boutique exclusivity with scalable manufacturing strategies is essential for sustainable growth.

Choosing the Right Production Model for Your Boutique

Small-batch production offers boutiques the advantage of exclusivity, higher quality control, and the ability to quickly adapt to market trends, making it ideal for niche or high-end markets. Large-scale production can reduce costs per unit and ensure consistent supply, but may compromise uniqueness and flexibility essential for boutique branding. Evaluating customer demand, budget constraints, and brand identity is crucial when selecting between small-batch and large-scale production models for a boutique.

Small-Batch Production vs Large-Scale Production Infographic

bizdif.com

bizdif.com